Catalysis wet-type oxidation treatment method for cyanogen-containing wastewater

A technology that catalyzes wet oxidation and treatment methods, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as secondary pollution, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] 2 g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 30ml water to make solution I, and 98 grams of 20-80 mesh TiO 2 Carrier impregnation solution I, dried at 100°C for 12 hours, and calcined at 600°C for 5 hours to obtain catalyst precursor I; 1.5 g of anhydrous RuCl 3 Dissolved in 30ml of water to form solution II, impregnated solution II with the prepared catalyst precursor I, dried at 80°C for 24 hours, and calcined at 700°C for 4 hours to obtain a catalyst.

[0011] Utilize the above-mentioned prepared catalyst to treat the industrial waste water with 4217mg / l total cyanide and 100769mg / l COD, through a fixed bed reactor, at a reaction temperature of 260°C, a reaction pressure of 7.0Mpa, and a liquid space velocity of 2.0 hours -1 , with air as the reaction gas raw material, under the condition that the volume ratio of gas to liquid is 150:1 under the standard state, the COD removal rate is 97.5%, and the total cyanide is reduced to 2mg / l.

Embodiment 2~17

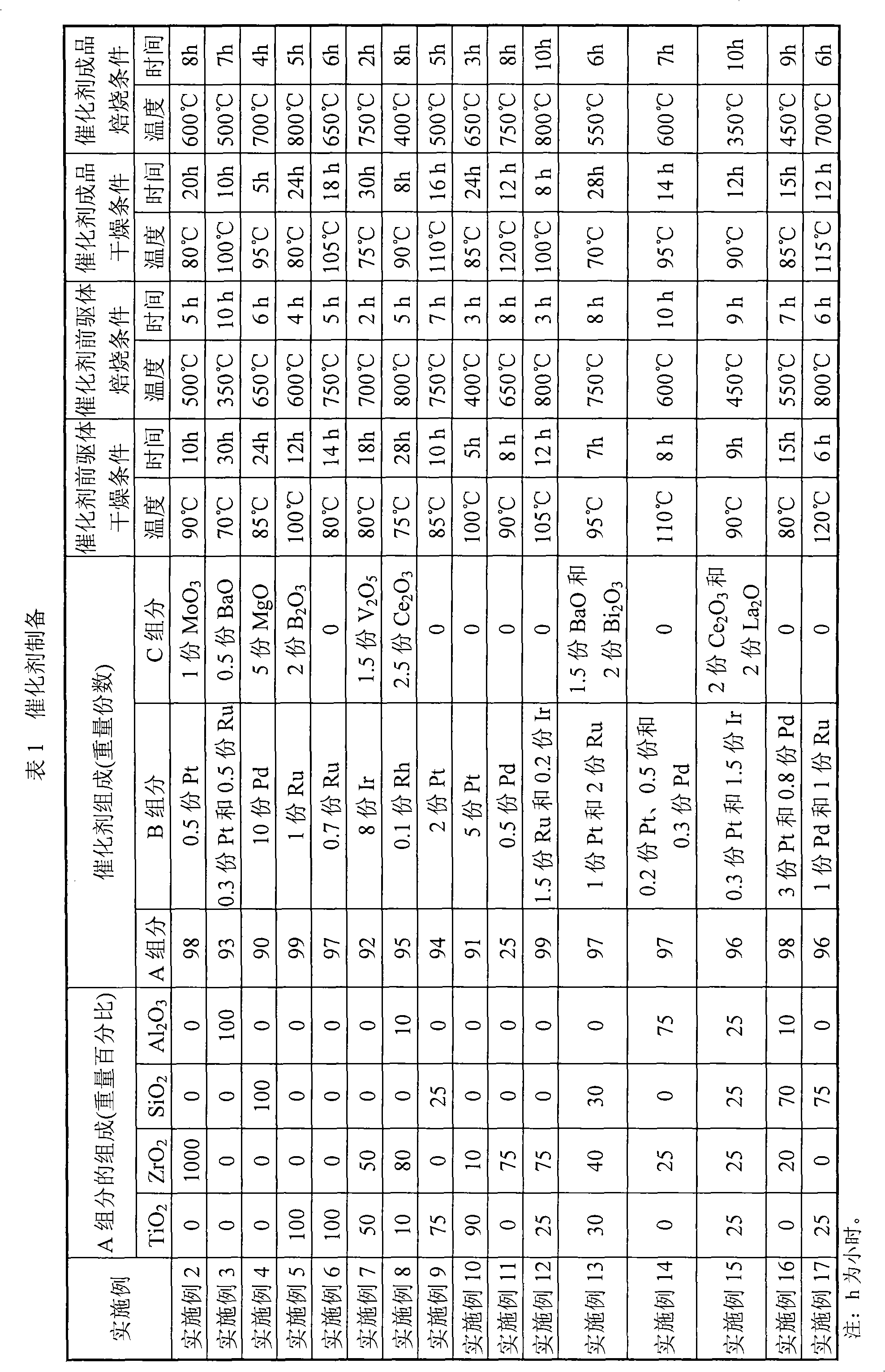

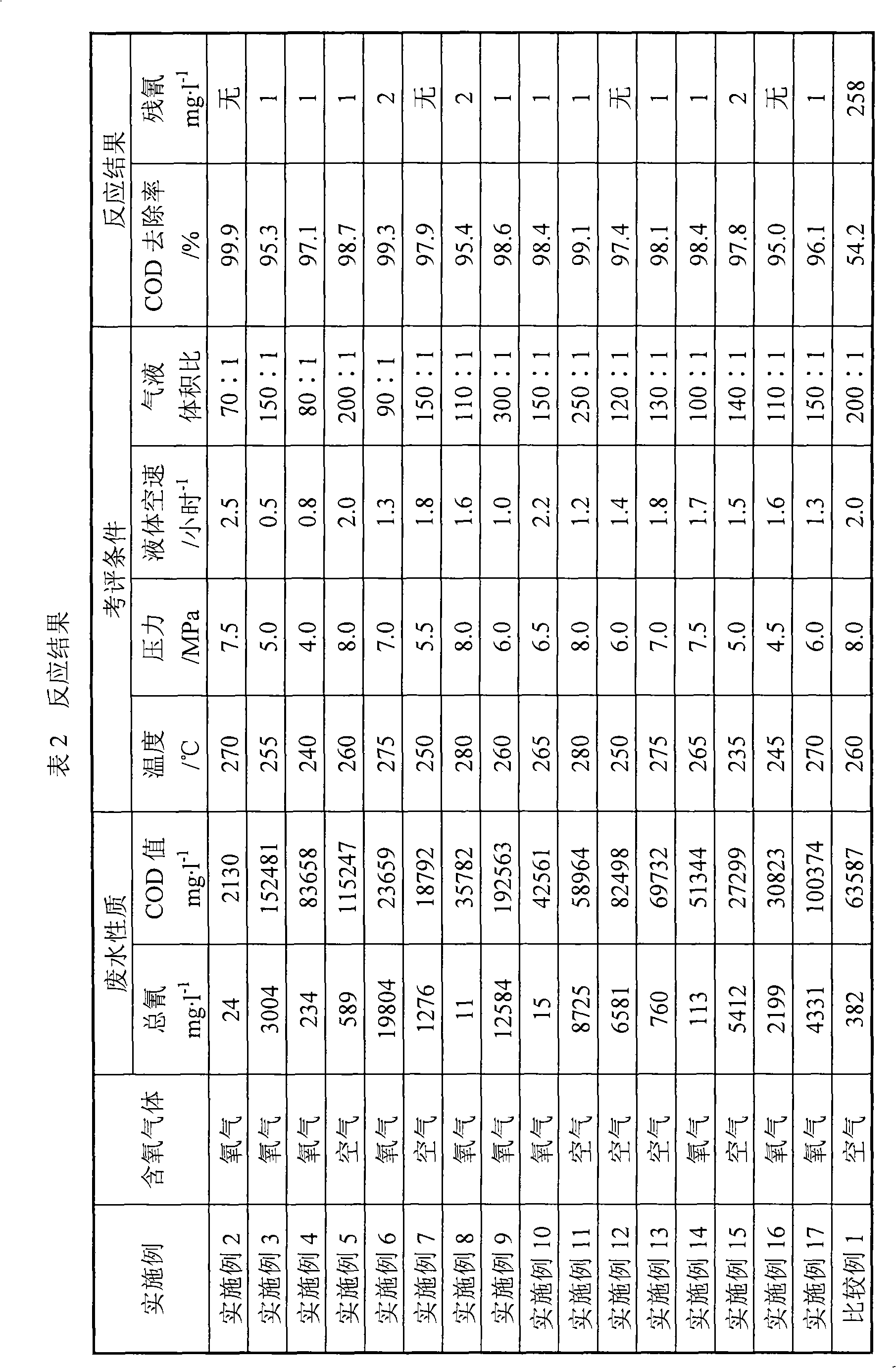

[0013] The preparation method is the same as in Example 1, only the raw materials, component ratio and preparation conditions are changed. The prepared catalyst is shown in Table 1, and the reaction results are shown in Table 2.

