Grinding wheel dresser of grinder

A grinding wheel dresser and grinding machine technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of large size, heavy weight of Z-axis feed mechanism, long stroke, etc., to achieve Ease of processing, guaranteed sensitivity, and lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

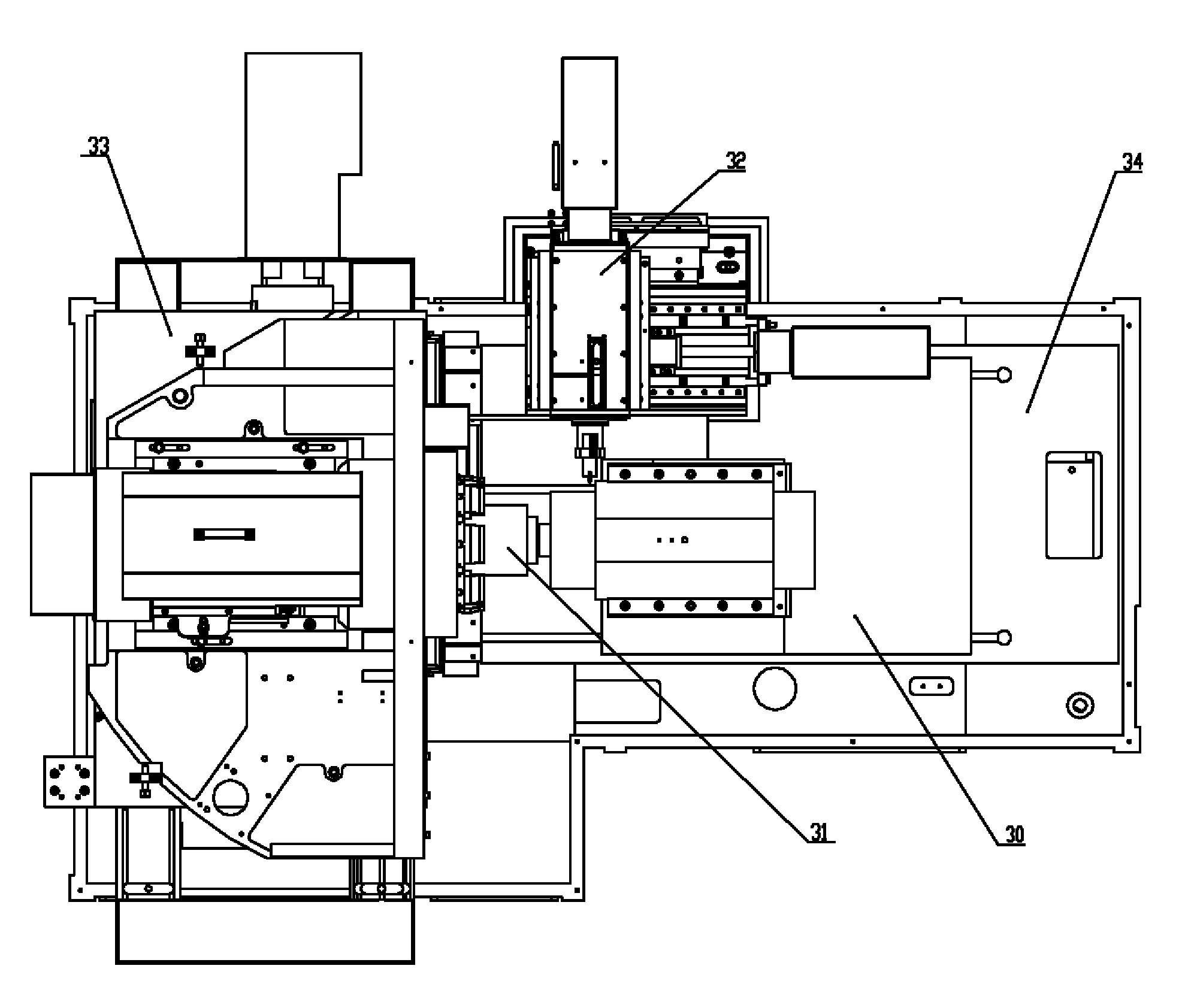

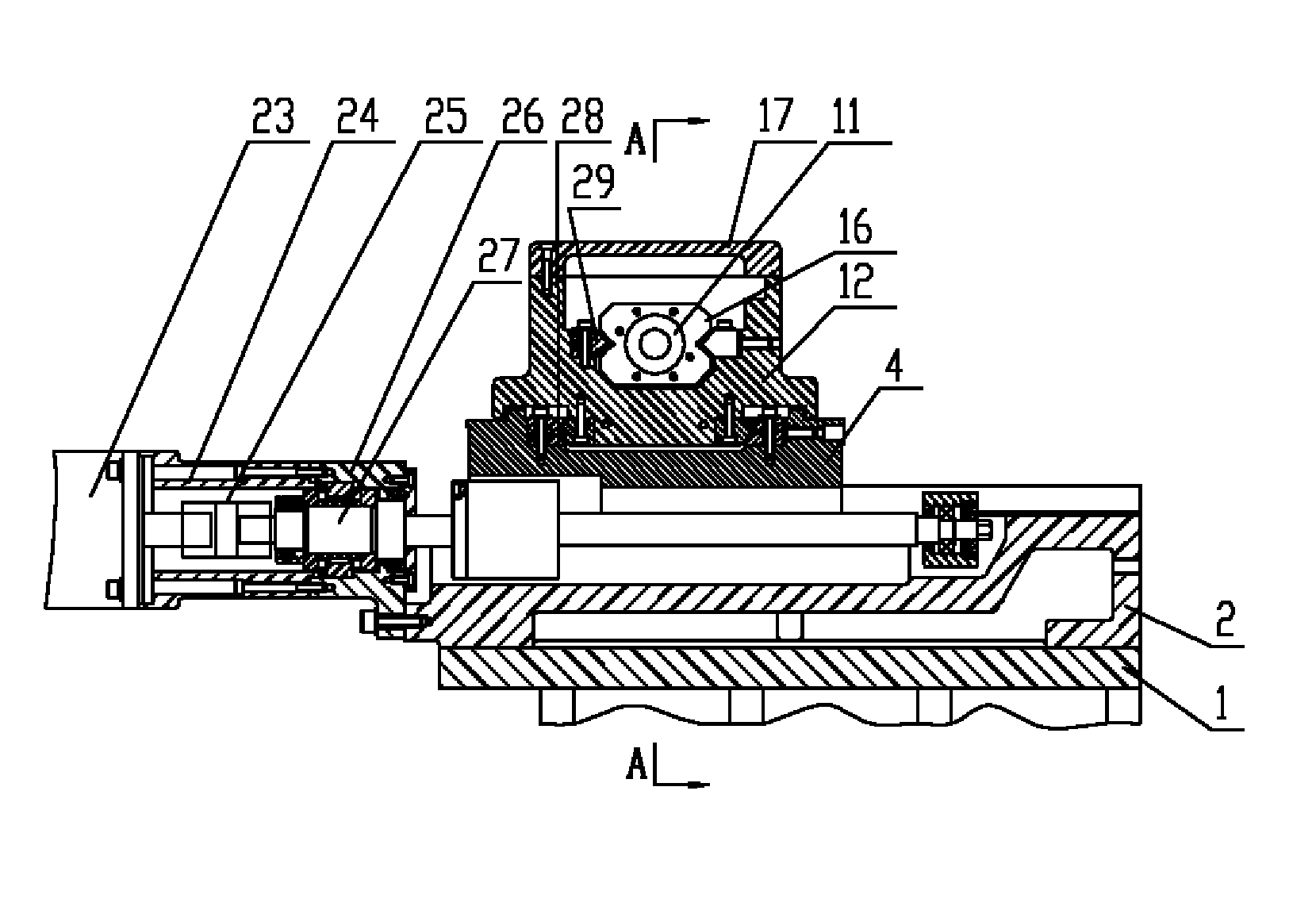

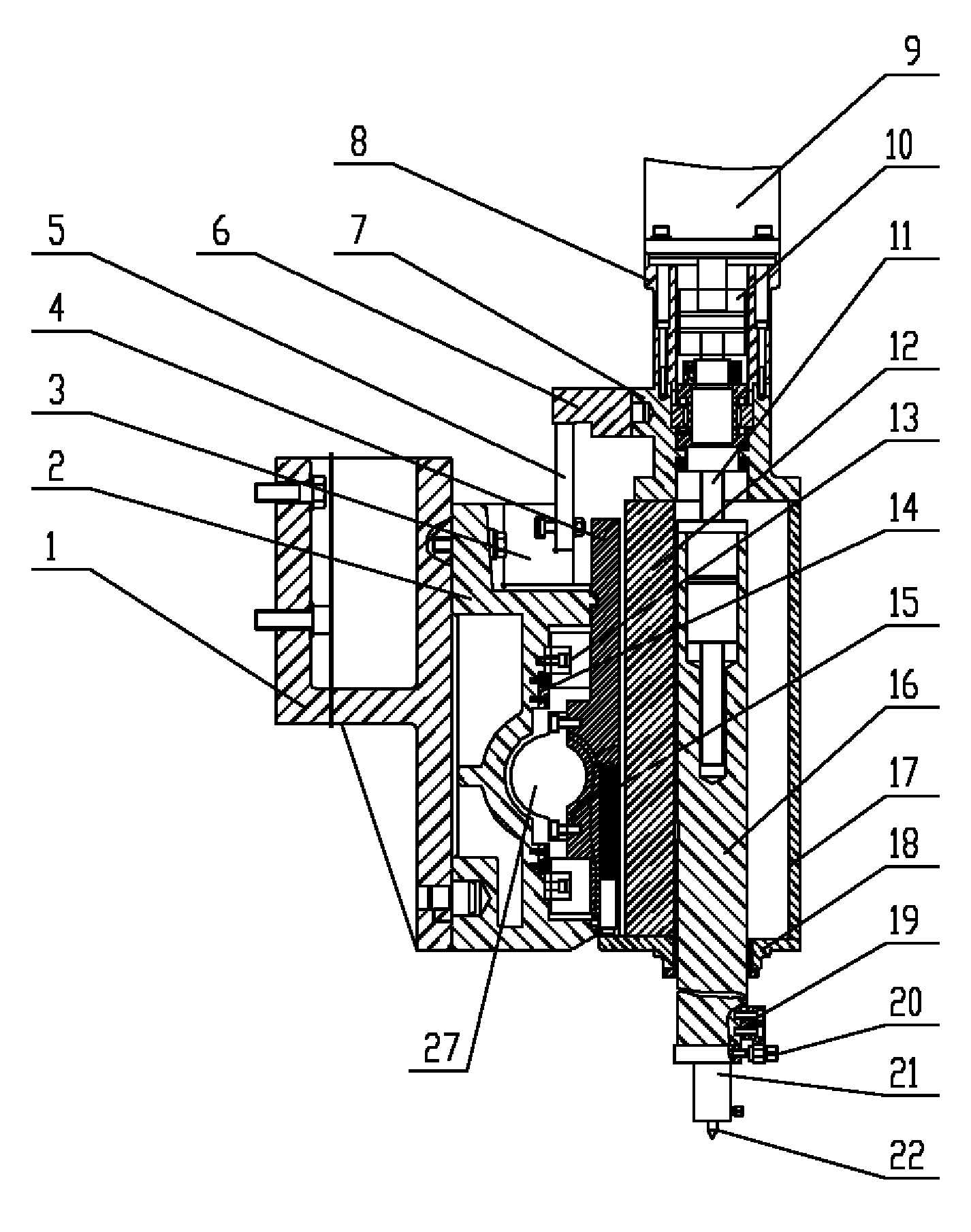

[0017] See figure 1 , figure 2 , image 3 , the overall layout of the grinding machine includes a Z-axis feed mechanism 30, a grinding wheel 31, a grinding wheel dresser 32, an X-axis feed mechanism 33, and a bed 34. The grinding wheel dresser 32 includes a diamond pen 22, a W-axis drive shaft, and a U-axis drive shaft. The diamond pen 22 is connected to the W-axis drive shaft, and the W-axis drive shaft is supported on the carriage driven by the U-axis drive shaft. The driving direction of the U-axis drive shaft is parallel to the feed direction of the Z-axis feed mechanism 30 of the grinding machine, and the U-axis drives The shaft is secured to the bed 34 of the grinder by a dresser base.

[0018] The W-axis drive shaft specifically includes a W-axis servo motor 9, a W-axis coupling 10, a W-axis ball screw 11, and a W-axis slide plate 16. The output end of the W-axis servo motor 9 is connected to the W-axis ball wire through the W-axis coupling 10. The input end of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap