A kind of copper-doped red light perovskite quantum dot and preparation method thereof

A technology of perovskite and quantum dots, applied in chemical instruments and methods, luminescent materials, nano-optics, etc., can solve the problem of affecting device efficiency, poor stability of red perovskite quantum dots, blue shift of fluorescence emission wavelength, etc. problem, to achieve high fluorescence quantum efficiency, high efficiency, stability, solution processability, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In some embodiments, the preparation method specifically includes the following steps:

[0039] (1) Copper salt and oleic acid are mixed and dissolved to obtain a copper precursor solution;

[0040] (2) mixing and heating a cesium salt or a formamidine salt with a mixed solution of octadecene and oleic acid to obtain a cesium or formamidine precursor solution;

[0041](3) under the protection of an inert gas, the mixture of the copper precursor solution, lead iodide and lead bromide obtained in step (1) is mixed with an octadecene solution containing an organic acid and an organic amine, heated and dissolved to obtain a mixed solution, and then Mix the mixed solution with the cesium or formamidine precursor solution obtained in step (2) at 140-180° C. After the reaction, place the reactor in an ice-water bath to stop the reaction to obtain a mixed system of reaction products;

[0042] (4) Mix and centrifuge the reaction product mixture system obtained in step (3) with ...

Embodiment 1

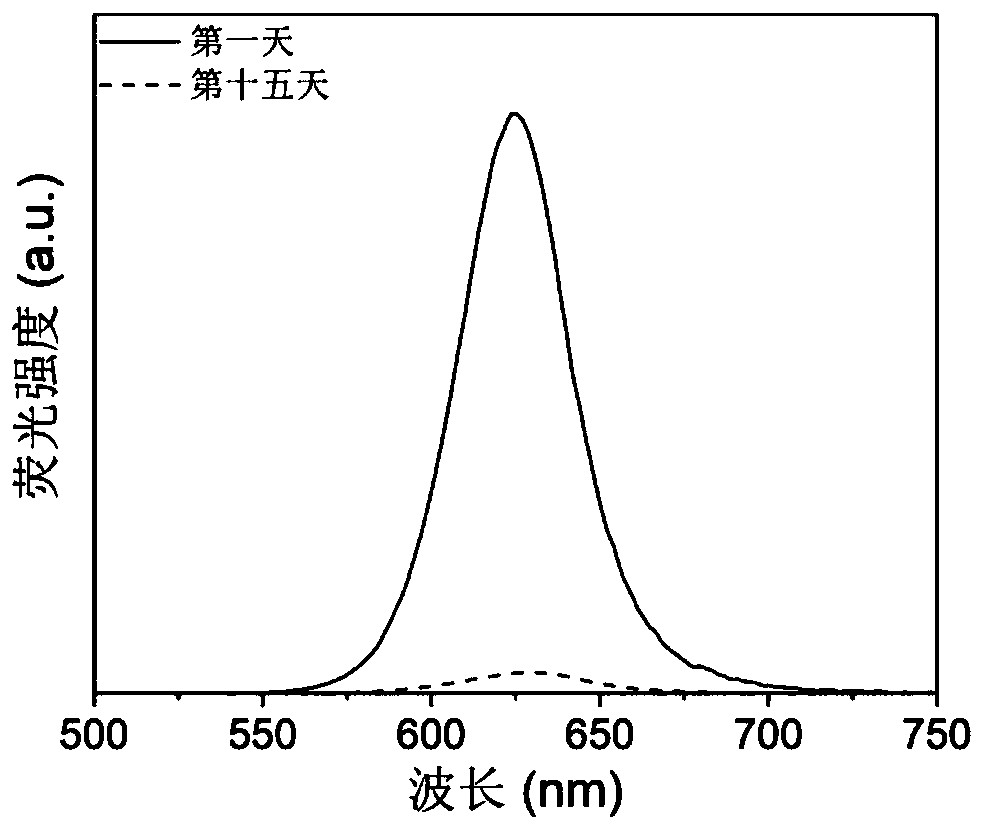

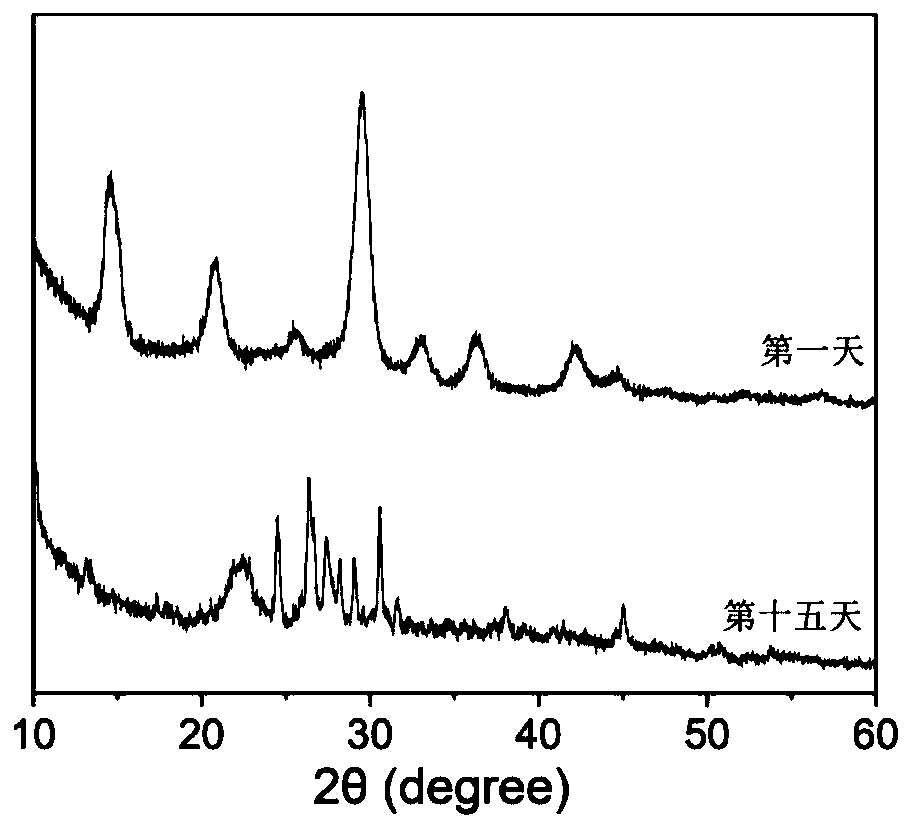

[0062] A red light perovskite quantum dot colloid solution, the quantum dot material structure is composed of CsPb 0.9 Cu 0.1 BrI 2 , the maximum fluorescence emission wavelength is 633nm, the material is cubic phase, and the particle diameter is 8-15 nanometers.

