Silver conductive adhesive as well as preparation method and application thereof

A technology of conductive silver glue and conductive materials, applied in the direction of conductive adhesives, adhesives, adhesive additives, etc., can solve the problems of long curing time of conductive adhesives, unfavorable production, long production cycle, etc., to shorten the curing time and promote the reaction , the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

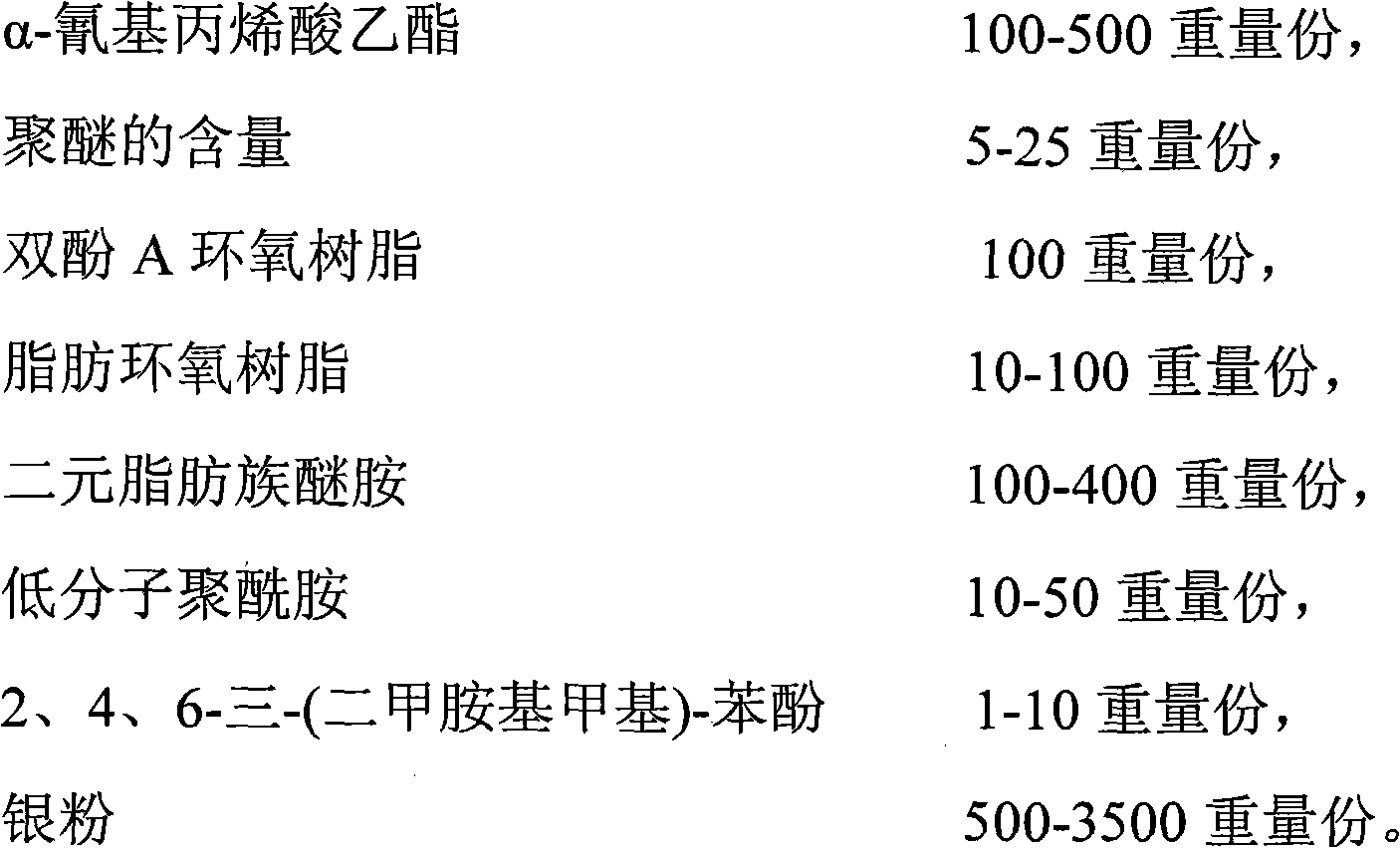

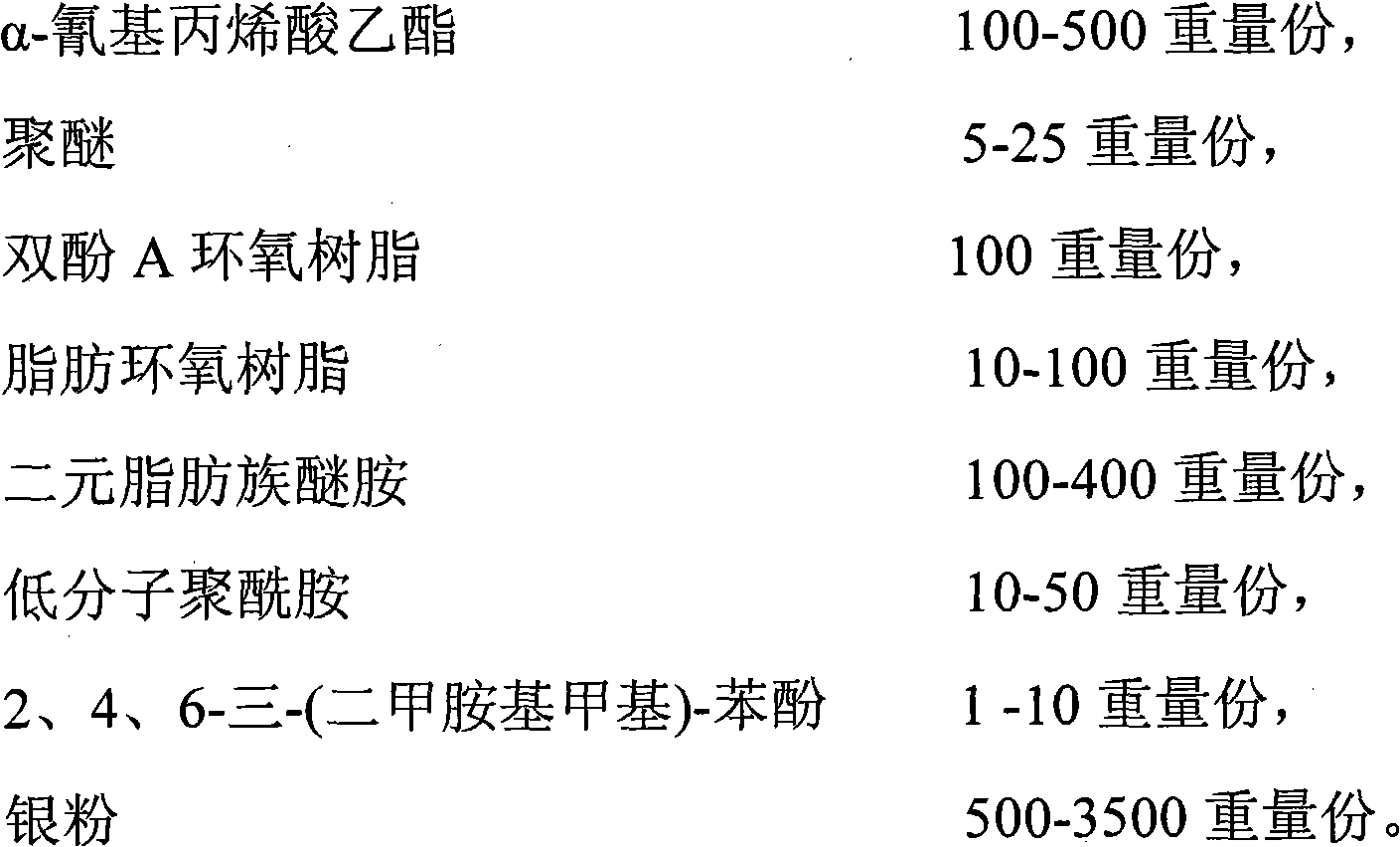

[0018] The present invention also provides a preparation method of conductive silver glue, the method is at normal temperature, mix base resin, curing agent, curing accelerator, α-ethyl cyanoacrylate and polyether evenly, then add conductive material and stir and mix Evenly obtain the conductive silver glue; Wherein, the base resin is epoxy resin, the curing agent is dibasic aliphatic ether amine and low molecular polyamide, and the curing accelerator is, 4,6-three-(two methylaminomethyl)-phenol.

[0019] The invention also provides an application of the conductive silver glue, comprising coating the conductive silver glue on the surface of the base material in an air environment and curing it.

[0020] According to the application of the conductive silver glue provided by the present invention, preferably, at room temperature, the curing time of the conductive silver glue on the surface of the substrate is 5-15 minutes.

