Method for preparing integral type seamless metal fiber perforated pipe and tangling device

A metal fiber, integral technology, applied in the field of material processing and manufacturing, can solve the problems of affecting work efficiency, small thickness of fiber perforated plate, and restricting the application of sound absorption of materials, etc., to achieve the effect of convenient realization, easy process and saving welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of monolithic seamless FeCrAl fiber porous muffler pipe:

[0027] Step 1, machining the unsintered FeCrAl fiber blank mat with a wire diameter of 6 μm, and smoothing the surface;

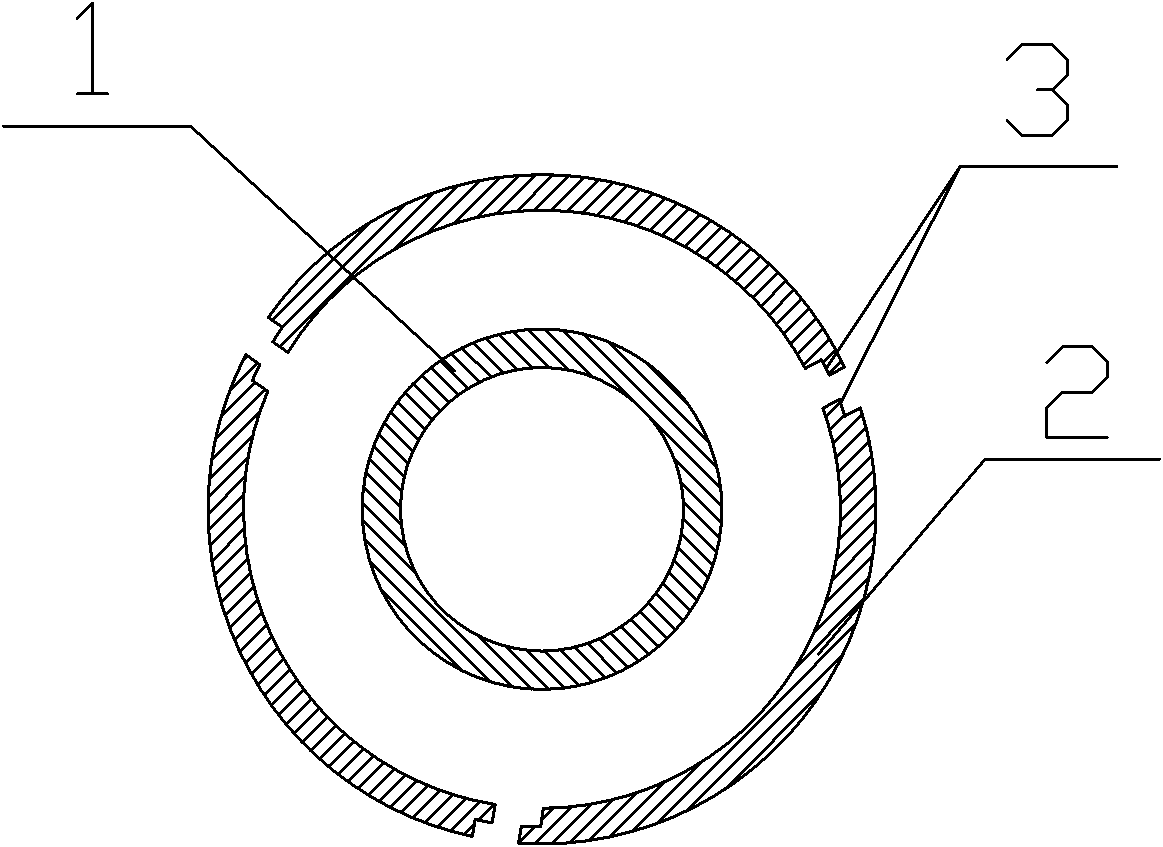

