Efficient hot-air engine

A hot gas engine and engine technology, applied in the field of thermal energy and power, can solve the problems of limited heating and cooling time, complex mechanism, etc., and achieve the effects of easy combustion control, improved heat transfer load and efficiency, good combustion efficiency and exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

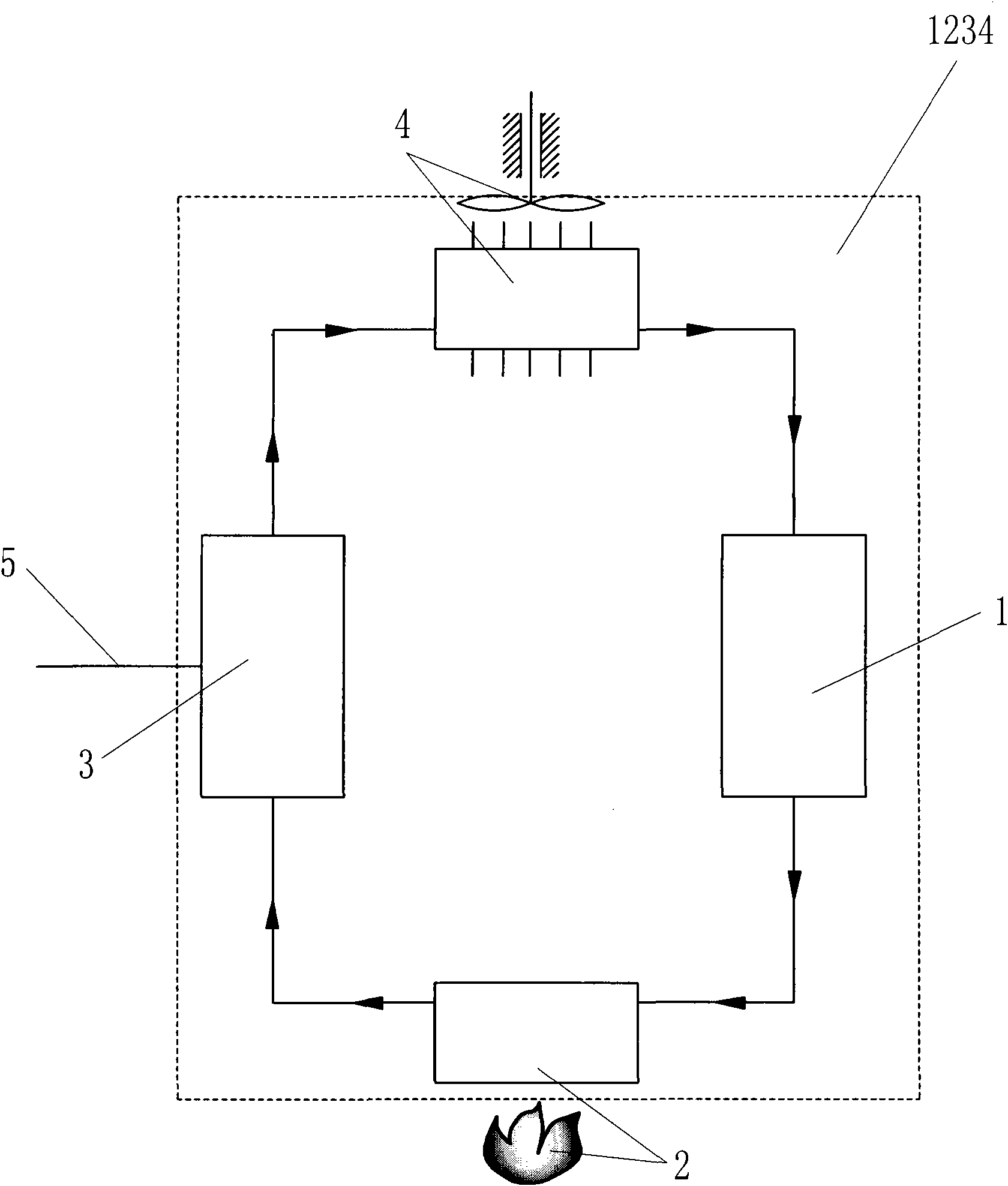

[0050] Such as figure 1 The high-efficiency hot gas engine shown comprises a compressor 1, a heater 2, an explosive discharge engine 3 and a cooler 4, and gas working medium inlets and The gas working medium outlet, the gas working medium outlet of the compressor 1 is connected with the gas working medium inlet of the heater 2, the gas working medium outlet of the heater 2 is connected with the gas working medium inlet of the explosive discharge engine 3, and the gas working medium of the explosive discharge engine 3 is connected. The working medium outlet communicates with the gas working medium inlet of the cooler 4, and the gas working medium outlet of the cooler 4 communicates with the gas working medium inlet of the compressor 1, so that the connection forms a single power unit section closing channel 1234, which is closed at the single power unit section The channel 1234 is filled with gas working medium, the explosive discharge engine 3 outputs power to the compressor ...