[0063] Prepared as follows:

[0064] Dissolve 0.0341g of copper acetate in 1mL of oleic acid and heat to 90°C until the copper acetate is completely dissolved to obtain a dark green copper oleate precursor. Add 0.1682g of cesium carbonate, 8mL of octadecene, and 0.5mL of oleic acid into a 100mL flask, and heat to 120°C with nitrogen gas until the cesium carbonate is completely dissolved. 0.0230g PbBr 2 with 0.0578gPbI 2 , add 5mL octadecene, 0.1mL copper oleate precursor, 0.4mL oleic acid, 0.5mL oleylamine into a 100ml flask, heat to 120°C and vacuum dry for 1 hour, blow nitrogen, raise the temperature to 150°C, inject the The prepared cesium oleate precursor was 0.4 mL, and immediately cooled to room temperat...

Embodiment 2

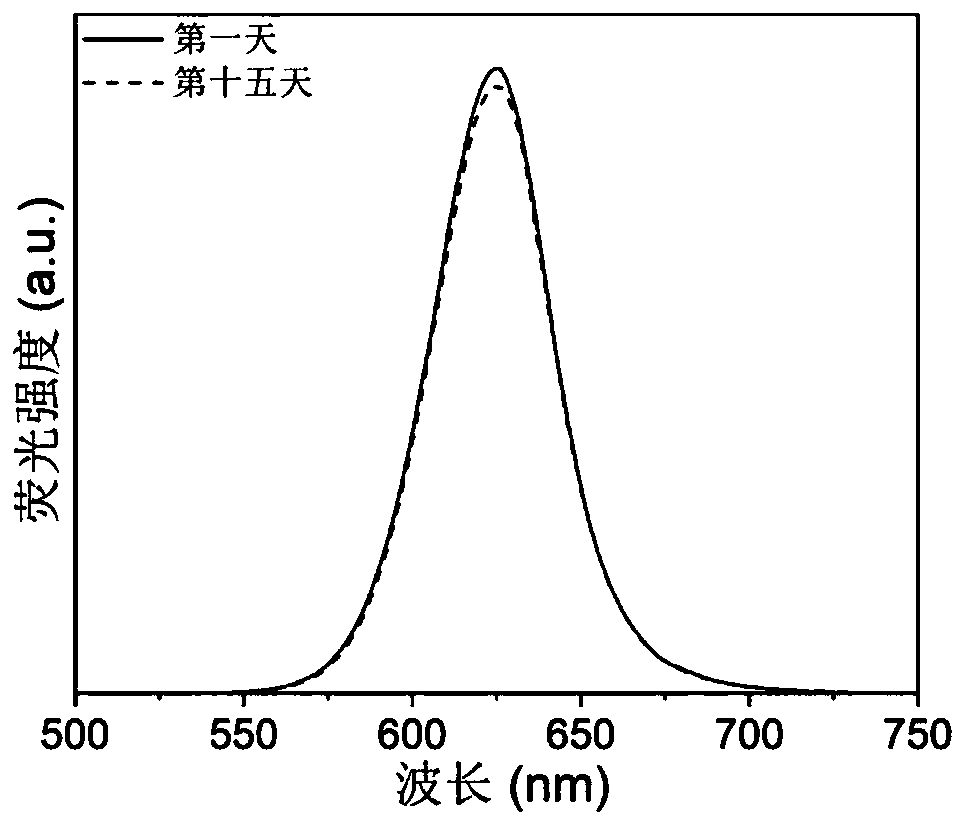

[0067] A red light perovskite quantum dot colloid solution, the quantum dot material structure is composed of CsPb 0.8 Cu 0.2 BrI 2 , the maximum fluorescence emission wavelength is 631nm, the material is cubic phase, and the particle size is 8-15nm.

[0068] Prepared as follows:

[0069] Dissolve 0.0341g of copper acetate in 1mL of oleic acid and heat to 90°C until the copper acetate is completely dissolved to obtain a dark green copper oleate precursor. Add 0.1682g of cesium carbonate, 8mL of octadecene, and 0.5mL of oleic acid into a 100mL flask, and heat to 120°C with nitrogen gas until the cesium carbonate is completely dissolved. 0.0230g PbBr 2 with 0.0578gPbI 2 , add 5mL octadecene, 0.2mL copper oleate precursor, 0.3mL oleic acid, 0.5mL oleylamine into a 100ml flask, heat to 120°C and vacuum dry for 1 hour, blow nitrogen, raise the temperature to 150°C, inject the pre- The prepared cesium oleate precursor was 0.4 mL, and immediately cooled to room temperature with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com