Composite crude oil demulsifying agent

A crude oil demulsifier and composite technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems that single-dose demulsifiers are difficult to achieve demulsification effect, strong application specificity, poor universal applicability, etc., and achieve strong Interfacial activity and penetration ability, reducing strength, and promoting the effect of separation

Active Publication Date: 2011-05-04

CHINA NAT OFFSHORE OIL CORP +1

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Multi-branched demulsifiers have better interface breaking ability and demulsification performance, but single-dose crude oil demulsifiers usually have the characteristics of strong application specificity, poor universal applicability and single performance

For the complex emulsion system with strong stability in tertiary oil recovery and high oil content in the water after demulsification, it is difficult for a single-agent demulsifier to achieve the ideal demulsification effect. On the basis of the high dehydration rate of the agent, the added composite system also solves the problem of high oil content in the sewage after complex production fluid demulsification

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

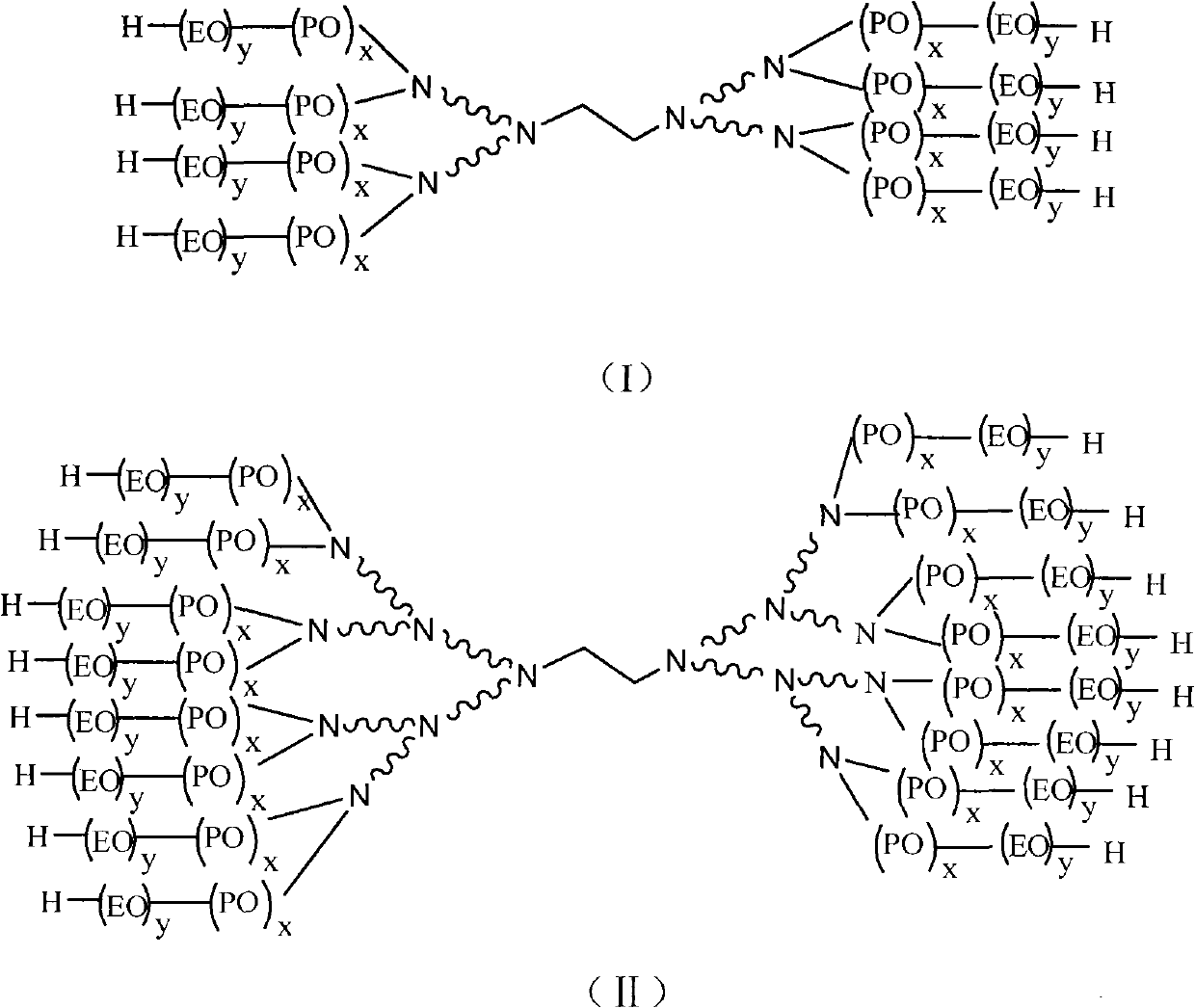

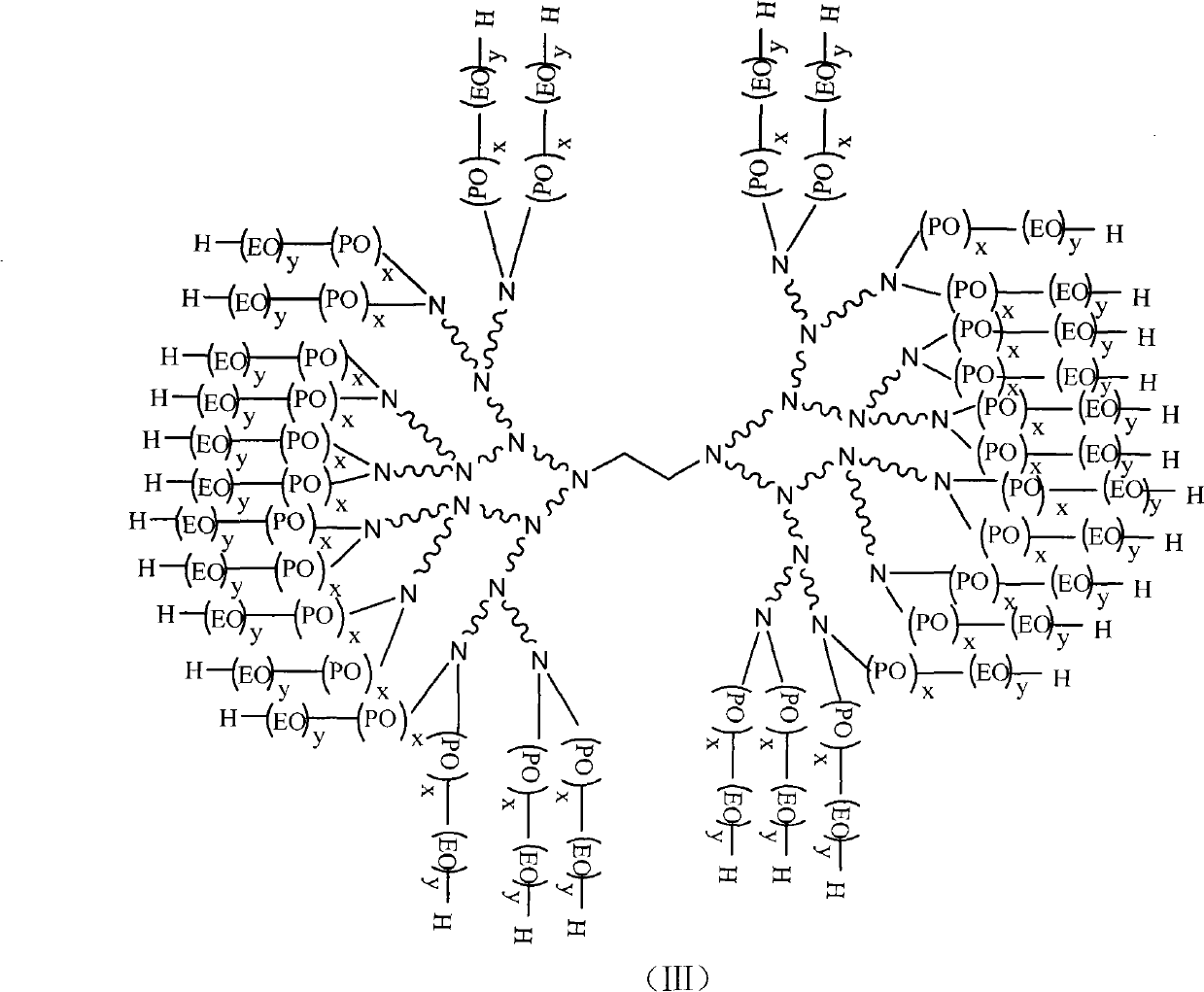

The invention discloses a composite crude oil demulsifying agent. The composite crude oil demulsifying agent consists of a polyether compound, n-dodecyl carboxylic acid and a solvent, wherein the part ratio of the total mass of the polyether compound and the n-dodecyl carboxylic acid to the mass of the solvent is (2-3):(2-3); the mass part ratio of the polyether compound to the n-dodecyl