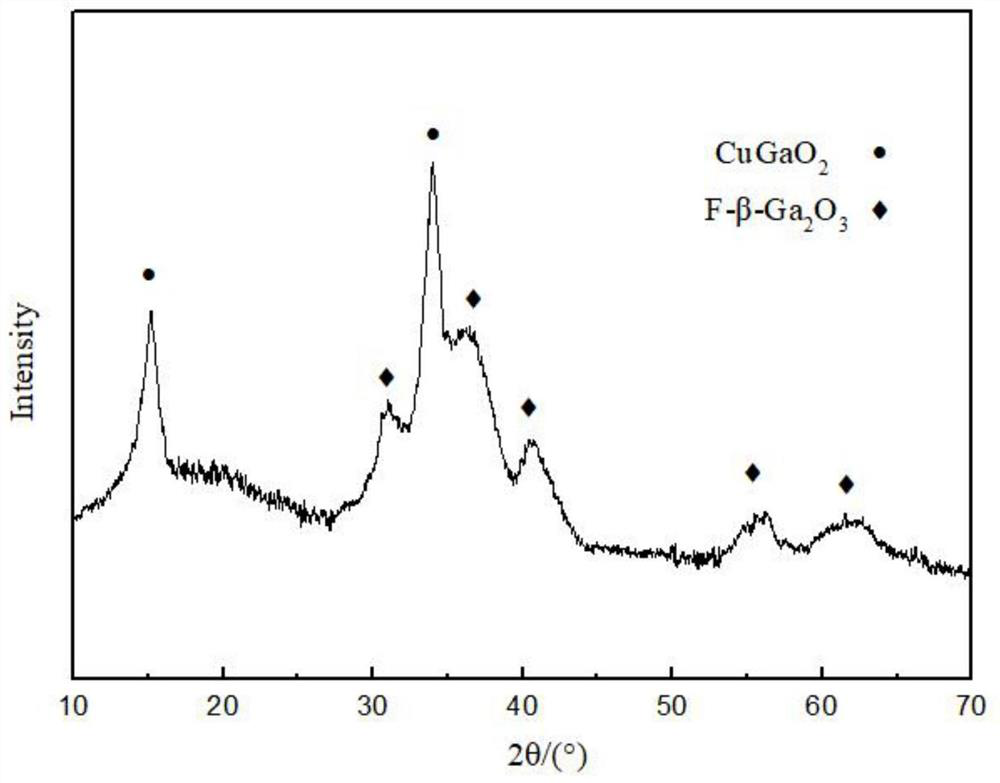

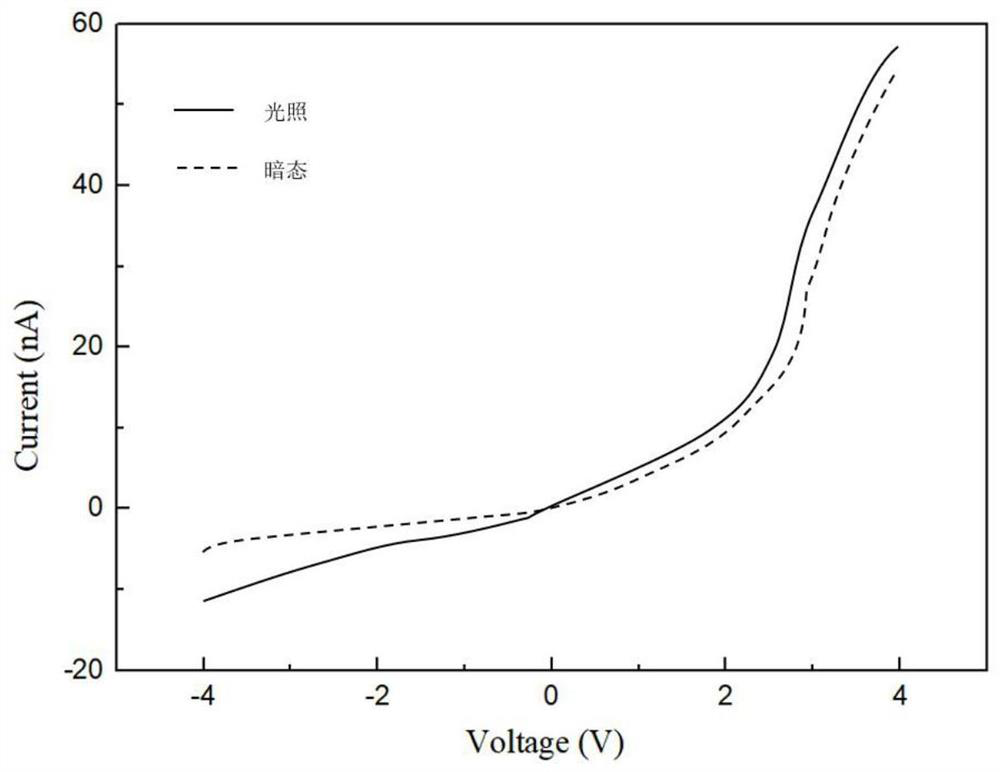

F-beta-Ga2O3/CuGaO2 ultraviolet photoelectric detector and preparation method thereof

