Process for producing 20-denier and 1-pore semi-dull fully-drawn fibers of nylon 6

A production process and semi-extinction technology, which is used in fiber processing, complete sets of equipment for the production of artificial threads, and stretching and spinning methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, production technique of the present invention

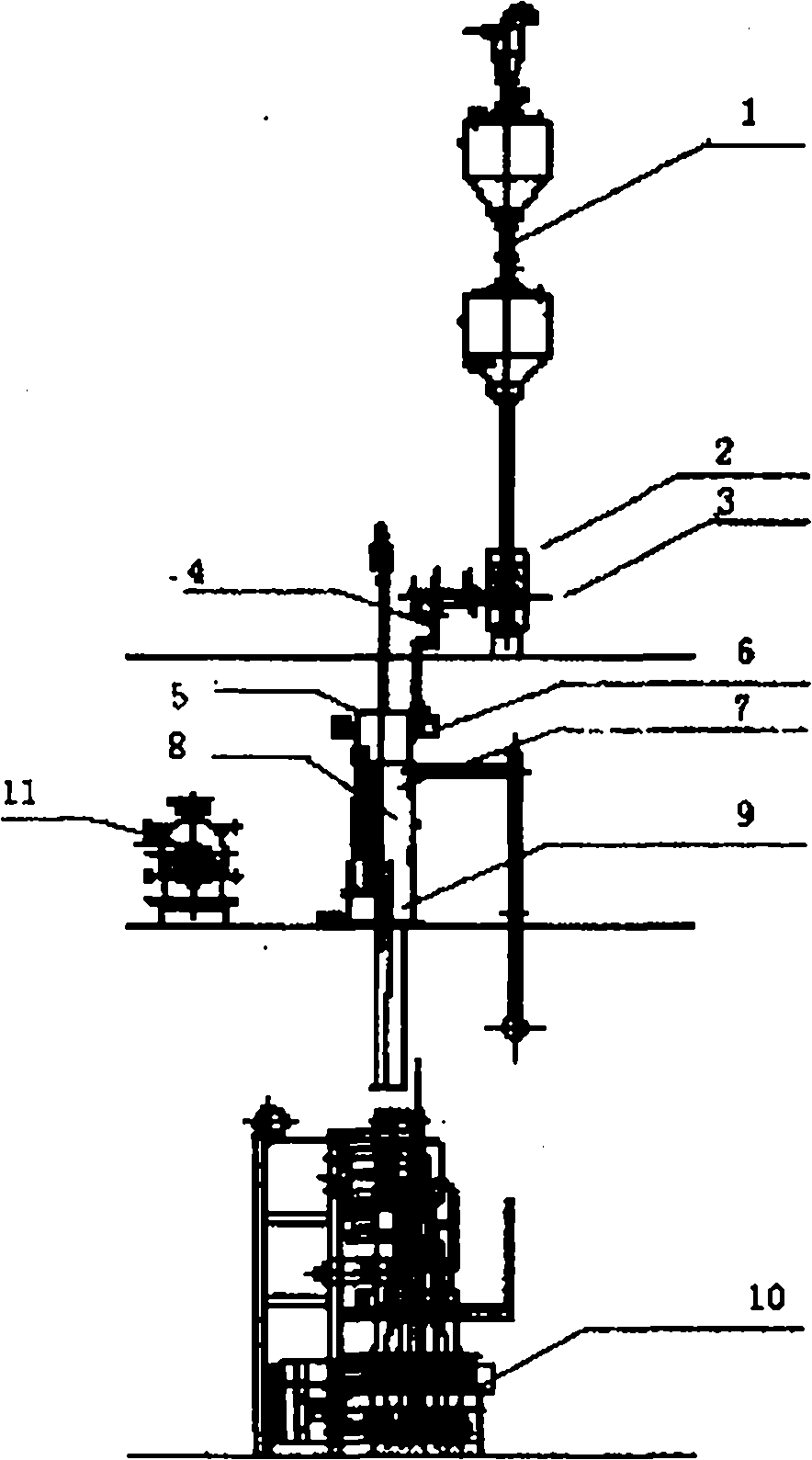

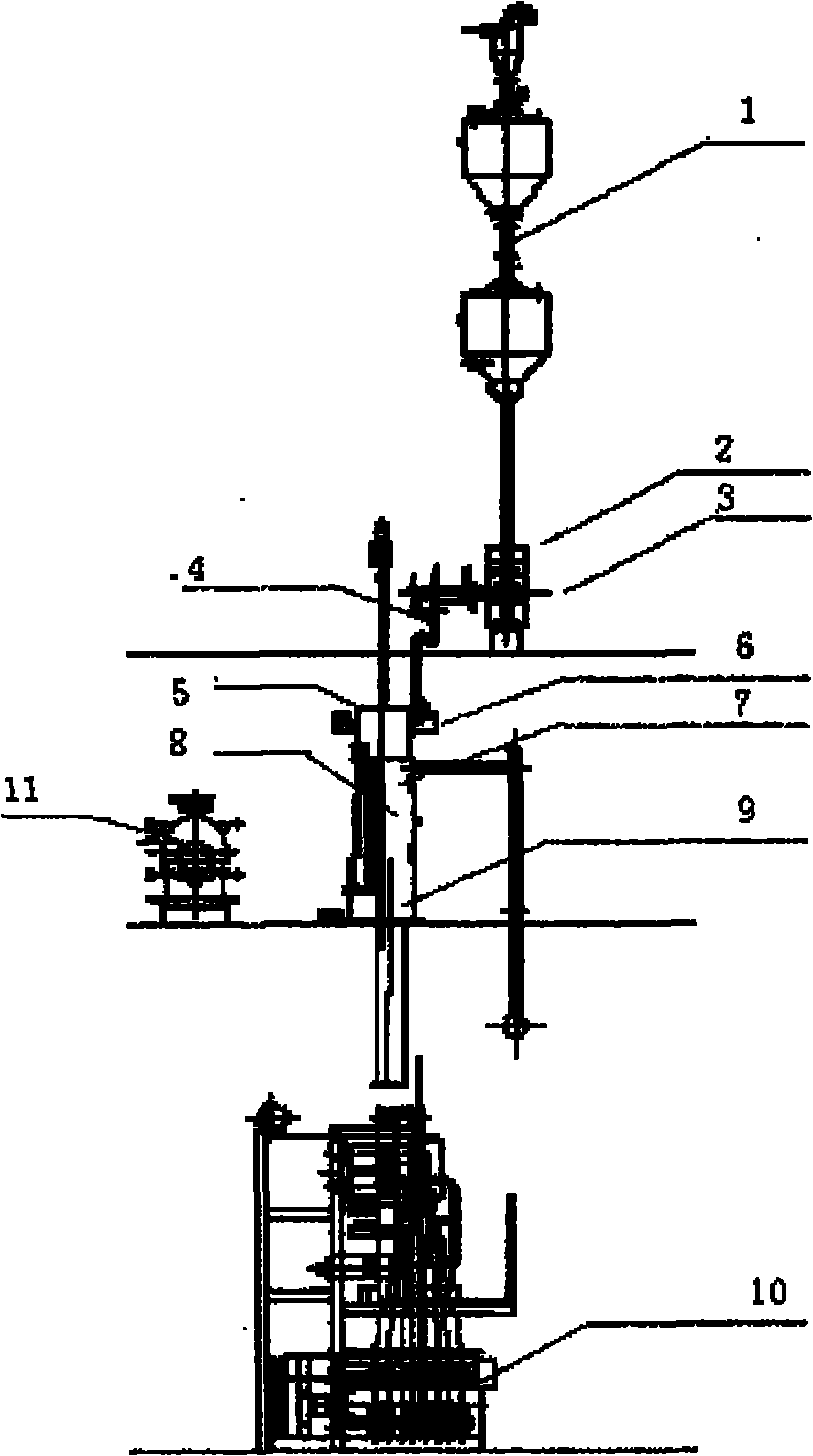

[0032] 20 denier nylon 6 semi-dull fully drawn fiber spinning process, combined with process flow chart for further explanation.

[0033] Spinning equipment and supporting devices, spinning equipment and supporting devices, including: 1. slice conveying, 2. screw extruder, 3. measuring head, 4. melt distribution pipe, 5. spinning box, 6. spinning Silk metering pump, 7. Spinning assembly, 8. Side blowing device, 9. Oiling device, 10. Winding machine and 11. Biphenyl steam generator (see attached drawing for details).

[0034] Process flow: Nylon 6 semi-dull slices enter the screw extruder 2, and are extruded and melted to become a spinnable nylon 6 melt. In the screw extruder 2, there are three temperature control zones, and the heating temperature in the first zone is 250-252°C, the heating temperature in the second zone is 253-258°C, the heating temperature in the third zone is 256-258°C, the nylon 6 melt f...

Embodiment 2

[0036] Embodiment 2, production technique of the present invention

