Tooling clamp for manufacturing output bracket of automobile speed changer

A technology for automobile transmission and tooling fixture is applied in the field of tooling and fixture, which can solve the problems of increasing processing complexity, increasing processing cost, difficulty in manual removal, etc., and achieving the effects of simple structure, convenient processing and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

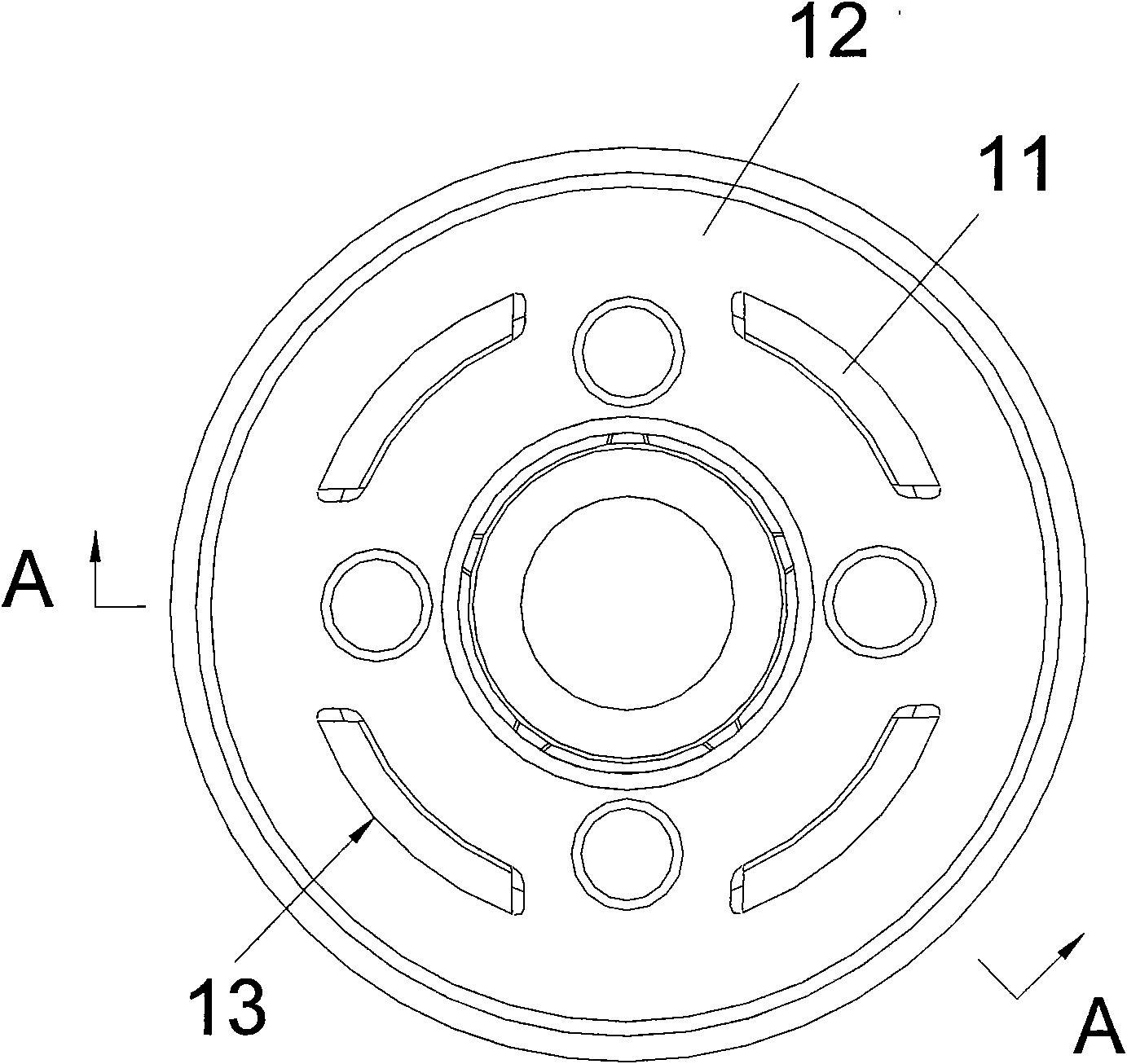

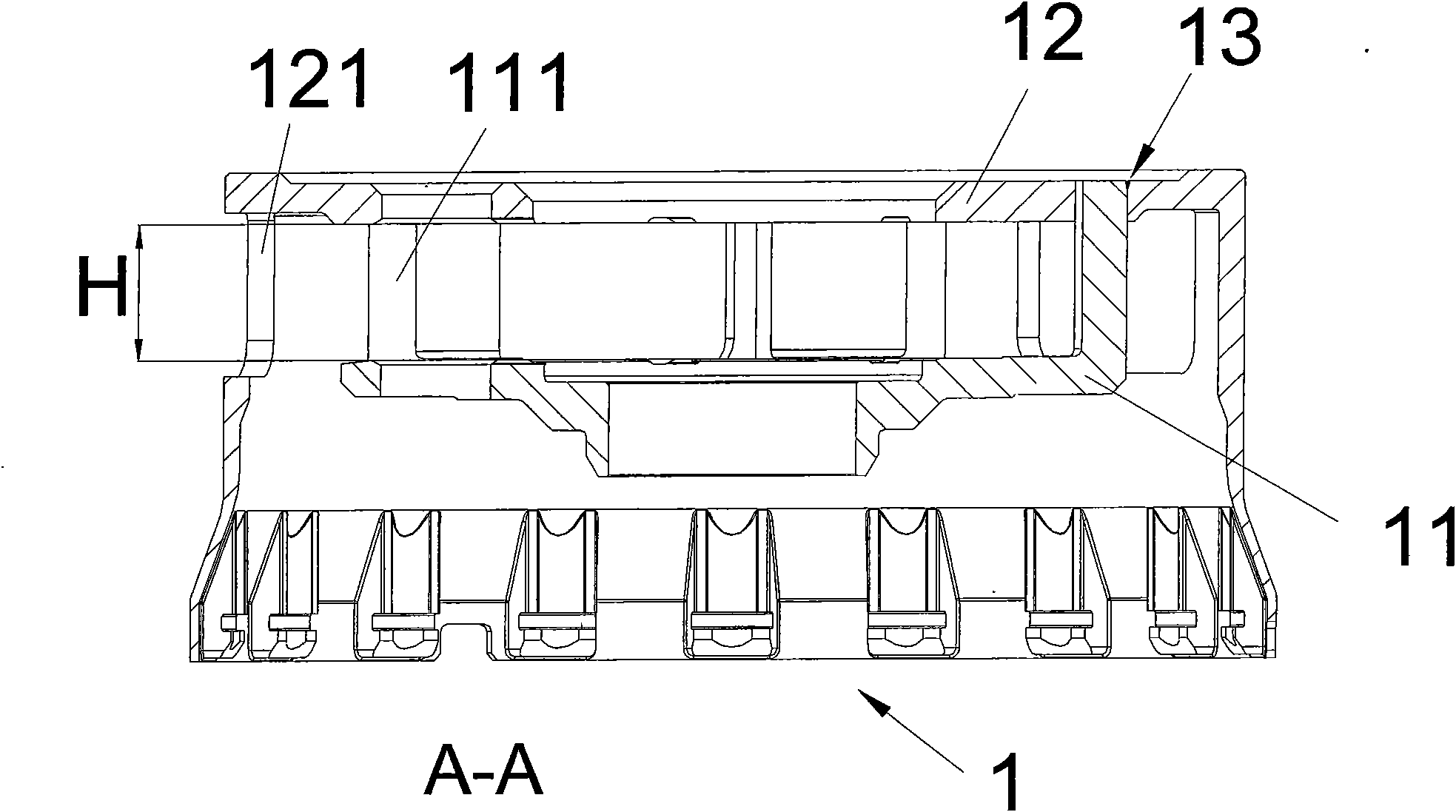

