Method and device for drying plant fibers

A plant fiber filament and drying device technology, applied in the direction of drying gas arrangement, drying solid materials, drying chamber/container, etc., can solve the problems of poor drying effect, increased production cost, heat waste, etc., and achieve good drying effect and low heat loss Small, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

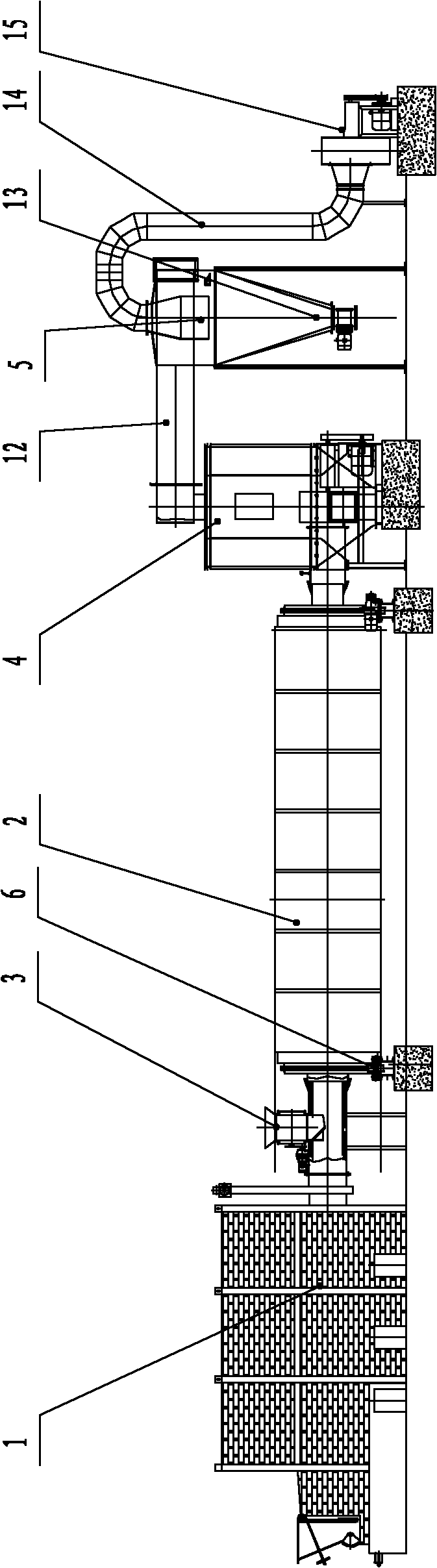

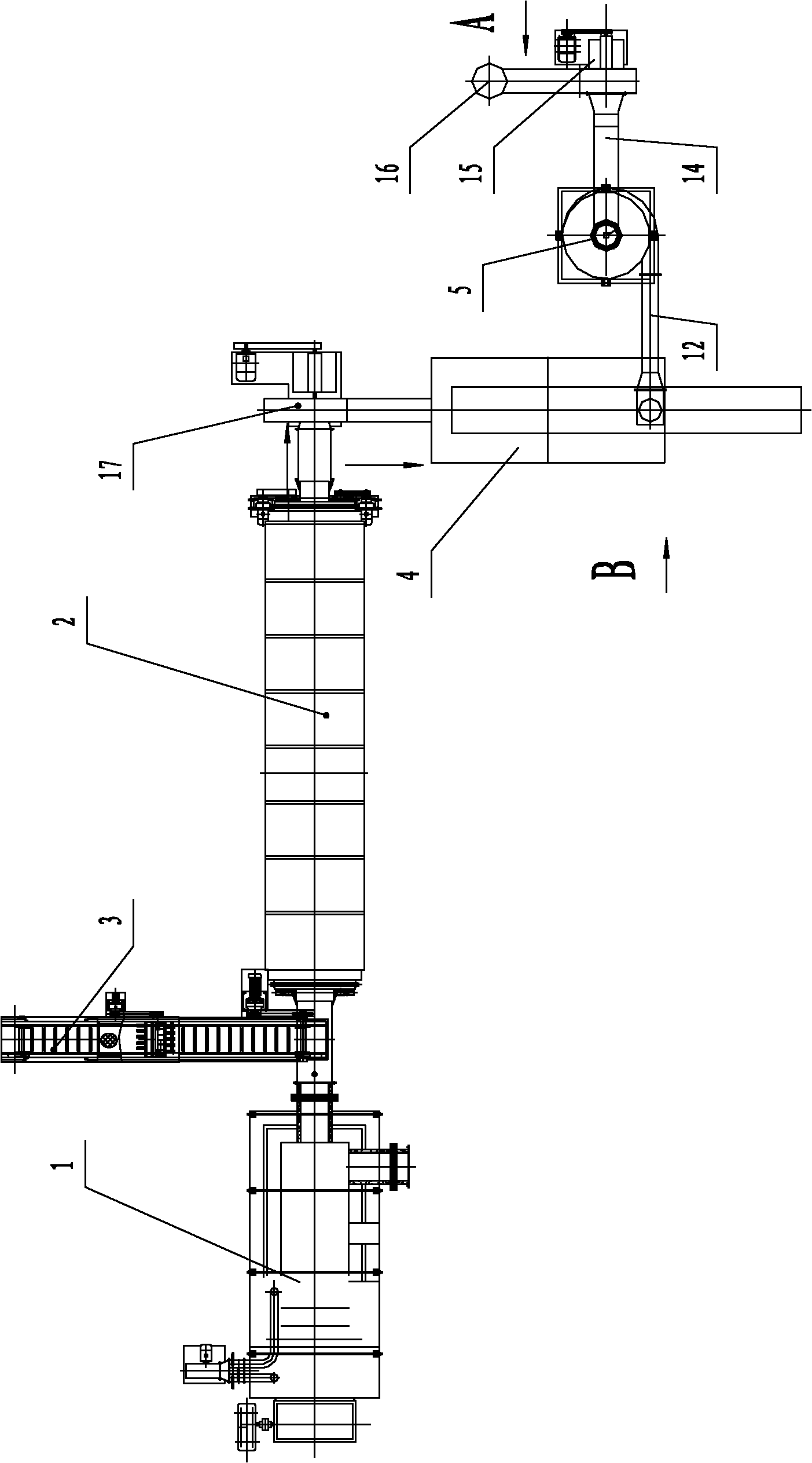

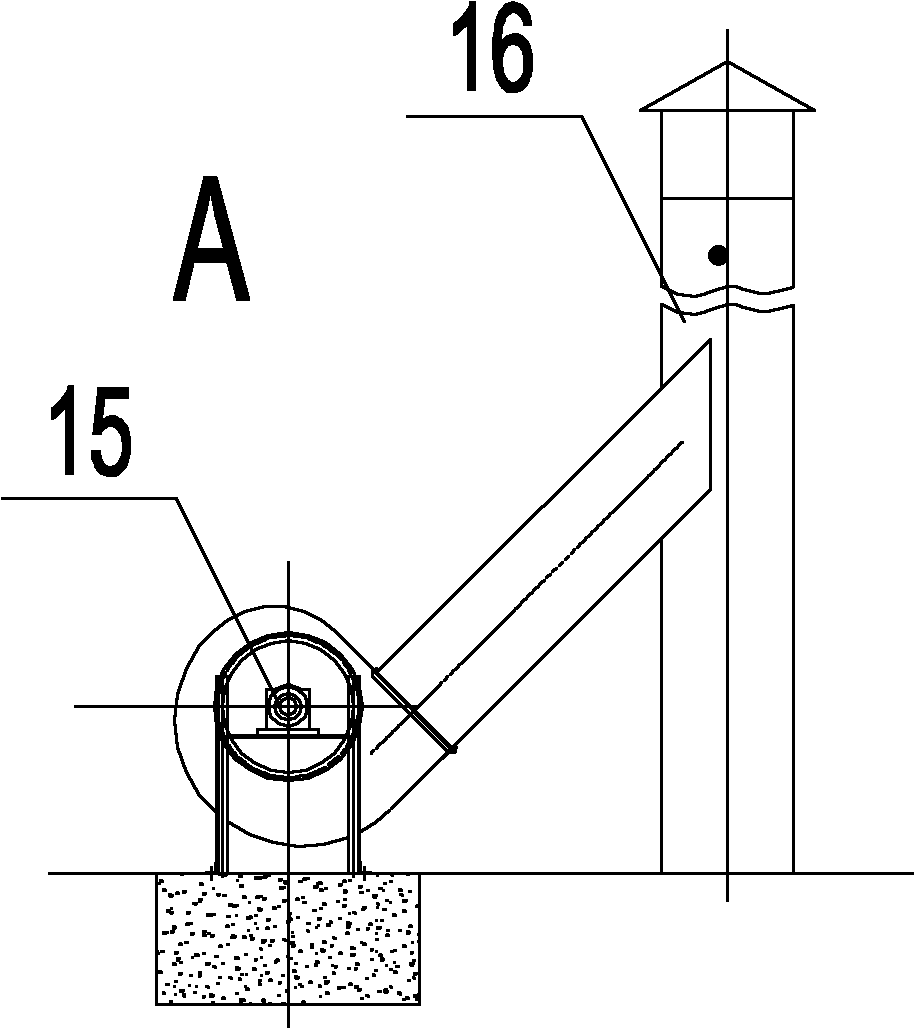

[0022] Example: such as Figure 1-4 As shown, the plant fiber drying device is equipped with a hot blast stove 1, the air outlet of the hot blast stove 1 is connected to the drying drum 2, the feeding machine 3 is connected to the drying drum 2, and the silo 4 is connected to the outlet of the drying drum 2, and in the hopper 4 Connect the dust collector 5. The hot blast stove 1 can adopt biological pellet fuel, coal, water gas and electricity as the heat source, and it is better to adopt biological pellet fuel through comprehensive consideration of aspects such as cost and environment.

[0023] The bottom of the drying drum 2 is connected with a transmission motor 6 to rotate the drying drum 2 .

[0024] In order to improve the drying effect, the first sleeve 7 and the second sleeve 8 are installed inside the drying drum 2, and the inside of the drying drum 2 is divided into a zigzag circuit, which increases the drying process and time of the plant fiber filaments and saves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com