Pressure-sensitive adhesive for PET (Polyester) adhesive tapes and preparation method thereof

A technology of pressure-sensitive adhesives and adhesive tapes, which is applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., and can solve problems such as residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A pressure-sensitive adhesive for PET adhesive tape and its preparation method

[0025] Butyl acrylate 150kg;

[0026] Isooctyl acrylate 250kg;

[0027] Acrylic acid 7kg;

[0028] Methyl methacrylate 30kg;

[0029] Vinyl acetate 30kg;

[0030] 2-hydroxyethyl methacrylate 12kg;

[0031] Benzoyl peroxide 3kg;

[0032] Ethyl acetate 260kg;

[0033] Toluene 260kg;

[0034] Tackifying resin 195kg.

[0035] The preparation method is as follows:

[0036] (1) Add butyl acrylate, isooctyl acrylate, acrylic acid, methyl methacrylate, vinyl acetate, and 2-hydroxyethyl methacrylate to toluene and ethyl acetate and stir;

[0037] (2) Heating to 80-85°C in the reaction kettle, then adding 0.7kg of benzoyl peroxide and keeping it warm for 2 hours;

[0038] (3) Add 1.5kg of benzoyl peroxide and keep warm for 4h;

[0039] (4) Finally add 0.8kg benzoyl peroxide and keep warm for 2h;

[0040] (5) Lower the temperature to about 50°C, add the tackifying resin, stir ev...

Embodiment 2 5

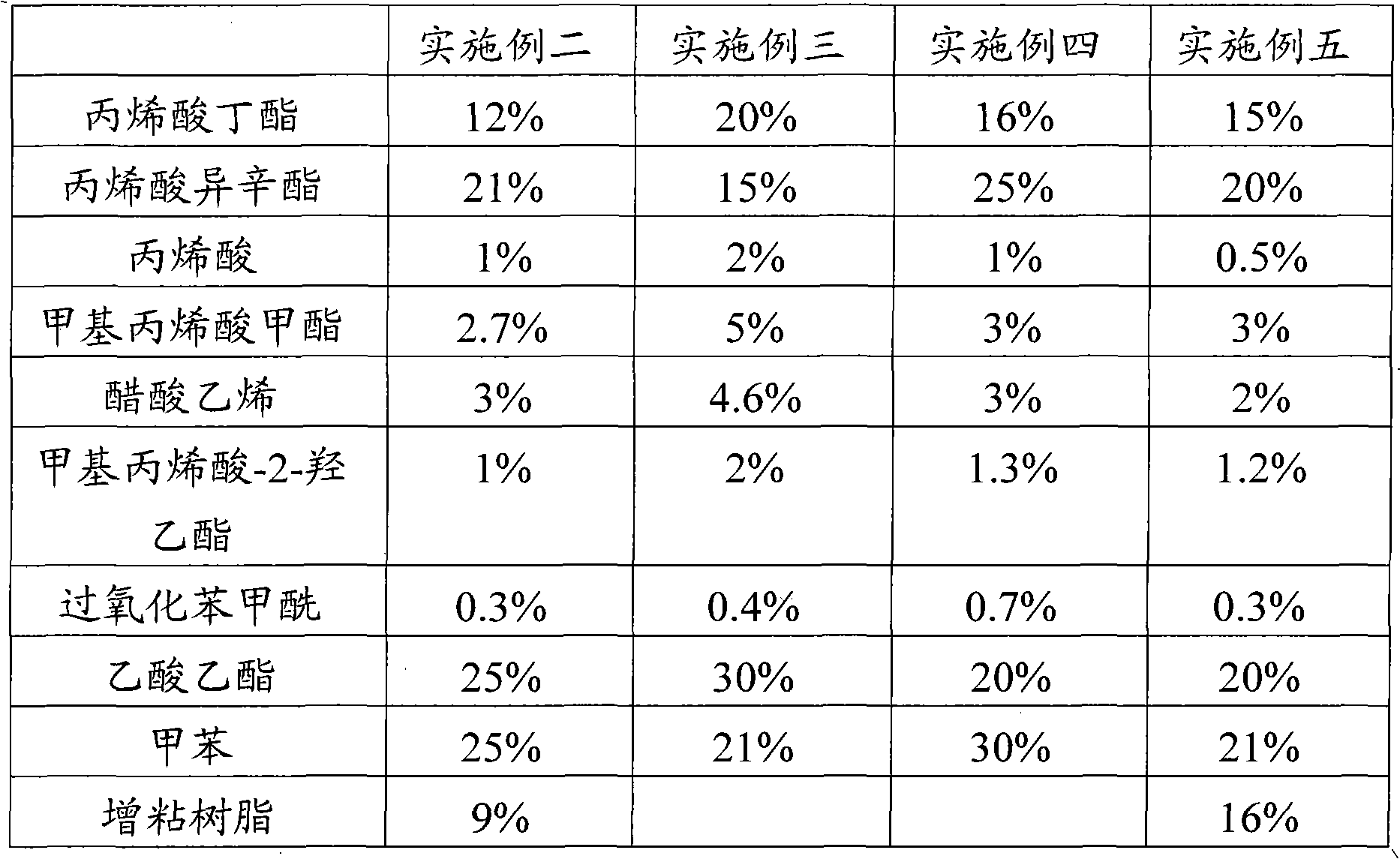

[0041] Embodiments 2-5: A pressure-sensitive adhesive for PET adhesive tape and its preparation method

[0042] 1. The raw material formula is shown in the following table:

[0043]

[0044] Two, preparation method is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com