Alprostadil injection preparation

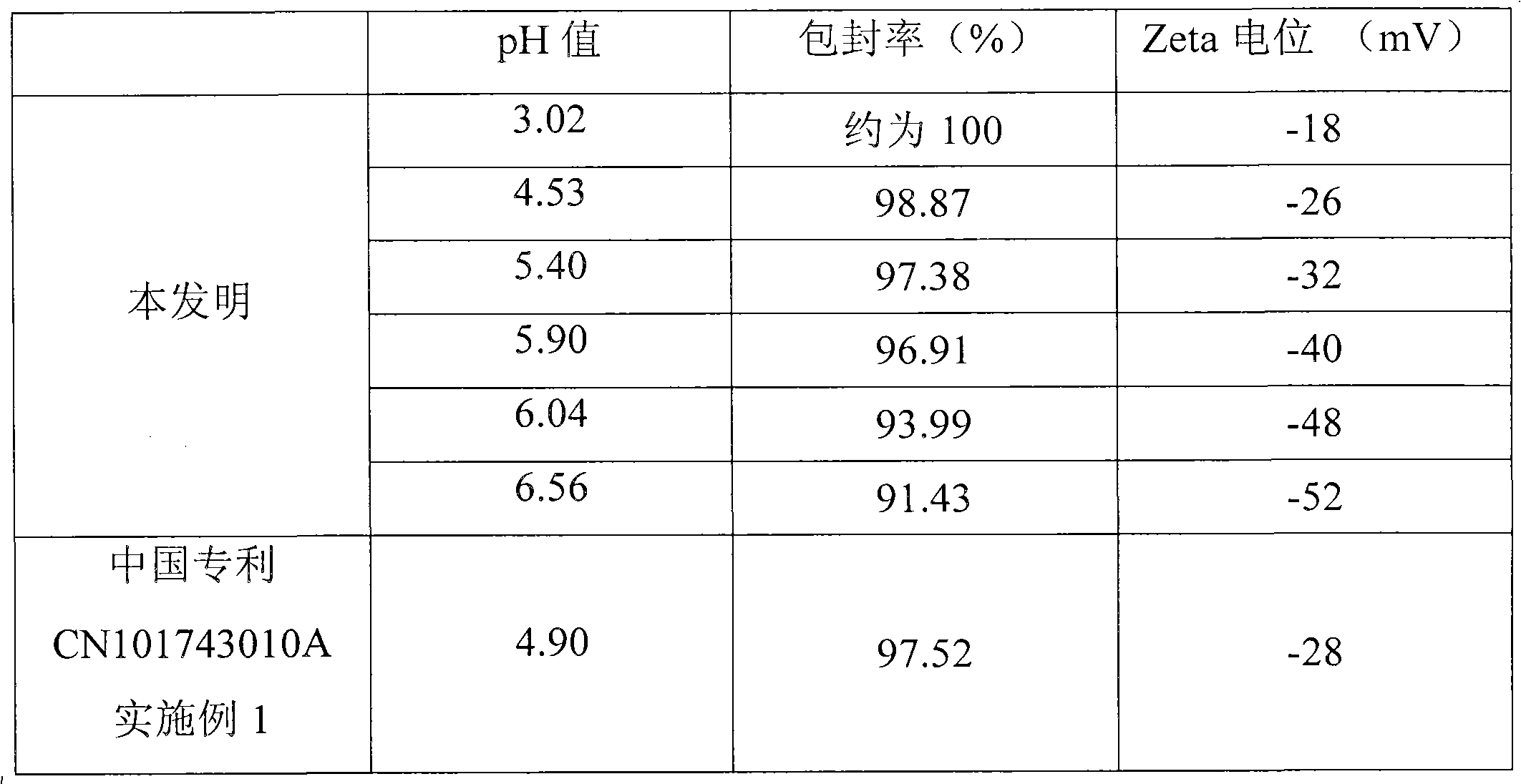

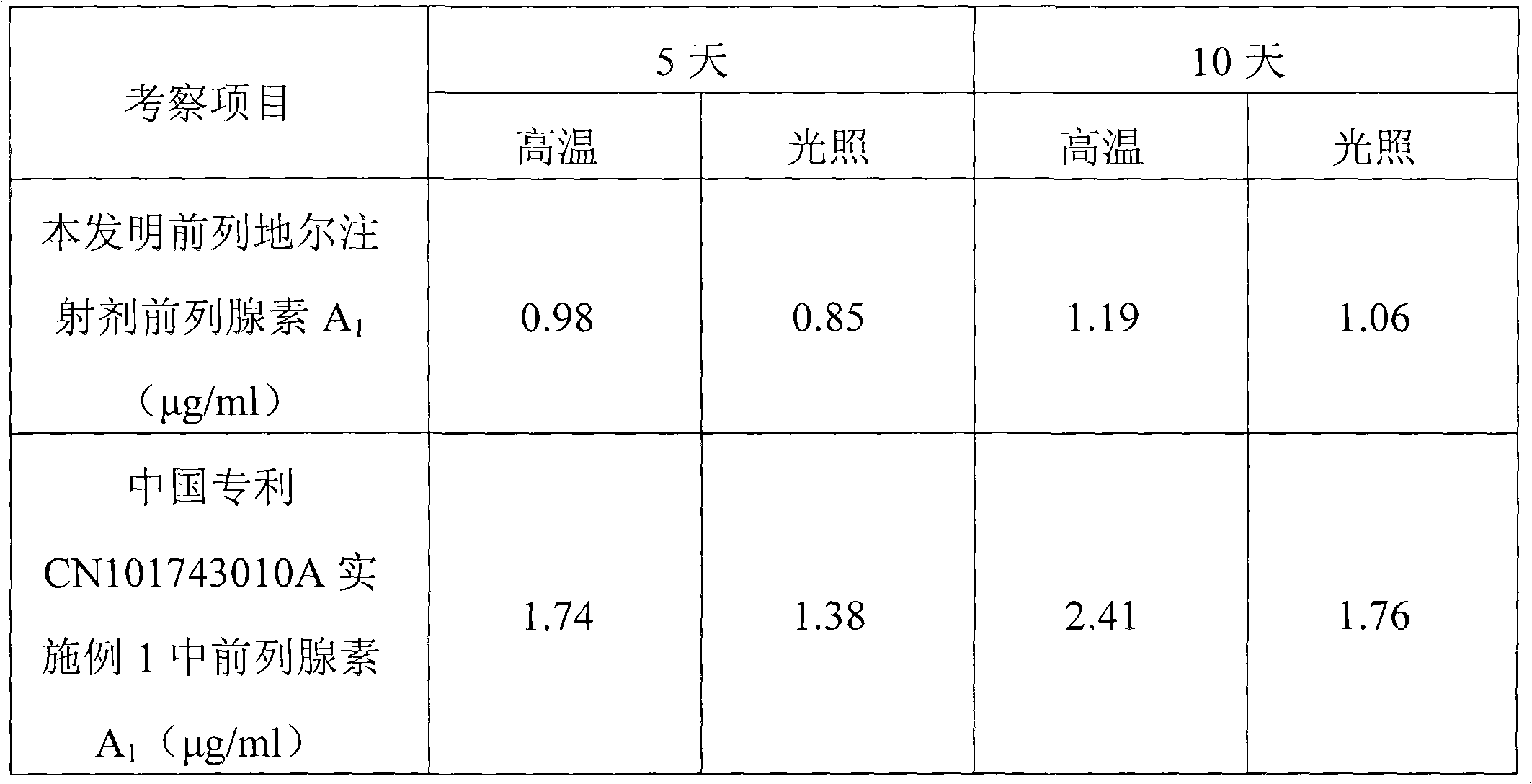

A technology of alprostadil and injection preparations, which is applied in the field of medicine and can solve the problems of poor water solubility of alprostadil, easy generation of degraded impurities, strong irritation of blood vessels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] An alprostadil injection preparation is characterized in that in the injection, 0.01 g of alprostadil, 200 g of soybean oil, 36 g of phospholipids, 50 g of glycerin, and 4.8 g of oleic acid.

[0055] (1) Take glycerin, add water for injection, make it dissolve, make glycerin aqueous solution, keep the temperature: 40-50 ℃, use it as the water phase, and set aside;

[0056] (2) Weigh oleic acid, add activated carbon for needles according to 1% of the mass, stir at 60°C for 30min, filter, and set aside;

[0057] (3) Mix phospholipids with soybean oil, stir to dissolve, mix evenly, and keep the temperature: 40-50°C as the oil phase;

[0058] (4) Oleic acid and alprostadil are added to the oil phase, stirred, mixed evenly, and set aside;

[0059] (5) (1) and (4) are mixed, and the homogenizer is sheared at high speed to form uniform colostrum;