An electric detector, -ga2o3 technology, applied in the field of F-β-Ga2O3/CuGaO2 ultraviolet photodetector and its preparation, can solve the problems of slow response speed, low photosensitivity, low responsivity, etc., to promote separation, The effect of increasing the contact area and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

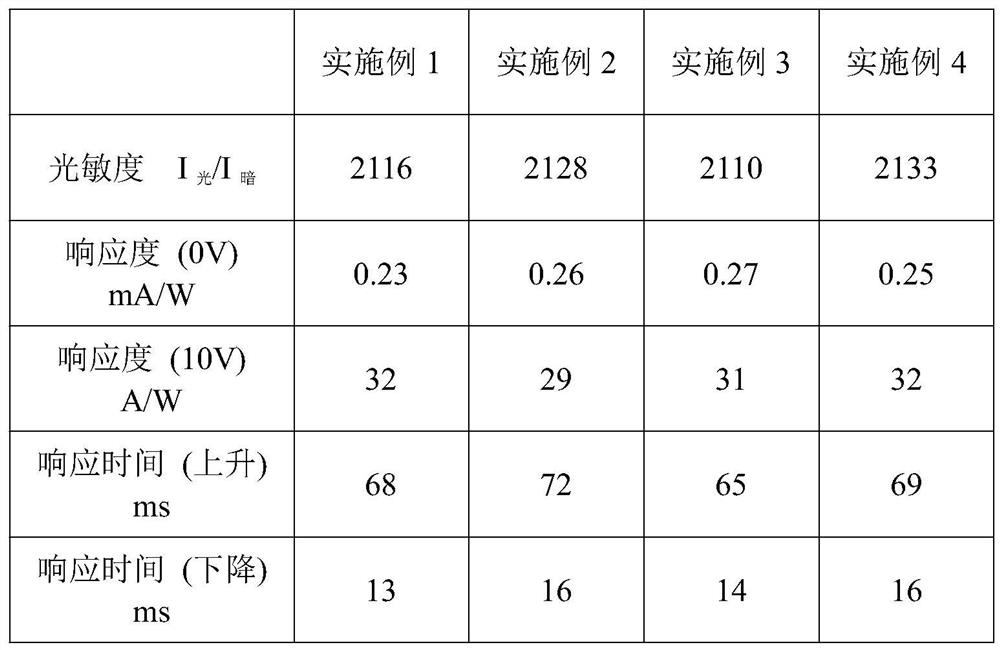

Embodiment 1

[0027]Step 1: Add 3.99g of copper acetate and 5.1g of gallium nitrate to 49.9ml of deionized water, sonicate for 15min at room temperature, slowly drip 63.8ml of NaOH solution into the solution, and stir for 20min in a 60℃ water bath, then Drop 15ml of ethylene glycol solution into the mixed solution and continue to stir at the same temperature for 12 minutes and then let it stand for 1 hour. After standing still, place the solution in the inner lining of the reactor and react for 48 hours at 190°C. Cool naturally to room temperature and dilute with The product was centrifuged and washed with nitric acid until the washing solution was neutral, and then washed with anhydrous ethanol and deionized water alternately 4 times, and then the product was dried in a vacuum drying oven at 65°C to obtain CuGaO2Nanosheets.

[0028]Step 2: Put 3.3g of CuGaO2Nanosheets and 3.69g gallium nitrate were added to 36.9ml deionized water, sonicated for 20min, and then slowly dripped into the NaOH solution ...

Embodiment 2

[0032]Step 1: Add 7g of copper acetate and 7.2g of gallium nitrate to 87.5ml of deionized water, sonicate for 20min at room temperature, slowly drip 84ml of NaOH solution into the solution, and stir in a water bath at 50℃ for 30min, then mix Drop 20ml of ethylene glycol solution into the solution and continue to stir at the same temperature for 13 minutes and then stand for 2 hours. After standing still, place the solution in the inner lining of the reactor and react for 36 hours at 210°C. After cooling to room temperature, use dilute nitric acid. The product was centrifuged and washed until the washing solution was neutral, and then washed with anhydrous ethanol and deionized water alternately for 4 times, and then the product was dried in a vacuum drying oven at 66°C to obtain CuGaO2Nanosheets.

[0033]Step 2: Put 5.78g of CuGaO2Nanosheets and 4.39g gallium nitrate were added to 43.9ml deionized water, sonicated for 25min, and then slowly dripped into NaOH solution at room temperatur...

Embodiment 3

[0037]Step 1: Add 5.24g of copper acetate and 5.76g of gallium nitrate to 65.5ml of deionized water, sonicate for 18min at room temperature, slowly drip 68.2ml of NaOH solution into the solution, and stir for 28min in a 53℃ water bath, then Drop 16ml of ethylene glycol solution into the mixed solution and continue to stir at the same temperature for 10 minutes and then let it stand for 2 hours. After standing still, place the solution in the inner lining of the reactor and react at 200°C for 40 hours. Cool naturally to room temperature and dilute with The product was centrifuged and washed with nitric acid until the washing solution was neutral, and then washed with anhydrous ethanol and deionized water alternately 4 times, and then the product was dried in a vacuum drying oven at 69°C to obtain CuGaO2Nanosheets.

[0038]Step 2: Put 4.33g CuGaO2Nanosheets and 3.46g of gallium nitrate were added to 34.6ml of deionized water, sonicated for 23min, and then slowly dripped into NaOH solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com