Embodiment 2

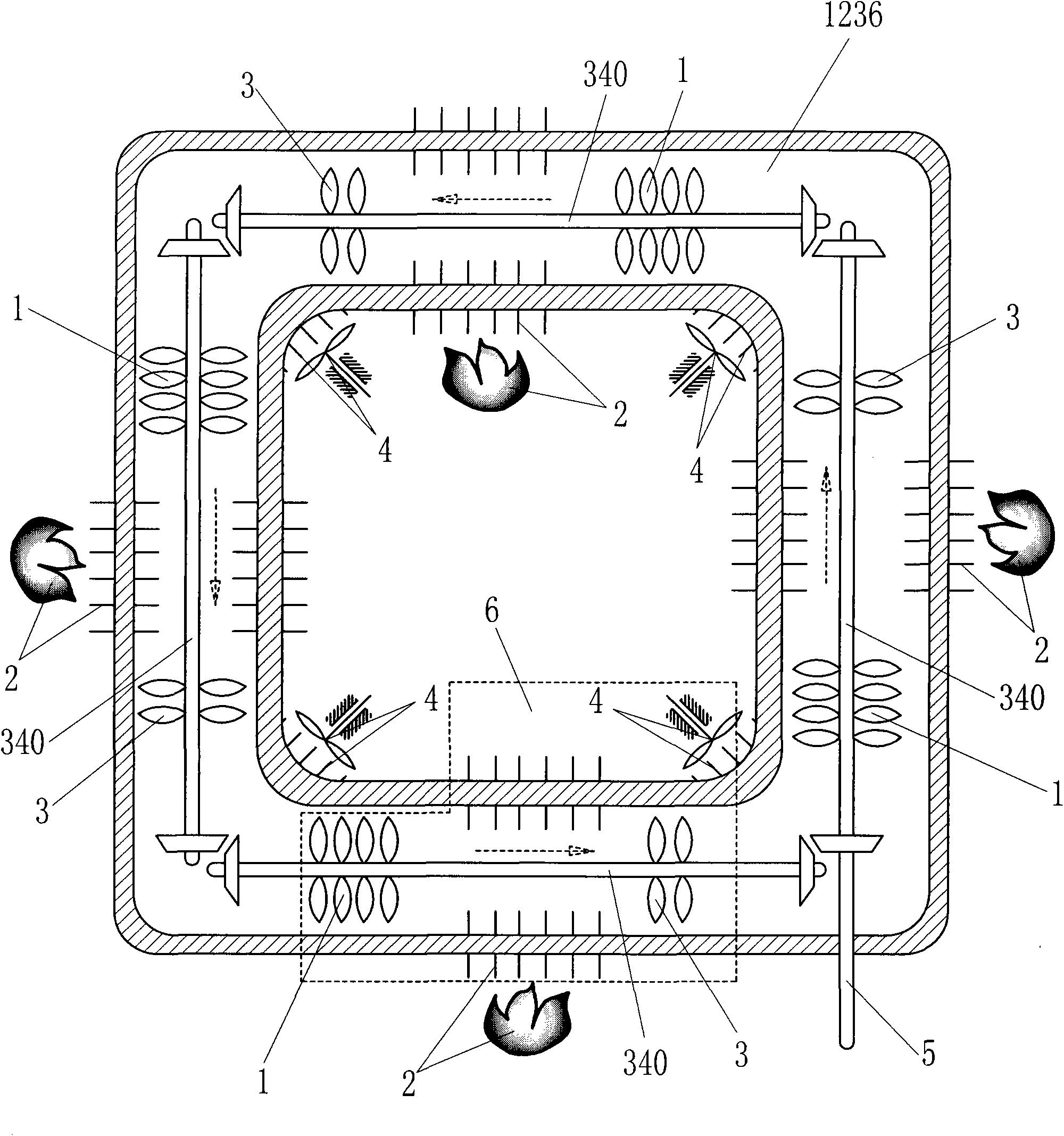

[0052] Such as figure 2 Shown high-efficiency hot gas engine, its difference with embodiment 1 is: gas working medium inlet and gas working medium outlet are set respectively on compressor 1, heater 2, explosion exhaust engine 3 and cooler 4, and the gas working medium outlet of compressor 1 The gas working medium outlet is communicated with the gas working medium inlet of the heater 2, the gas working medium outlet of the heater 2 is communicated with the gas working medium inlet of the explosive discharge engine 3, and the gas working medium outlet of the explosive discharge engine 3 is connected with the gas working medium of the cooler 4. The inlets of the working fluid are connected, so that they form a power unit section 6, n compressors 1, n heaters 2, n explosive discharge engines 3 and n coolers 4 form n power unit sections 6, n=4, The n power unit sections 6 are connected in series, and then the gas working medium outlet of the cooler 4 at one end is connected with ...

