Cu/ETS-10 supported SCR catalyst synthesis method

A SCR catalyst and supported technology, which is applied in the synthesis field of supported SCR catalyst Cu/ETS-10, can solve the problems of difficult control of the content and high alkali metal content, and achieve the characteristics of regular micropore structure, simple preparation process and low preparation conditions easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

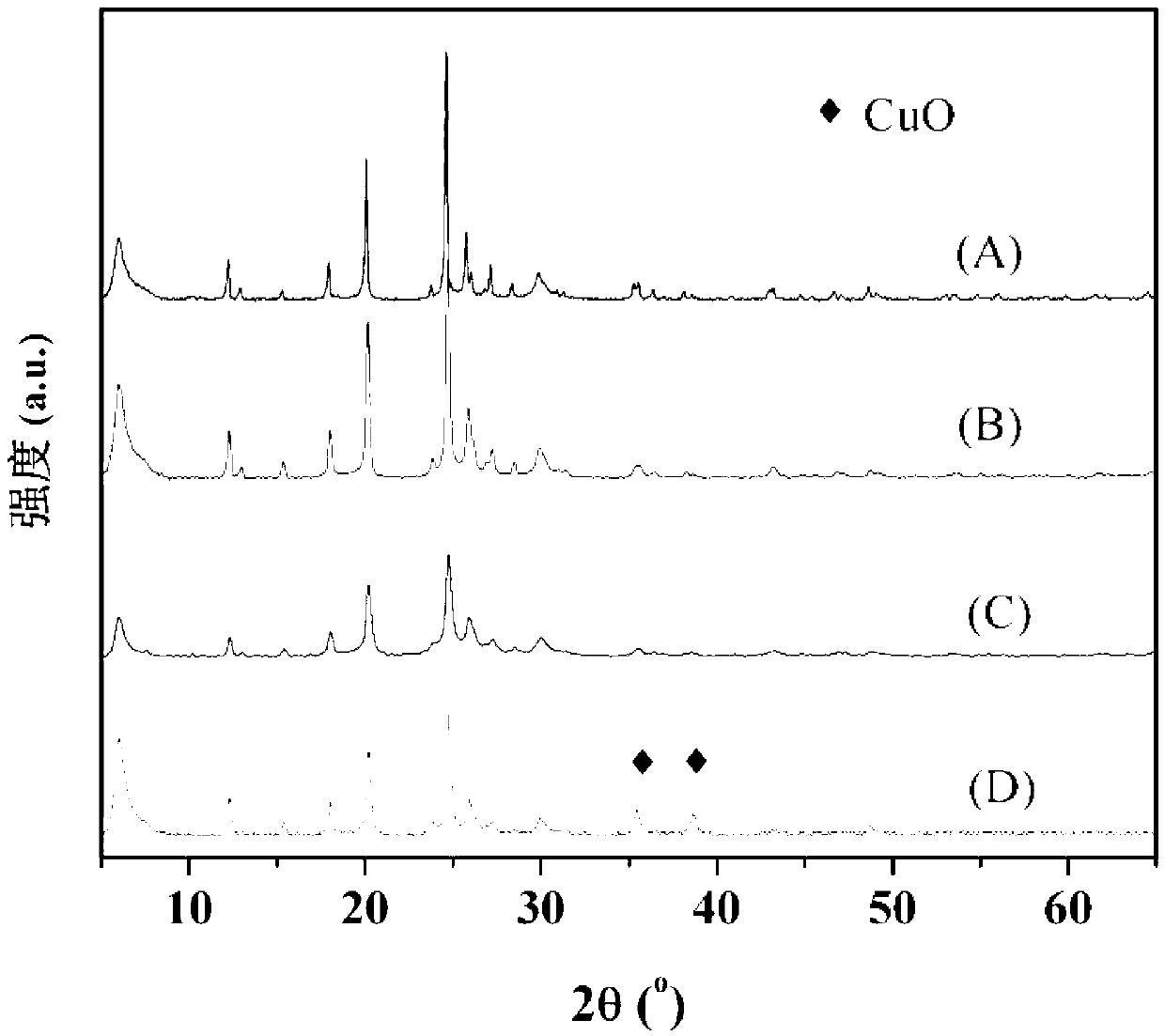

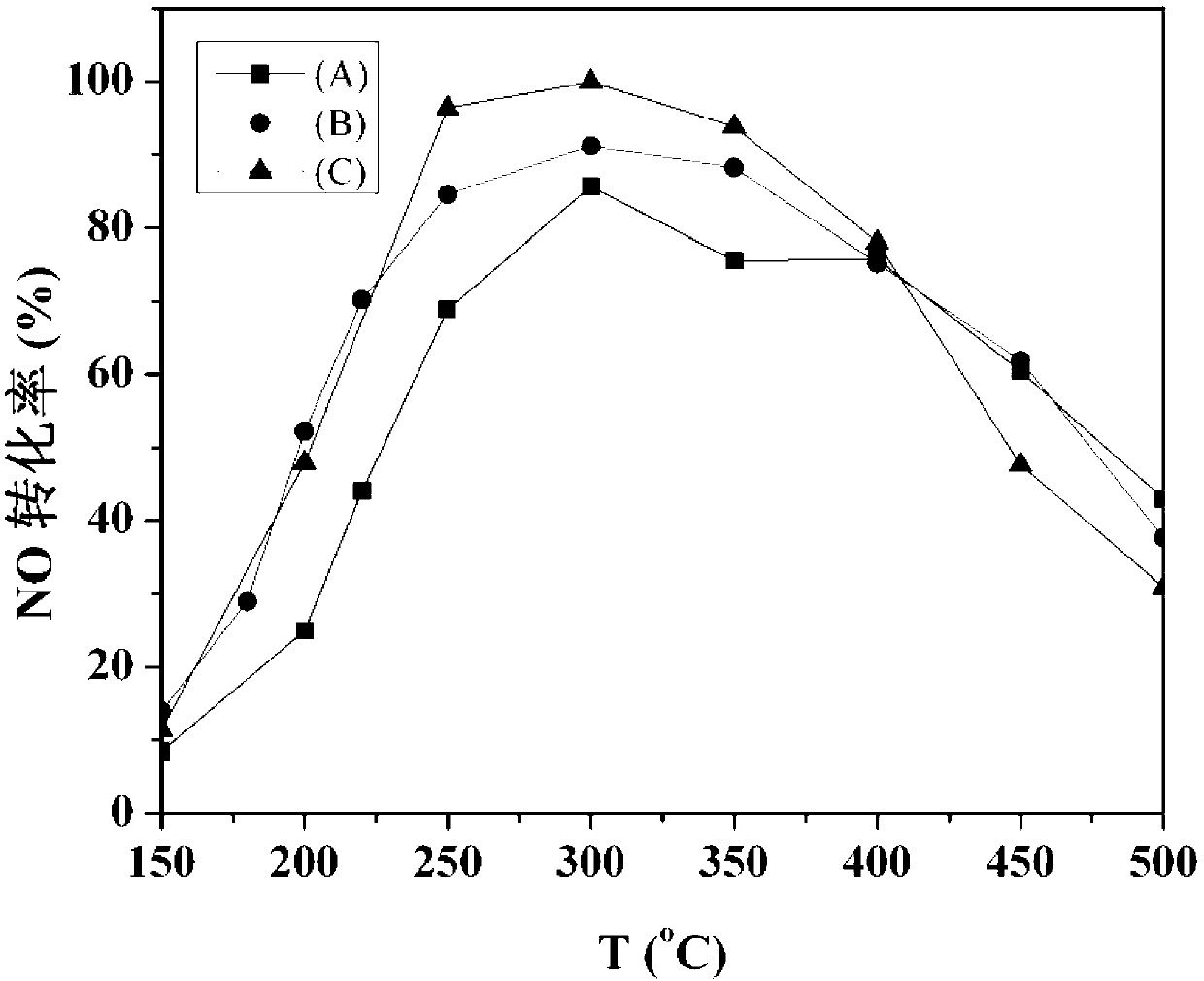

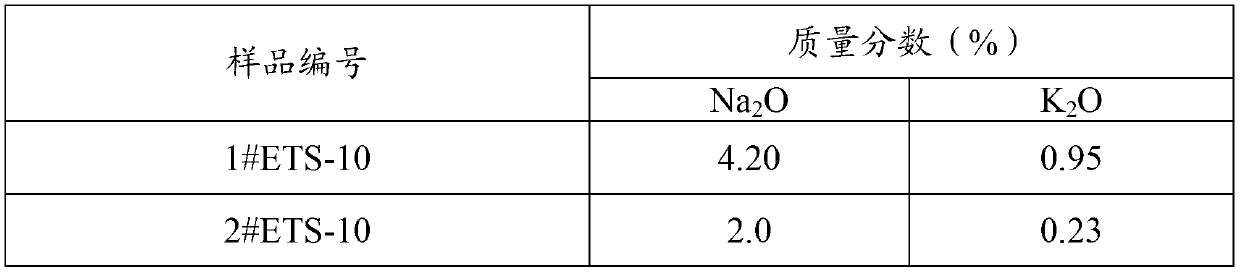

[0021] Dissolve 107 g of ammonium nitrate in 1300 ml of deionized H 2 O, stirred until completely dissolved, then added 20g of ETS-10 powder, and stirred in an oil bath at 85°C for 10h. After standing to cool, suction filter and dry to obtain 1# carrier ETS-10.

[0022] Using copper acetate solution as raw material, by impregnation method, the mass ratio of deionized water: 1# carrier ETS-10 is 5:1, and the solvent is evaporated in a water bath at 70°C to prepare a catalyst loaded with 5.0wt.% Cu / ETS-10. After drying at 120°C for 12 hours and calcining at 500°C for 4 hours, the catalyst prepared by the impregnation method is marked as 1#M, and its Langmuir specific surface is 536m 2 / g.

Embodiment 2

