Cold box freezing and blocking processing technology for tertiary refrigeration system

A refrigeration system and freeze-blocking technology, applied in the direction of hydrocarbon cracking, hydrocarbon purification/separation, hydrocarbons, etc., can solve uneconomical and unrealistic problems, and achieve the goal of avoiding parking, reducing trouble, and reducing power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Firstly, a drier is set up to further dry the polymer grade propylene introduced by the device and used to prepare the ternary refrigerant to make its dew point <-100°C.

[0061] Second, set up backup equipment at locations that are prone to freezing and blockage, and switch and clean them regularly.

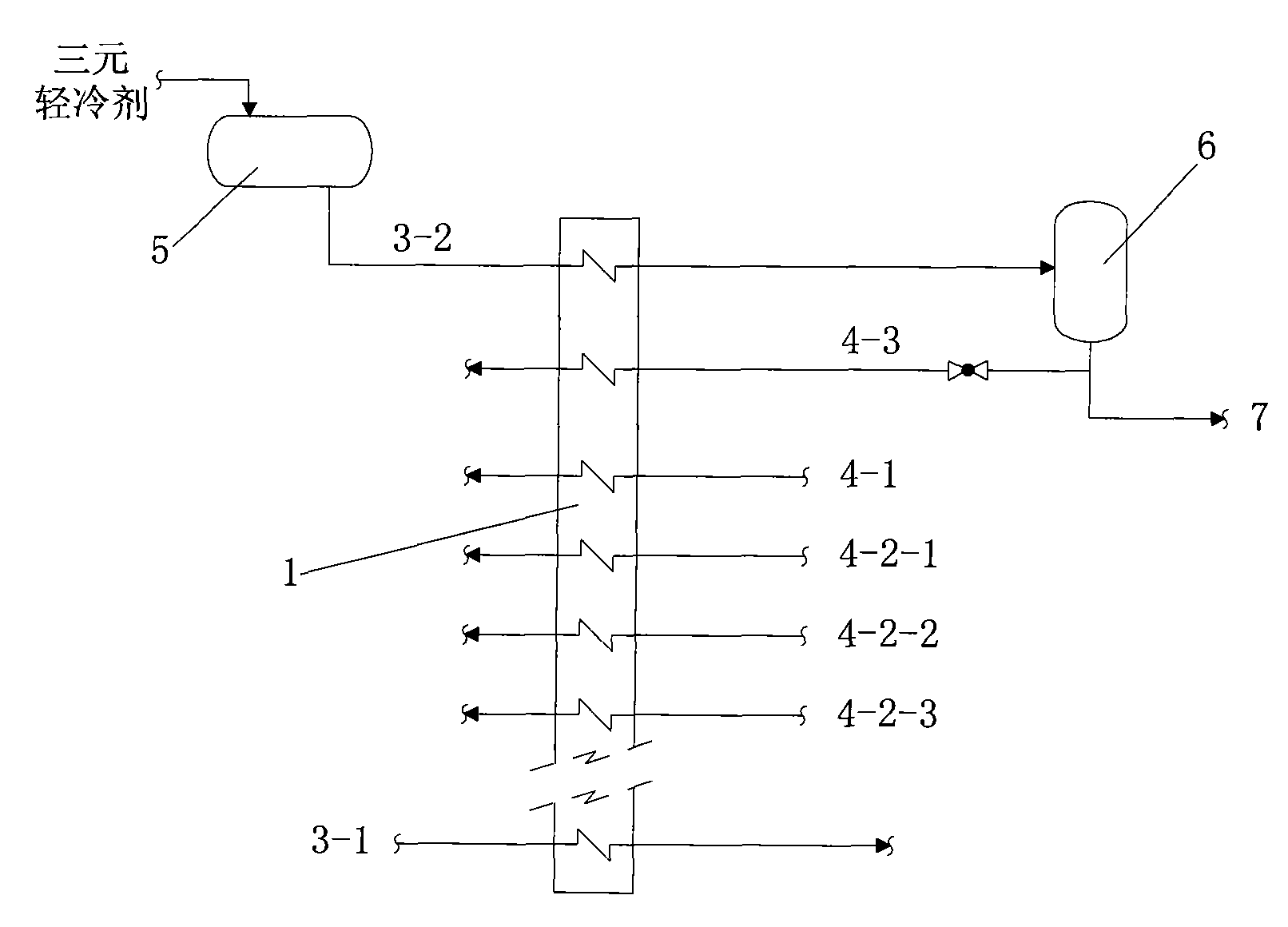

[0062] 1. Supercooled runner of light refrigerant

[0063] From the above description, it can be known that in the subcooling heat exchanger of the original light refrigerant, there are multiple flow channels such as light refrigerant subcooling, light refrigerant refrigeration, cracked gas, hydrogen and various methane tail gases, and the pipeline is relatively small. Many, the equipment is huge, which is not conducive to direct all backup.

[0064] 1 new device

[0065] Such as figure 2 As shown, the subcooling channel of the light refrigerant is separated separately, and two identical auxiliary heat exchangers are set up, one is on and the other is standby, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com