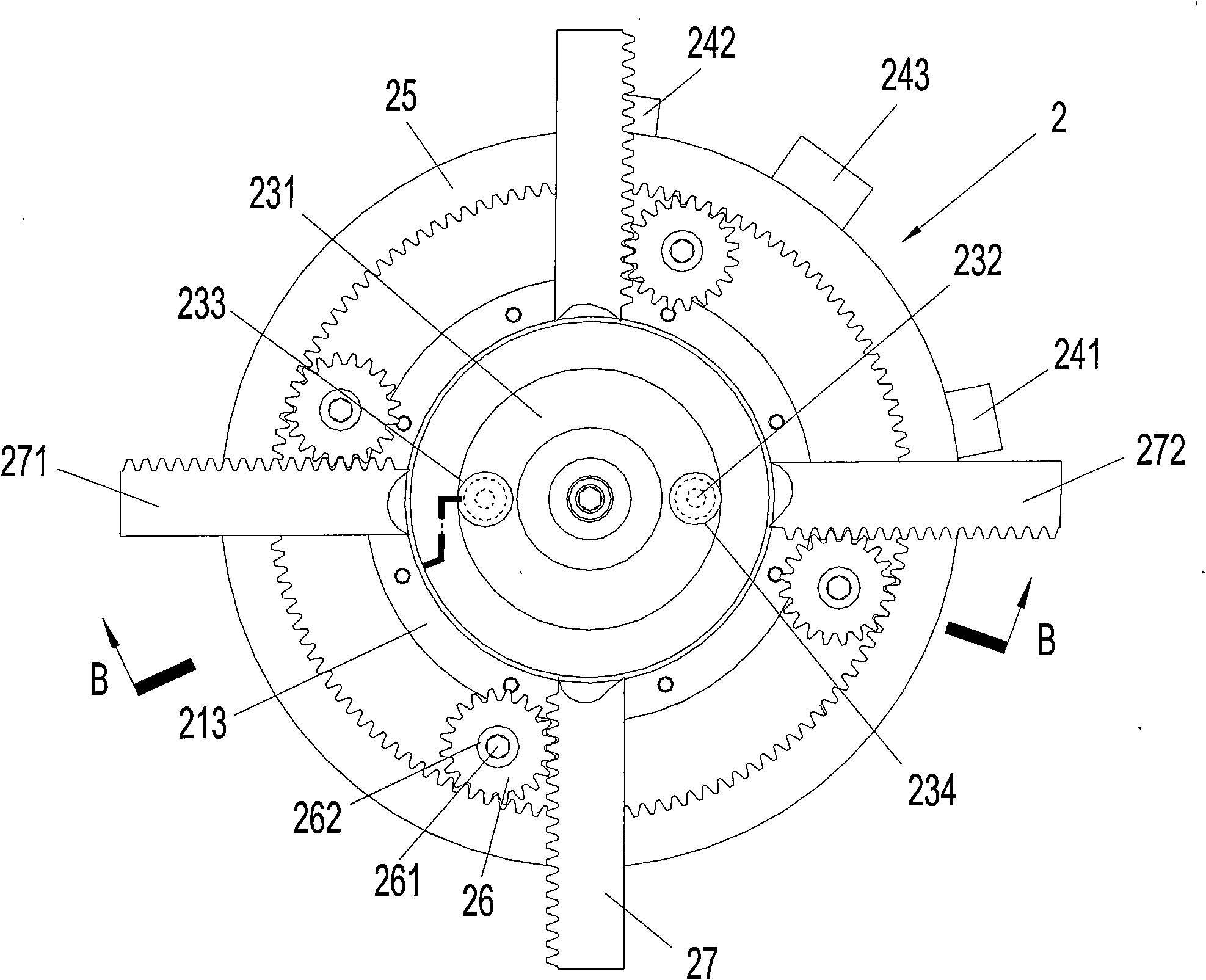

[0022] see image 3 and Figure 4 , the present invention is used to manufacture the tooling fixture of automobile transmission output bracket, and this tooling fixture 2 comprises a base 21, a ring gear 25, a gear set, a cover plate 22, a rack set, a parts positioning device 23 and a Ring gear limiting device 24;

[0023] In the above-mentioned jig used to manufacture the output bracket of the automobile transmission, the top surface of the base 211 is provided with three progressively shrinking steps, which are respectively the first step 215, the second step 212 and the third step 213. A recessed hole 214 is sunken at the center of the three steps 213;

[0024] In the above-mentioned fixture for manufacturing the output bracket of the automobile transmission, the inner wall surface of the ring gear 25 is provided with straight tooth lines, and the lower part of the inner wall surface of the ring gear 25 is provided with a notch 251, and the notch 251 is arranged on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com