Novel low-temperature flame-retardant electrolyte

A technology of electrolyte and non-aqueous electrolyte, which is applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems of unsatisfactory flame retardant effects, and achieve the effects of widening the low-temperature service temperature, high ion conductivity, and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

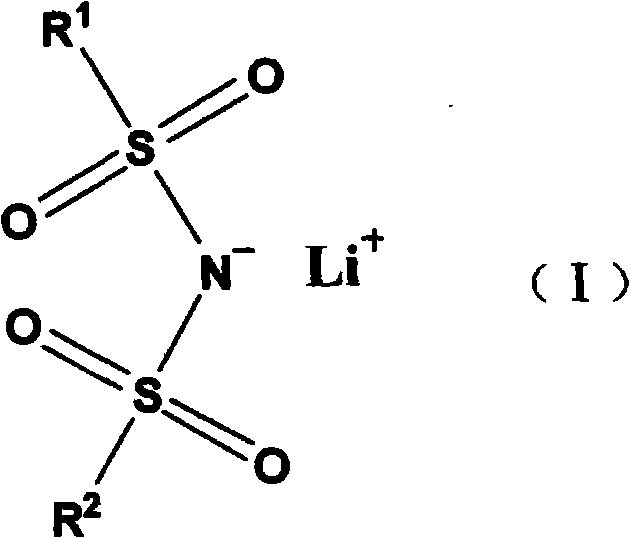

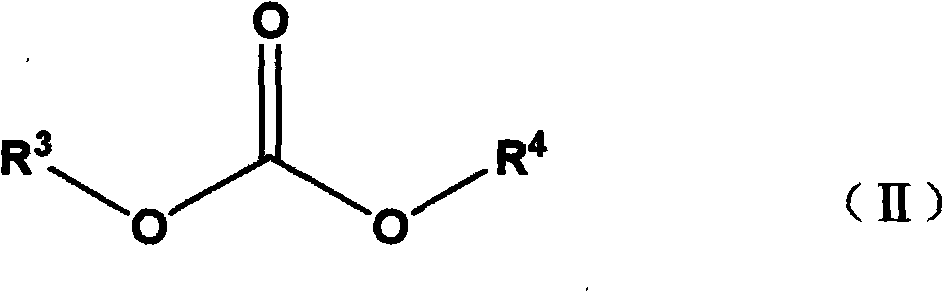

[0029] Electrolyte preparation: dry lithium bis(fluorosulfonyl)imide (Li[FSI]) in vacuum, dry battery-grade organic solvent ethyl methyl carbonate (EMC) and put it in a vacuum glove box (water content is less than 1ppm). Weigh 14.018g Li[FSI] in a beaker, then weigh 3.798g LiPF6 and add it to the beaker, and slowly add it to 100ml of EMC solvent several times under cooling condition with magnetic stirring to prepare an electrolytic solution with a molar concentration of 1.0M Liquid, sealed and stored for later use.

[0030] Conductivity measurement: Add the above electrolyte solution dropwise to a glass conductivity cell with platinum electrodes at both ends, use GDW6005 high and low temperature test chamber to control the temperature, measure impedance spectrum (5Hz-13MHz) with HP4192 impedance spectrometer, and obtain the temperature range Conductivity from -60°C to 60°C. The conductivity measured at -60°C is 0.6mS / cm, the conductivity at -40°C is 1.5mS / cm, the conductivity...

