Rhizopus strains, yeast strains, distiller's yeast containing same and production method for distiller's yeast

A technology of Saccharomyces cerevisiae and Rhizopus oryzae, which is applied in the field of yeast strains and Rhizopus oryzae, can solve the problems that microorganisms cannot adapt well to each other, the taste cannot meet the needs of customers, and the taste of products cannot be adjusted, so as to achieve the effect of guaranteeing standardized control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

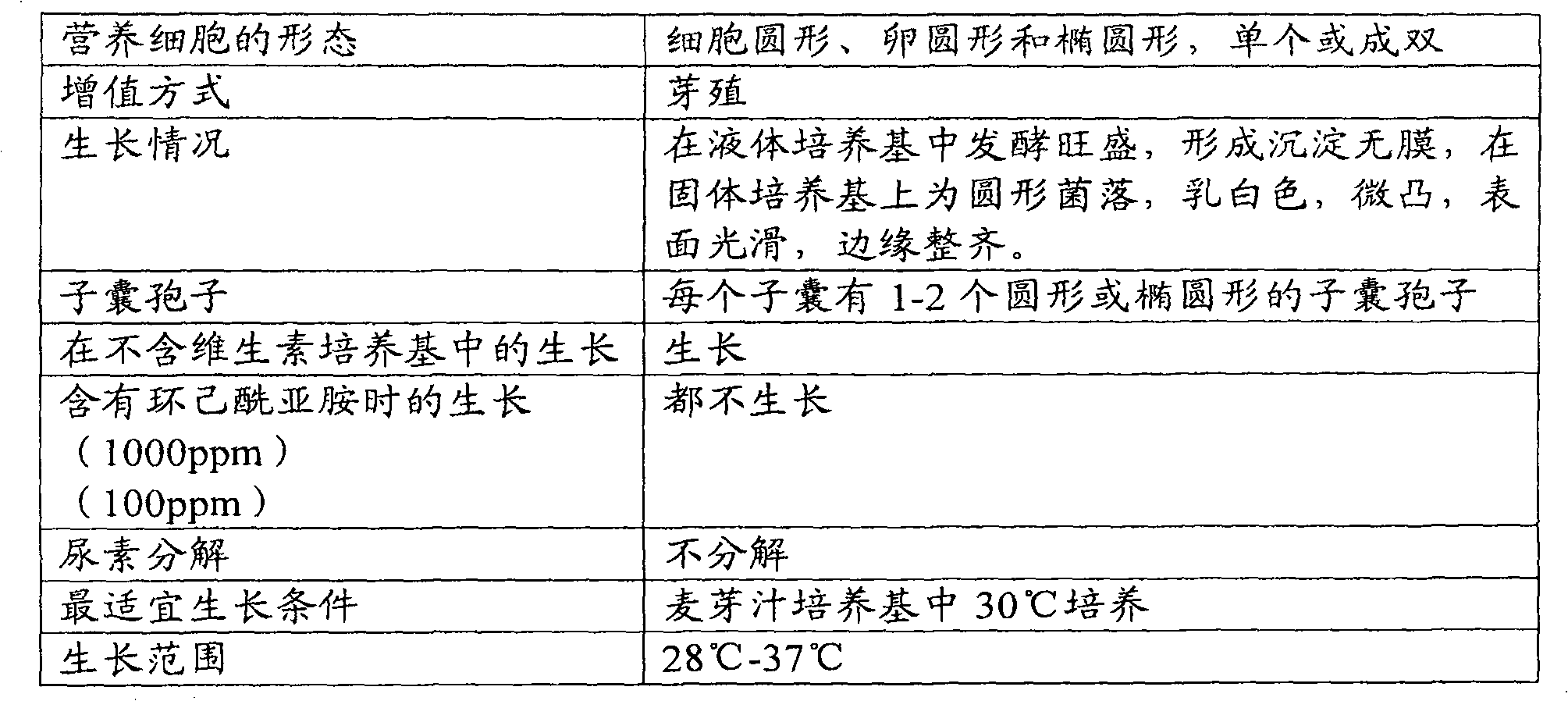

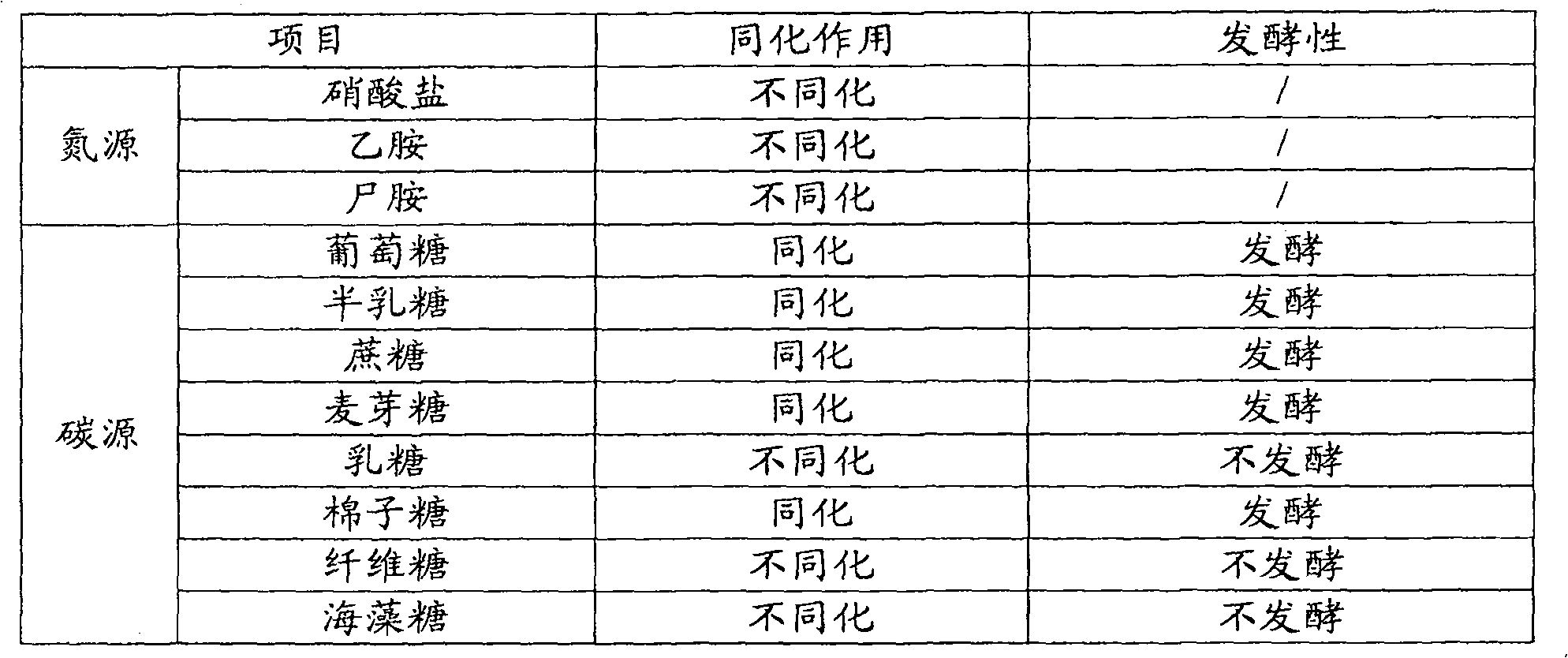

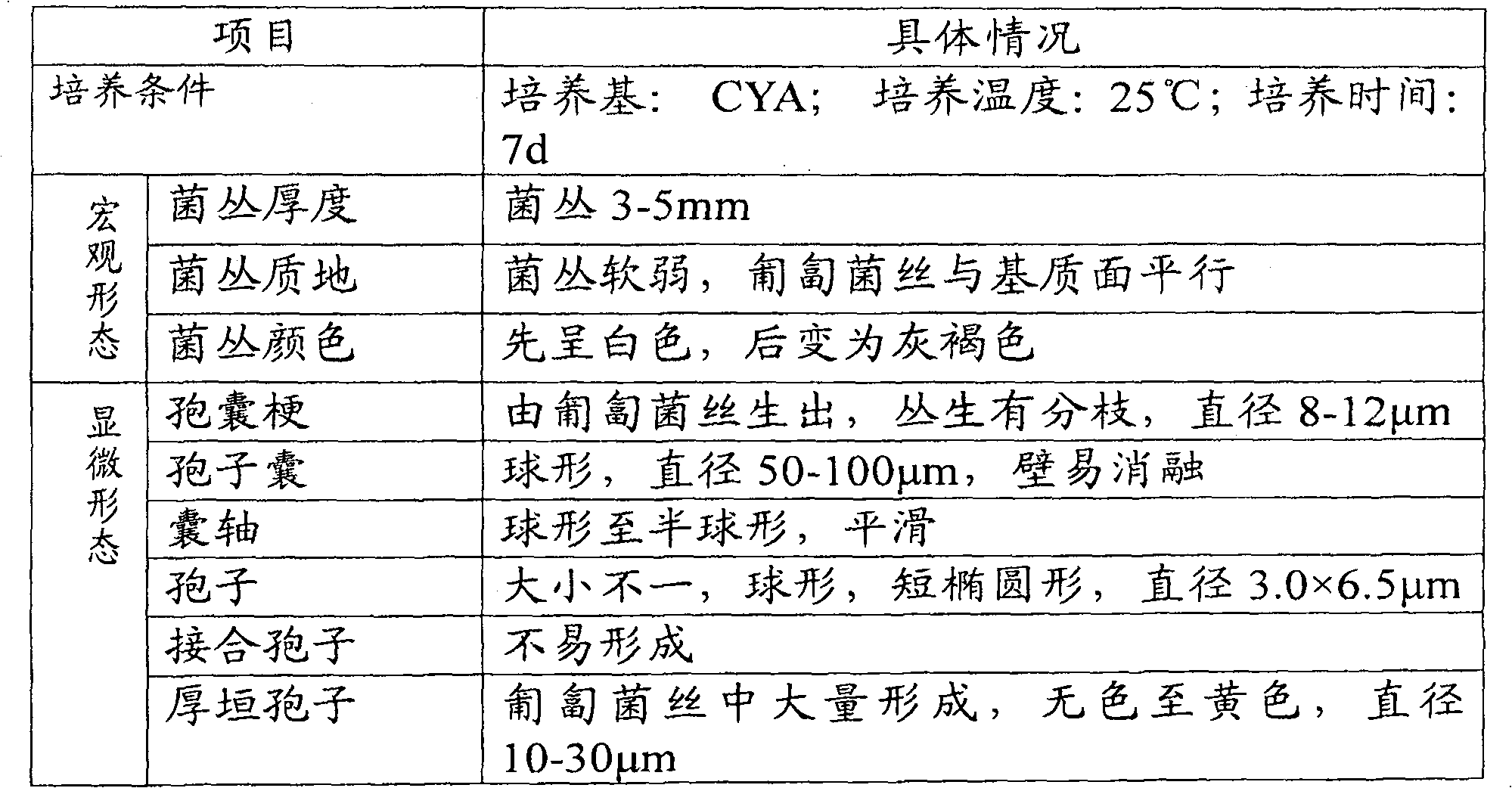

[0167] Example 1 uses Rhizopus A (Rizopus oryzae CCTCC M209191) and yeast 21 (Saccharomyces cerevisiae CCTCC M209190) of the present invention.

[0168] A) Production of finished song

[0169] (1) Expanded culture of yeast strains