Embodiment 3

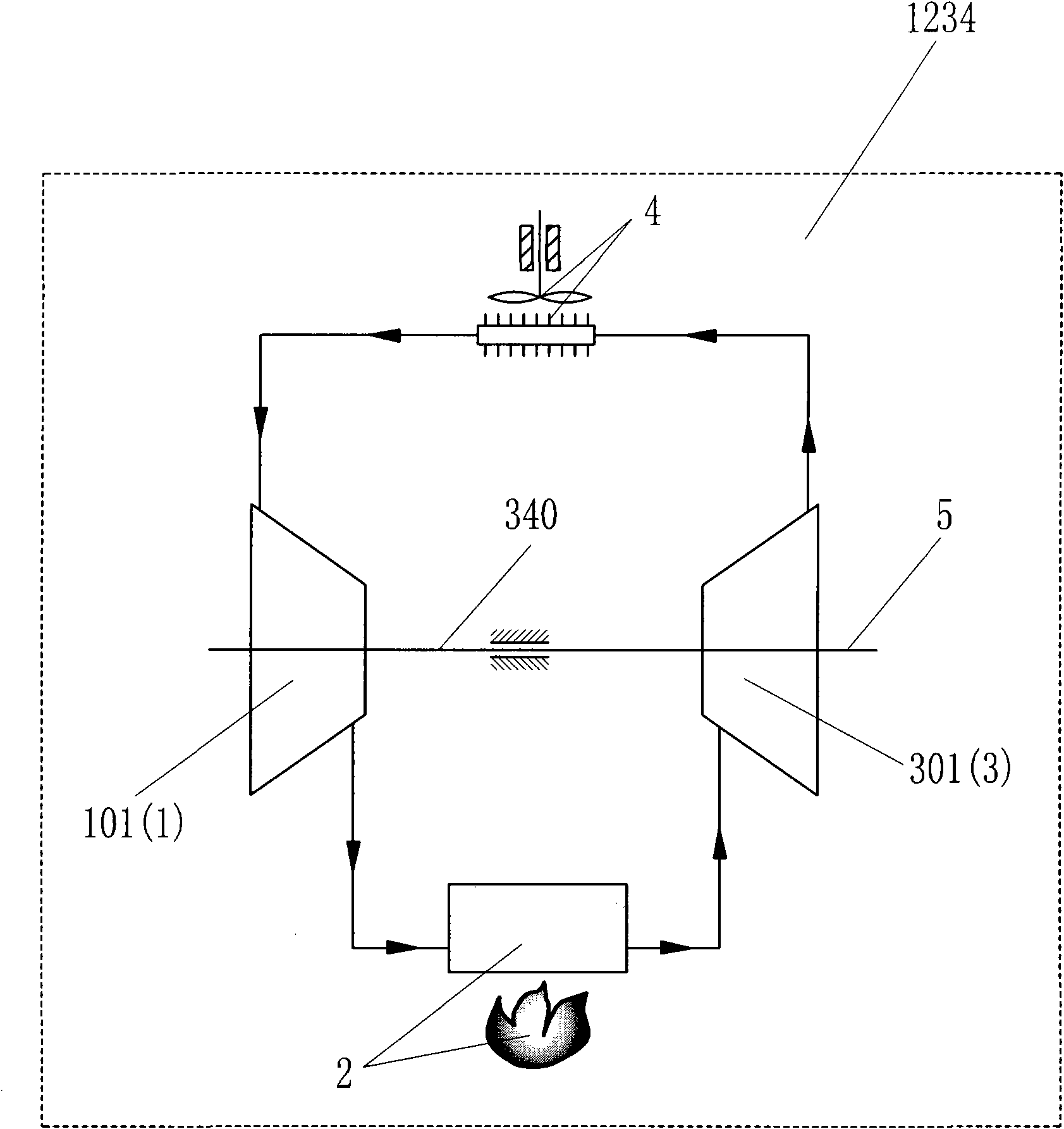

[0054] Such as image 3 The difference between the high-efficiency hot gas engine shown and Embodiment 1 is that the compressor 1 is set as an impeller compressor 101 , and the explosive exhaust engine 3 is set as a power impeller 301 . The purpose of such setting is to make full use of the advantages of high rotational speed, small volume and large flow rate of the impeller compressor 101 and the power impeller 301 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com