[0037] 1) Nylon 6 slices are heated, extruded, and melted into a melt in a screw extruder with a rotation speed of 40 rpm and a heating temperature of 250-260°C. The screw extruder is divided into three temperature control zones, one The heating temperature of the zone is 250-252°C, the heating temperature of the second zone is 253-258°C, the heating temperature of the third zone is 256-258°C, the temperature of the nylon 6 melt from the screw extruder is 250-255°C, 2) nylon 6 melt In the melt pipeline, it is insulated by a gas-phase heat medium, and is delivered to the spinning box by a pipeline of equal length outside the box, and is metered by a spinning metering pump. Then the nylon 6 melt is evenly distributed to the spinning assembly through the pipeline in the equal-length box,

[0038] 3) Nylon 6 molten material in the spinning assembly enters the sand cup, and 60 grams of metal sand is loaded,

[0...

Embodiment 3

[0041] Embodiment 3, production technology of the present invention

[0042]Nylon 6 semi-dull slices are heated in the screw extruder 2 with a rotation speed of 40 rpm and a heating temperature of 250-260°C, extruded and melted to become a spinnable nylon 6 melt, and processed in the screw extruder In 2, it is divided into three temperature control zones, the heating temperature of the first zone is 250-252°C, the heating temperature of the second zone is 253-258°C, and the heating temperature of the third zone is 256-258°C. The nylon 6 melt from the screw extruder 2 is passed through Measuring head 3, the temperature of the measuring head is 253°C, the spinning temperature is guaranteed to be 253°C, and then the melt distribution pipe 4 is sent to the spinning metering pump 6 in the spinning box 5 for accurate metering, and the nylon 6 melt is melted by the equal length pipe The melt is evenly distributed into the spinning assembly 7, the spinning metering pump 6 has a supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com