Embodiment 18~26

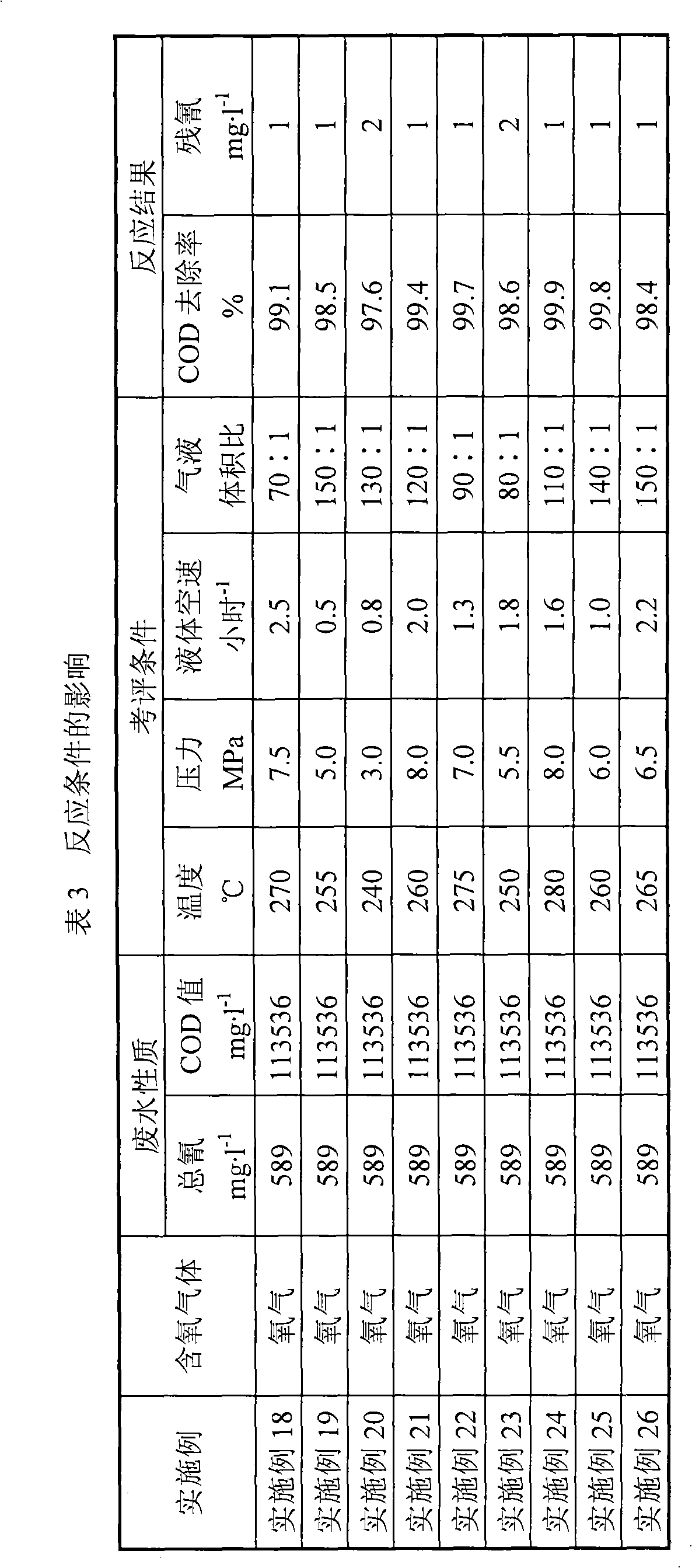

[0015] The catalyst prepared in Example 5 was adopted, but the reaction conditions were changed, and the specific results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com