[0024] Dissolve 64.2 g of ammonium nitrate in 780 ml of deionized H 2 O, stir until completely dissolved, add 12g of 1# carrier ETS-10, and stir in an oil bath at 85°C for 10h. After standing to cool, suction filter and dry to obtain 2# carrier ETS-10.

[0025] Using copper acetate solution as raw material, by impregnation method, the mass ratio of deionized water: 2# carrier ETS-10 is 5:1, and the solvent is evaporated in a water bath at 70°C to prepare a catalyst loaded with 5.0wt.% Cu / ETS-10. After drying at 120°C for 12 hours and calcination at 500°C for 4 hours, the catalyst prepared by the impregnation method was marked as 2#M, and its Langmuir specific surface was 512m 2 / g.

Embodiment 3

[0027] Dissolve 42.8 g of ammonium nitrate in 520 ml of deionized H 2 O, stirred until completely dissolved, then added 8g of 2# carrier ETS-10, and stirred in an oil bath at 85°C for 10h. After standing to cool, suction filter and dry to obtain 3# carrier ETS-10.

[0028]Using copper acetate solution as raw material, the mass ratio of deionized water: 3# carrier ETS-10 is 5:1, and the solvent is evaporated under the condition of 70 ℃ water bath by dipping method to prepare the supported 5.0wt.% Cu / ETS-10 catalyst, After drying at 120℃ for 12h and calcining at 500℃ for 4h, the catalyst prepared by impregnation method was marked as 3#M, and its Langmuir specific surface was 514m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com