carboxylic acid is (1-6):(1-4); the polyether compound is at least one of the compounds which are shown as a formula (I), a formula (II) and a formula (III); a wavelike mark in the formula (I), the formula (II) and the formula (III) represents -CH2CH2CONHCH2CH2-; PO represents isopropoxy; EO represents ethyoxyl; x is a number of between 10 and 100; and y is a number of between 5 and 50. The composite crude oil demulsifying agent has high demulsification performance for crude oil emulsion and can be applied to the field of demulsification and dehydration of crude oil.

Description

technical field The invention relates to a crude oil demulsifier, in particular to a composite crude oil demulsifier. Background technique Crude oil demulsifier is an important chemical reagent in the process of oil extraction and gathering. With the application of tertiary oil recovery technology in major domestic oilfields, the treatment of produced fluid has become an important technical link in oilfield production, and oilfields have higher and higher performance requirements for demulsifiers. Demulsification by using a demulsifier is to add a demulsifier to the crude oil to partially replace the film-forming substances of the oil-water interface film of the crude oil emulsion to form a looser mixed film, reduce the mechanical strength and viscoelasticity of the oil-water interface film, and promote Collision aggregation and achieve the purpose of oil-water separation. Multi-branched demulsifiers have better interface breaking ability and demulsification performance, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G33/04

Inventor 檀国荣周薇王金本周继柱徐晓慧史学峰杨惠

Owner CHINA NAT OFFSHORE OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com