Colleseed oil refining equipment and method for refining colleseed oil thereof

A refining equipment, rapeseed oil crude oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems affecting the overall benefit of the rapeseed industry, weak awareness of quality and safety, and difficulty in ensuring food safety, etc., to achieve complete functions and guarantee The effect of food safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

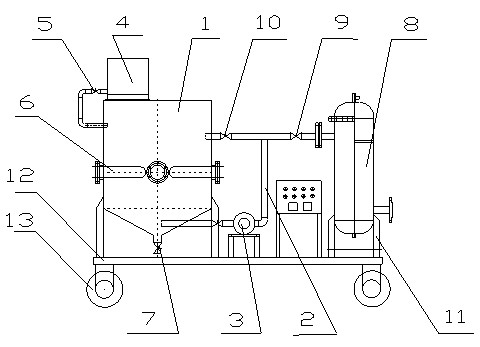

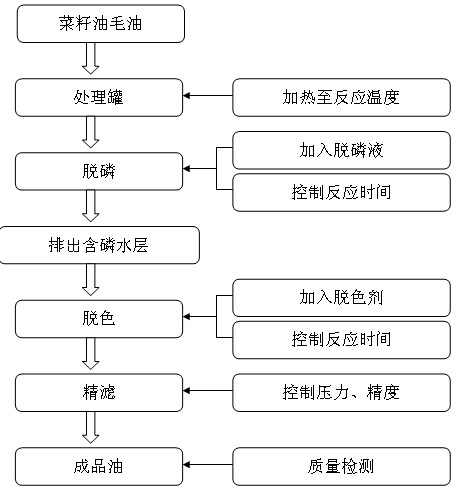

[0030] Example 1, see figure 1 , a kind of rapeseed oil refining equipment, including filtering device and processing device, the processing device includes a processing tank 1, the outlet of the processing tank 1 is connected to the inlet through an oil pump 3, a pipeline 2, and a circulation stirring valve 10 to form a closed loop and is passed through an oil pump 3 It can realize the circulation stirring of rapeseed crude oil in the treatment tank 1; the treatment tank 1 is connected with the dephosphorization liquid storage tank 4 through the solenoid valve 5, the treatment tank 1 is provided with a heater 6, and the bottom of the treatment tank 1 is provided with a ball valve 7 Phosphorus-containing water layer can be discharged; the filter device includes a fine filter tank 8, and the outlet of the treatment tank 1 is connected with the described fine filter tank 8 by an oil pump 3, a pipeline 2, and a fine filter tank valve 9; the treatment tank 1 and the fine filter tan...

Embodiment 2~10

[0037] Examples 2-10, a kind of rapeseed oil refining equipment and its method for refining rapeseed oil, its process parameters and relevant data are shown in Table 1, and the others are the same as in Example 1.

[0038] Table 1 Embodiment 2~10 process parameters and relevant data

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com