[0021] According to the conductive silver glue provid...

Embodiment 1

[0024] At normal temperature, the epoxy equivalent of 100 is the bisphenol A epoxy resin of 250, the aliphatic epoxy resin of 150 is the epoxy equivalent of 50, the dibasic aliphatic epoxy resin of 2000 molecular weight is 250 Ether amine, low molecular weight polyamide with a molecular weight of 700, 30 parts by weight, 300 parts by weight of ethyl α-cyanoacrylate and 15 parts by weight of polyether are fully mixed and uniform, and then 6 parts by weight of DMP-30 are added and mixed evenly , adding 1500 parts by weight of flaky silver powder with an average size of 4 microns, stirring and dispersing to obtain conductive silver paste A1.

Embodiment 2

[0026] At normal temperature, the bisphenol A epoxy resin that 100 weight parts epoxy equivalents are 200 by weight, the aliphatic epoxy resin that 40 weight parts epoxy equivalents are 200, the dibasic aliphatic ether amine that 200 weight parts molecular weights are 1500, 20 parts by weight of low-molecular polyamide with a molecular weight of 600, 200 parts by weight of ethyl α-cyanoacrylate and 10 parts by weight of polyether are fully mixed and uniform, and then 3 parts by weight of DMP-30 are added and mixed well, and 1200 parts by weight of Flake silver powder with an average size of 6 microns was stirred and dispersed to obtain conductive silver paste A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com