Automatic control system and control method of working device of excavator

An automatic control system and working device technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as difficulty in adapting and complicated control methods, so as to reduce work intensity, save energy, improve work efficiency and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

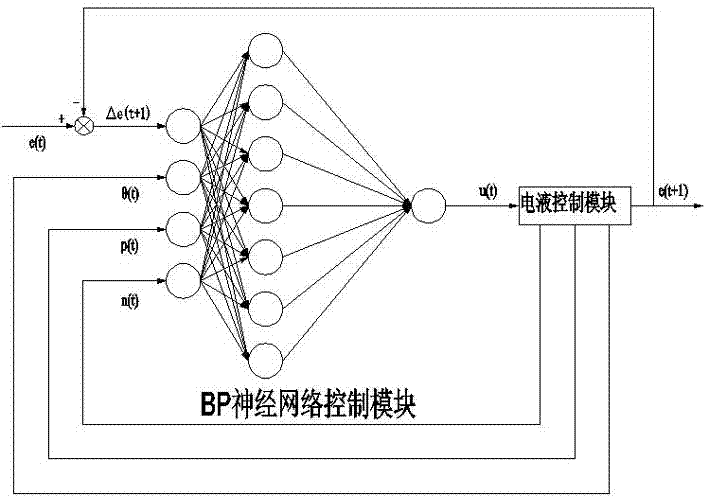

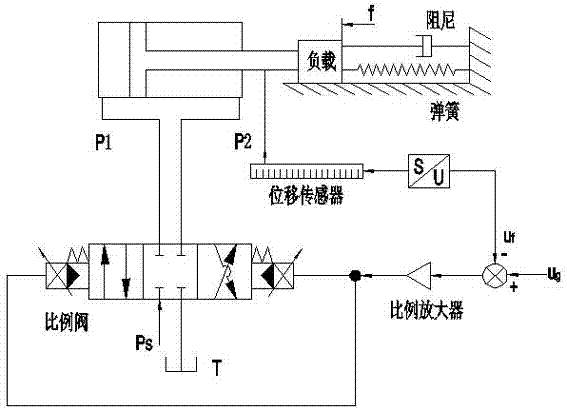

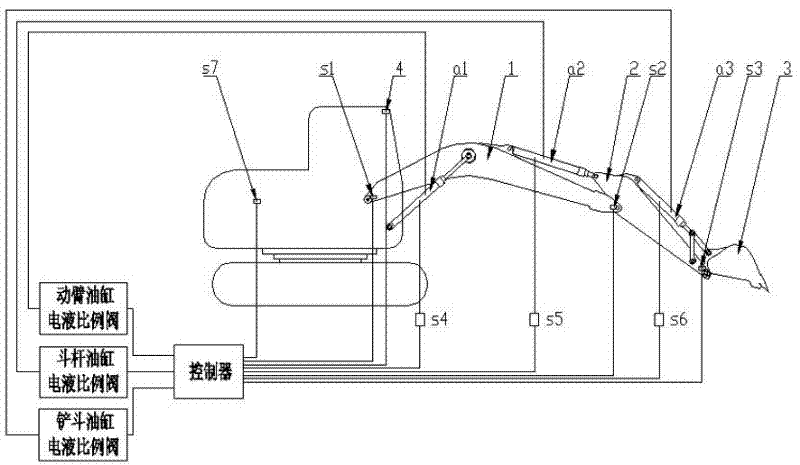

[0026] Embodiment 1: An automatic control system for an excavator working device, comprising: a boom angle sensor, a stick angle sensor, a bucket angle sensor, a boom cylinder pressure sensor, a stick cylinder pressure sensor, a bucket cylinder pressure sensor, Rotational speed sensor, boom cylinder electro-hydraulic proportional valve, stick cylinder electro-hydraulic proportional valve, bucket cylinder electro-hydraulic proportional valve, among them, the programmable controller with software program includes simulated driver control boom, stick, shovel Dou's BP neural network modules c1, c2, c3 and electro-hydraulic control modules c4, c5, c6. The boom, arm and bucket control systems are similar, and the system structure diagram is as follows: figure 1 As shown, the structural diagram of the electro-hydraulic control module is shown in figure 2 shown.

[0027] see image 3 , the device of the present invention includes boom 1, stick 2, bucket 3, boom cylinder a1, stick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com