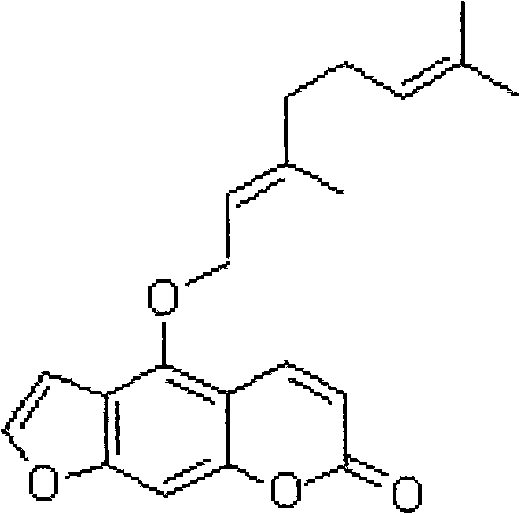

Method for extracting bergamottin from grapefruit peel

A technology of bergamot and grapefruit peel, which is applied in the field of extraction and purification of bergamot, can solve the problem of no subdivision and achieve the effect of complete separation and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Get fresh pomelo peel 10kg (bergamotin content 2.1%) and pack into extraction jar, seal, CO 2 After being purified by the purifier, it is cooled and liquefied in the liquefaction tank. into the storage tank with a high-pressure metering pump to CO 2 Send it into the preheater, heat it to 40°C through the preheater, enter the extraction tank from the lower part of the extraction tank, gradually control the pressure of the extraction tank to 20MPa with a pressure regulating valve, and stabilize the pressure in the separation tower at 8MPa, and extract dynamically for 2 hours. After shutting down, 888g of precipitated solid was released as crude product, which was dispersed in 4.5L of 80% ethanol, mixed with a small amount of polyamide resin, evaporated to dryness, and the polyamide resin with a column volume of 5L was successively washed with 10L deionized water, 10% ethanol, 60 % ethanol for elution, collect 60% ethanol eluate, concentrate under reduced pressure to obta...

Embodiment 2

[0031] Get fresh pomelo peel 10kg (bergamotin content 2.2%) and pack into extraction jar, seal, CO 2 After being purified by the purifier, it is cooled and liquefied in the liquefaction tank. into the storage tank with a high-pressure metering pump to CO 2 Send it into the preheater, heat it to 45°C through the preheater, enter the extraction tank from the lower part of the extraction tank, gradually control the pressure of the extraction tank to 35MPa with a pressure regulating valve, stabilize the pressure in the separation tower at 9MPa, and extract dynamically for 2.5 hours. After shutting down, 910g of precipitated solid was released as a crude product, which was dispersed in 7L of 90% ethanol, mixed with a small amount of polyamide resin, evaporated to dryness, and adsorbed by polyamide resin with a volume of 5L on the column. % ethanol for elution, collect 75% ethanol eluate, concentrate under reduced pressure to extract, recrystallize 4 times with petroleum ether, and...

Embodiment 3

[0033] Get fresh pomelo peel 10kg (bergamotin content 2.0%) and pack into extraction jar, seal, CO 2 After being purified by the purifier, it is cooled and liquefied in the liquefaction tank. into the storage tank with a high-pressure metering pump to CO 2 Send it into the preheater, heat it to 40°C through the preheater, enter the extraction tank from the lower part of the extraction tank, gradually control the pressure of the extraction tank to 30MPa with a pressure regulating valve, and stabilize the pressure in the separation tower at 10MPa, and extract dynamically for 2 hours. After shutting down, 918g of precipitated extract was released as a crude product, dispersed in 6.4L of 85% ethanol, mixed with a small amount of polyamide resin, evaporated to dryness, and adsorbed by polyamide resin with a volume of 5L on the column, followed by 12L deionized water and 40% ethanol , 80% ethanol eluate, collect 80% ethanol eluate, concentrate under reduced pressure to extractum, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com