Embodiment 2

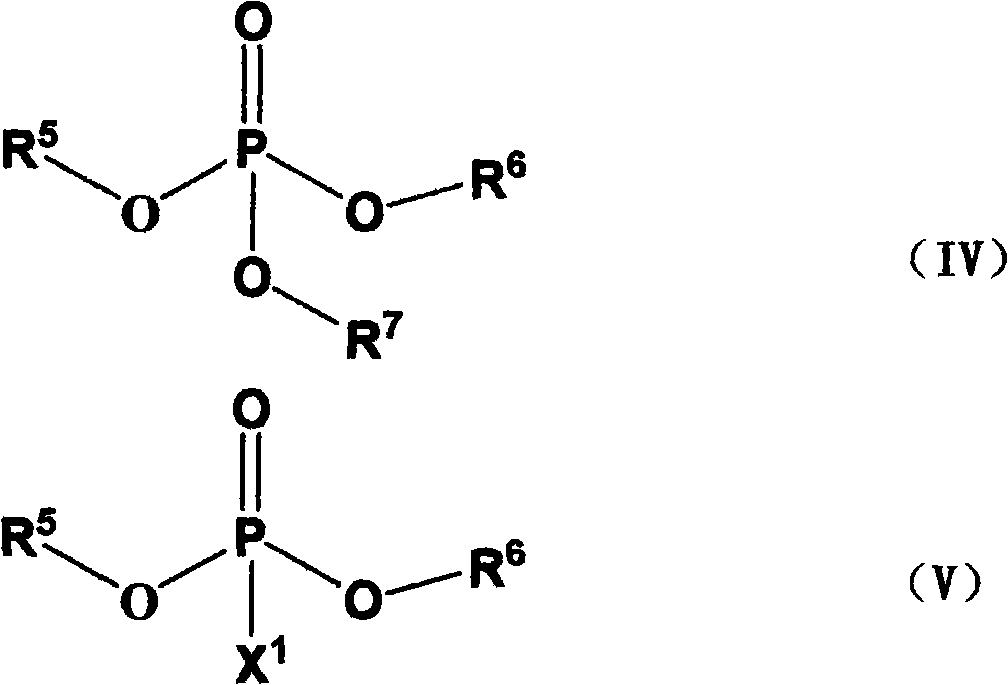

[0037] Electrolyte preparation: dry lithium bis(fluorosulfonyl)imide (Li[FSI]) in vacuum, ethyl methyl carbonate (EMC) and trimethyl phosphate (TMP) of organic solvent component B are dried and placed in vacuum gloves In the box (water content less than 1ppm). Weigh 14.018g Li[FSI] and 3.798g LiPF6 in beaker, under magnetic stirring, slowly join in the mixed solvent ( EMC:TMP=1:1, volume ratio), prepared into 1.0M electrolyte solution, sealed and stored for later use.

[0038] Conductivity measurement: Add the above electrolyte solution dropwise to a glass conductivity cell with platinum electrodes at both ends, use GDW6005 high and low temperature test chamber to control the temperature, measure impedance spectrum (5Hz-13MHz) with HP4192 impedance spectrometer, and obtain the temperature range Conductivity from -60°C to 60°C. The conductivity measured at -60°C is 0.9mS / cm, the conductivity at -40°C is 2.0mS / cm, the conductivity at -20°C is 2.6mS / cm, and the conductivity at ...

Embodiment 3

[0041] Electrolyte preparation: lithium bis(fluorosulfonyl)imide (Li[FSI]) was vacuum-dried, together with lithium hexafluorophosphate, and organic solvent components of dimethyl phosphate (TMMP) and triethoxyboroxane ( TEOBX) was dried and placed in a vacuum glove box (water content less than 1ppm). Weigh 14.018g Li[FSI] in a beaker, then weigh 3.798g lithium hexafluorophosphate and add it to the beaker. Under cooling and magnetic stirring, slowly add dimethyl methyl phosphate (TMMP) with a total volume of 100 ml in several times. and triethylboroxane (TEOBX) in a mixed solvent (DMMP: TEOBX = 3: 1 volume ratio) to prepare a 1M electrolyte solution, sealed and stored for use.

[0042] Conductivity measurement: Add the above electrolyte solution dropwise to a glass conductivity cell with platinum electrodes at both ends, use GDW6005 high and low temperature test chamber to control the temperature, measure impedance spectrum (5Hz-13MHz) with HP4192 impedance spectrometer, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com