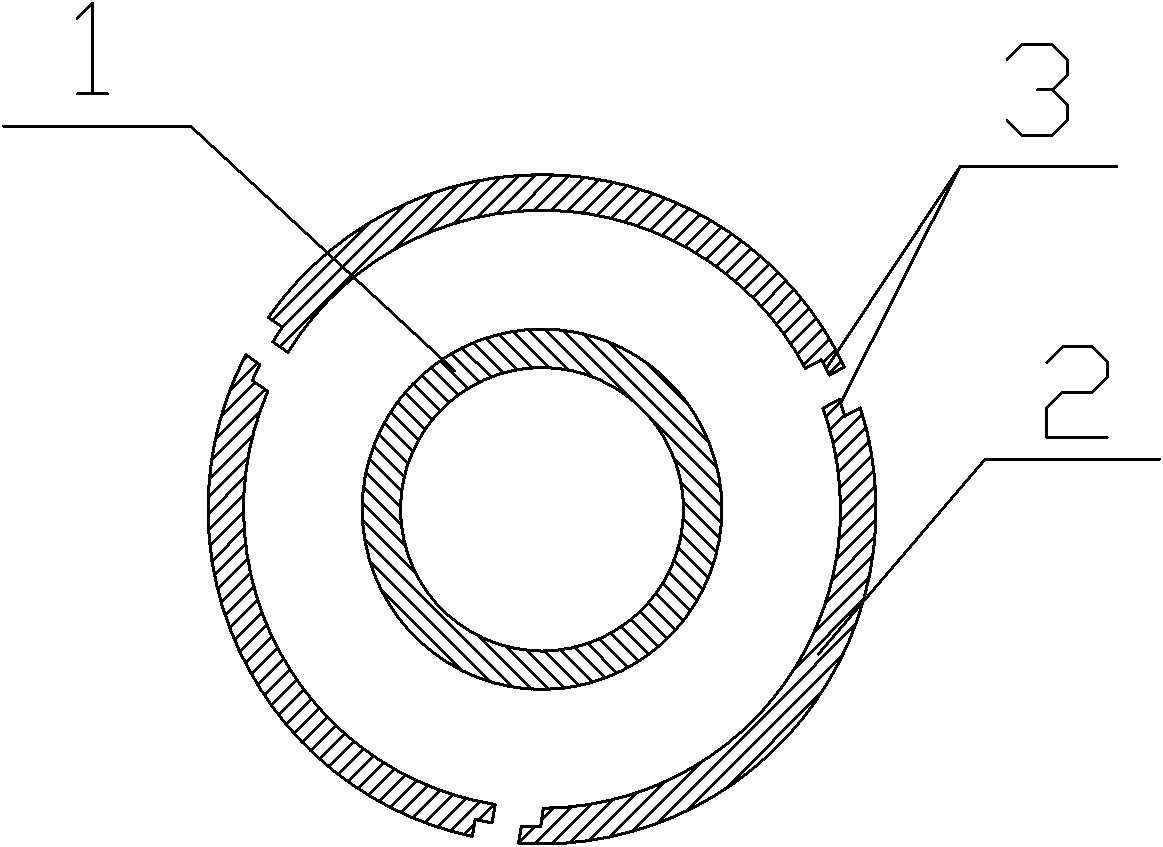

[0028] Step 2. Oxidize the three-lobe split pipe mold with a length of 100mm at a temperature of 1100°C for 3 hours; the inner mold support body 1 of the three-lobe split pipe mold has an outer diameter of 79mm and a pipe wall thickness of 2mm Al 2 o 3 Tube, three-lobed split-type outer mold 2 is a three-lobed split-type FeCrAl tube with an inner diameter of 140 mm and a tube wall thickness of 2 mm;

[0029] Step 3, entangle the FeCrAl fiber blank felt after the flattening treatment on the inner mold support body 1 of the oxidized three-lobed split pipe mold by rolling forming, the entanglement thickness is 30mm, and then Pack into the three-lobe split-type outer mold 2 and close;