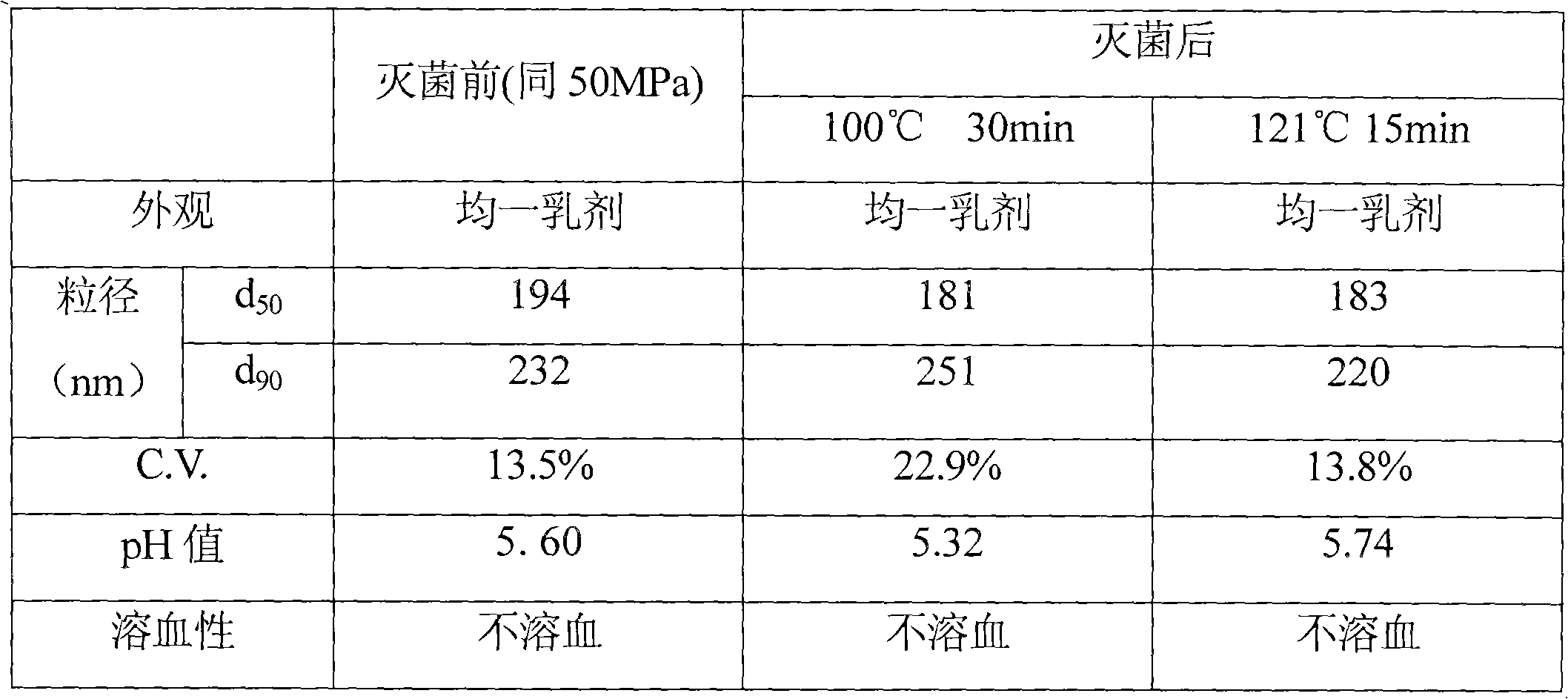

[0060] (6) Adjust the pH value of the obtained colostrum to 5.4-6.0, after mixing evenly, pass through the nanometer machine 5 tim...

Embodiment 2

[0063] An alprostadil injection preparation is characterized in that in the injection, 0.01 g of alprostadil, 200 g of soybean oil, 36 g of phospholipids, 50 g of glycerin, and 4.8 g of oleic acid.

[0064] (1) Take glycerin, add water for injection, dissolve, and make 7.5% glycerin aqueous solution, as the water phase, for subsequent use;

[0065] (2) (1) and phospholipid are quickly sheared to uniform dispersion with a homogenizer;

[0066] (3) Weigh oleic acid, add activated carbon for needles according to 1% of the mass, stir at 60°C for 30min, filter, and set aside;

[0067] (4) get alprostadil, oleic acid and soybean oil and mix, stir and dissolve, mix homogeneously, as oil phase;

[0068] (5) (1) and (4) are mixed, and the homogenizer is sheared at high speed to form uniform colostrum;

[0069] (6) Adjust the pH value of the obtained colostrum to 5.5, after mixing evenly, pass through the nanometer machine 5 times at 50MPa to obtain lipid microspheres with uniform par...

Embodiment 3

[0072] An alprostadil injection preparation is characterized in that in the injection, 0.01 g of alprostadil, 200 g of soybean oil, 36 g of phospholipids, 50 g of glycerin, and 4.8 g of oleic acid.

[0073] (1) Take glycerin, add water for injection, dissolve, and make 7.5% glycerin aqueous solution, as the water phase, for subsequent use;

[0074] (2) (1) and phospholipid are quickly sheared to uniform dispersion with a homogenizer;

[0075] (3) Weigh oleic acid, add activated carbon for needles according to 1% of the mass, stir at 60°C for 30min, filter, and set aside;

[0076] (4) get alprostadil, oleic acid and soybean oil and mix, stir and dissolve, mix homogeneously, as oil phase;

[0077] (5) (1) and (4) are mixed, and the homogenizer is sheared at high speed to form uniform colostrum;

[0078] (6) Adjust the pH value of the obtained colostrum to 5.50, after mixing evenly, pass through a nanomachine at 50MPa for 5 times to obtain lipid microspheres with a uniform part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com