[0170] Firstly, the yeast liquid complete medium is prepared, and the components of the yeast liquid complete medium are: 10% sucrose, 2% yeast autodissolving powder, 0.1% potassium dihydrogen phosphate, 0.1% magnesium sulfate, and pH: 4.8.

[0171] Then inoculate, pick a ring of thallus from the yeast slant strain and transfer it into the prepared liquid Erlenmeyer flask, culture on a shaker at 30°C and 200rpm for 36 hours, and centrifugally filter to obtain a yeast filter cake for later use.

[0172] (2) the cultivation of rhizopus bran species

[0173] Prepare 80% water-containing bran, divide into 1000mL triangular flasks, fill each bottle with 150g, sterilize at 121°C, 0.1MPa, and sterilize for 40 minutes; take it out and cool it for later u...

Embodiment 2

[0184] Example 2 uses Rhizopus A (Rizopus oryzae CCTCC M209191) and yeast 21 (Saccharomyces cerevisiae CCTCC M209190) of the present invention.

[0185] A) Production of finished song

[0186] (1) Expanded culture of yeast strains

[0187] First prepare the complete yeast liquid medium, then inoculate, pick a ring of bacteria from the yeast slant and put it into the prepared liquid Erlenmeyer flask, culture it on a shaking table at 29°C and 200rpm for 48 hours, and centrifugally filter to get the yeast filter cake for later use .

[0188] (2) the cultivation of rhizopus bran species

[0189] Prepare 75% water-containing bran, divide into 1000mL triangular flasks, fill each bottle with 165g, sterilize at 121°C, 0.1MPa, and sterilize for 50 minutes; take it out and cool it for later use; then insert the original bran seed into the sterilized culture In the medium, each Erlenmeyer flask received 6 slices and placed in a 28°C incubator for 72 hours.

[0190] (3) Preparation of...

Embodiment 3

[0198] Except adopting rhizopus B, yeast 23, A) the production of finished song and B) the brewing of rice wine are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com