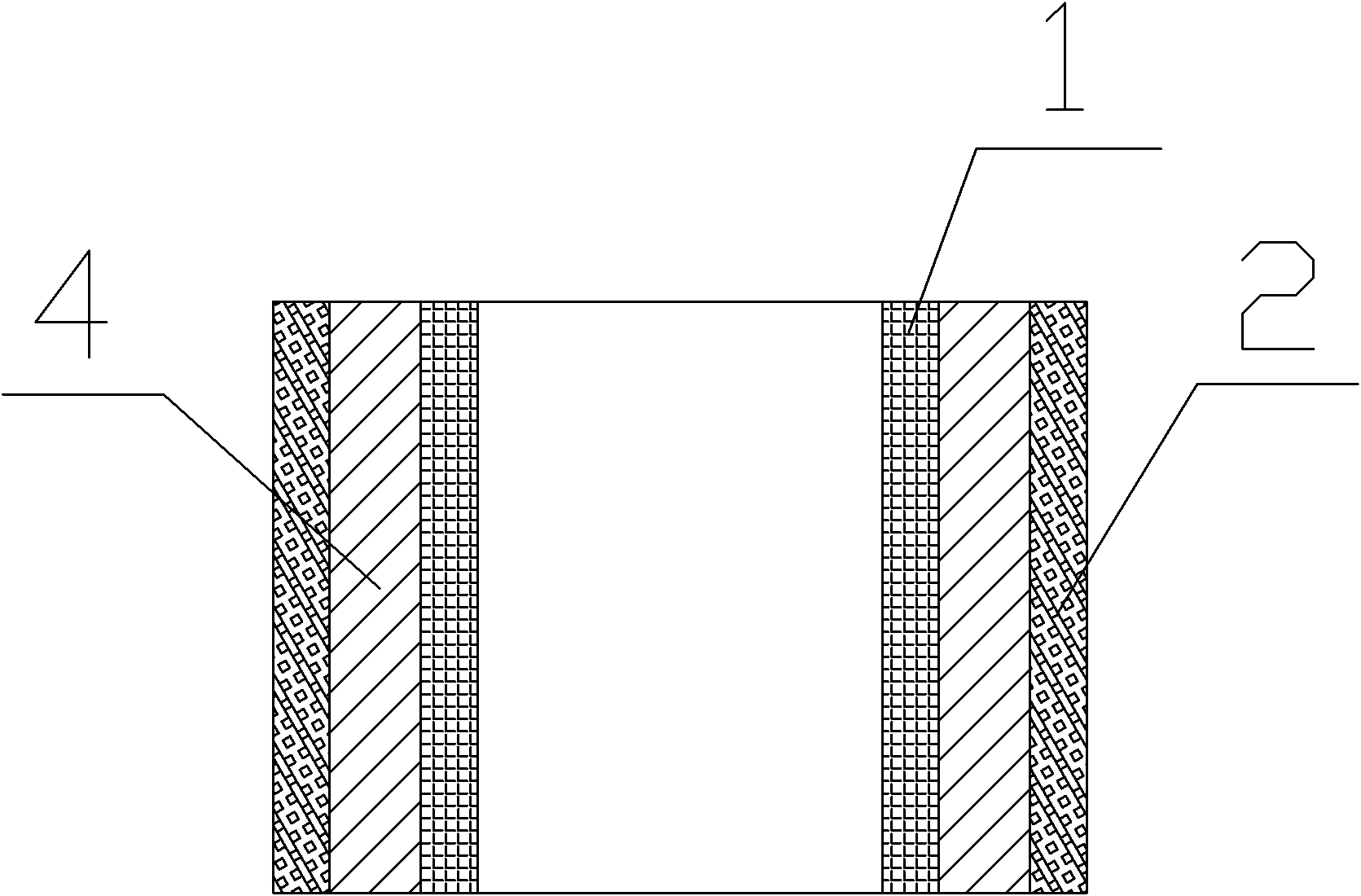

[0030] Step 4. Fasten the closed three-lobed split pipe mold with metal fiber blank felt 4 (FeC...

Embodiment 2

[0032] Preparation of monolithic seamless copper fiber porous heat transfer tube:

[0033] The preparation method of this example is the same as that of Example 1. The difference is that the metal fiber blank felt is copper fiber blank felt, and an integral seamless copper fiber porous heat transfer tube is prepared. The integral seamless copper fiber porous heat transfer tube The heat pipe can be used for heat recovery and reuse of high temperature water or gas.

Embodiment 3

[0035] Preparation of integral seamless stainless steel fiber porous filter tube:

[0036] The preparation method of this example is the same as that of Example 1, and the difference is that the metal fiber blank felt is stainless steel fiber blank felt, and an integral seamless stainless steel fiber porous filter tube is prepared, and the integral seamless stainless steel fiber porous filter tube is It can be used as a gas-solid or gas-liquid separation element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com