Thermocompressor driven by linear motors

A technology of thermal compressors and linear motors, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc. It can solve the problems of easy deviation from the central axis of the air gap, unfavorable smooth operation of the compressor, and unstable movement of the compressor, etc. Problems, to achieve the effect of small vibration, force balance, and reduce mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

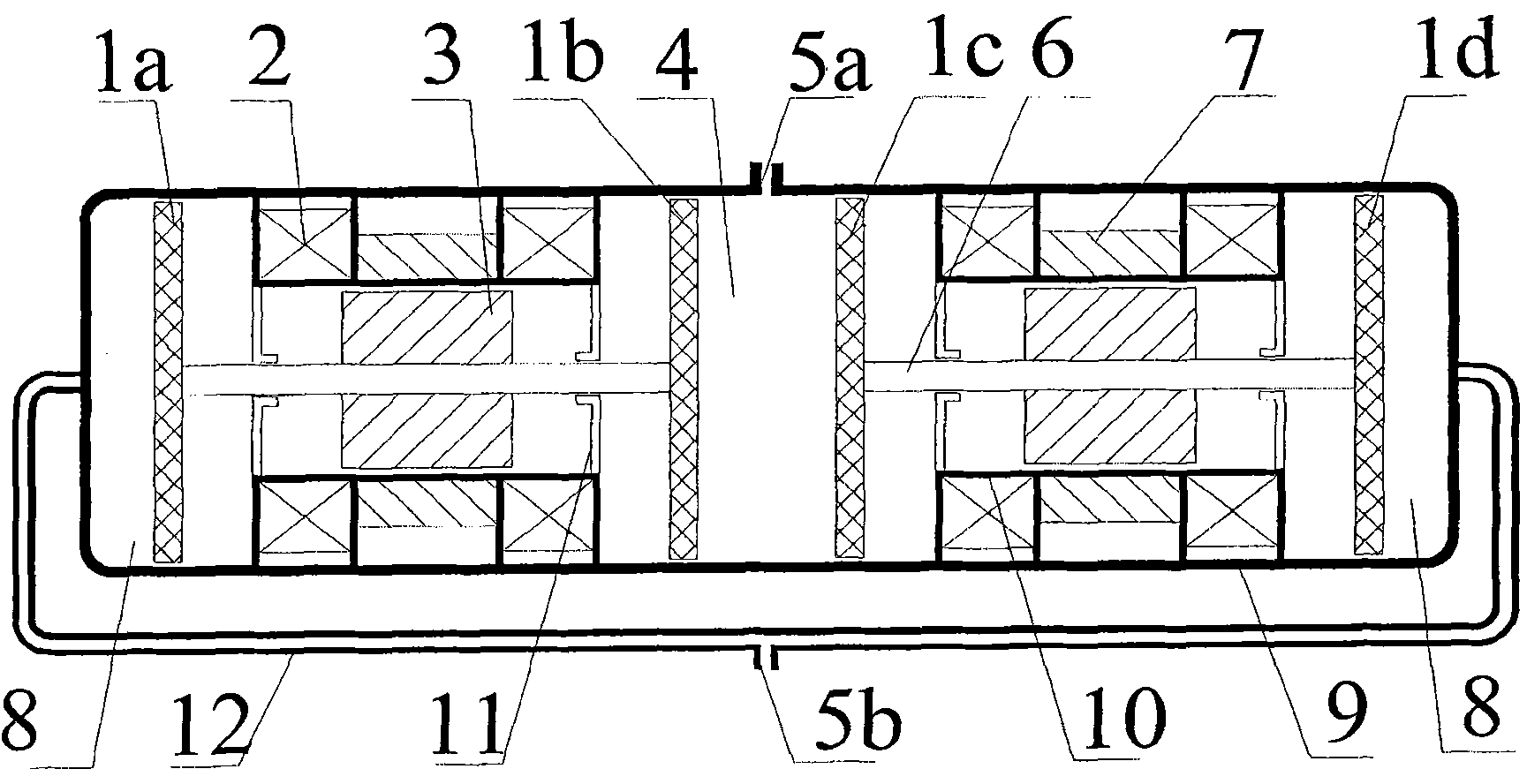

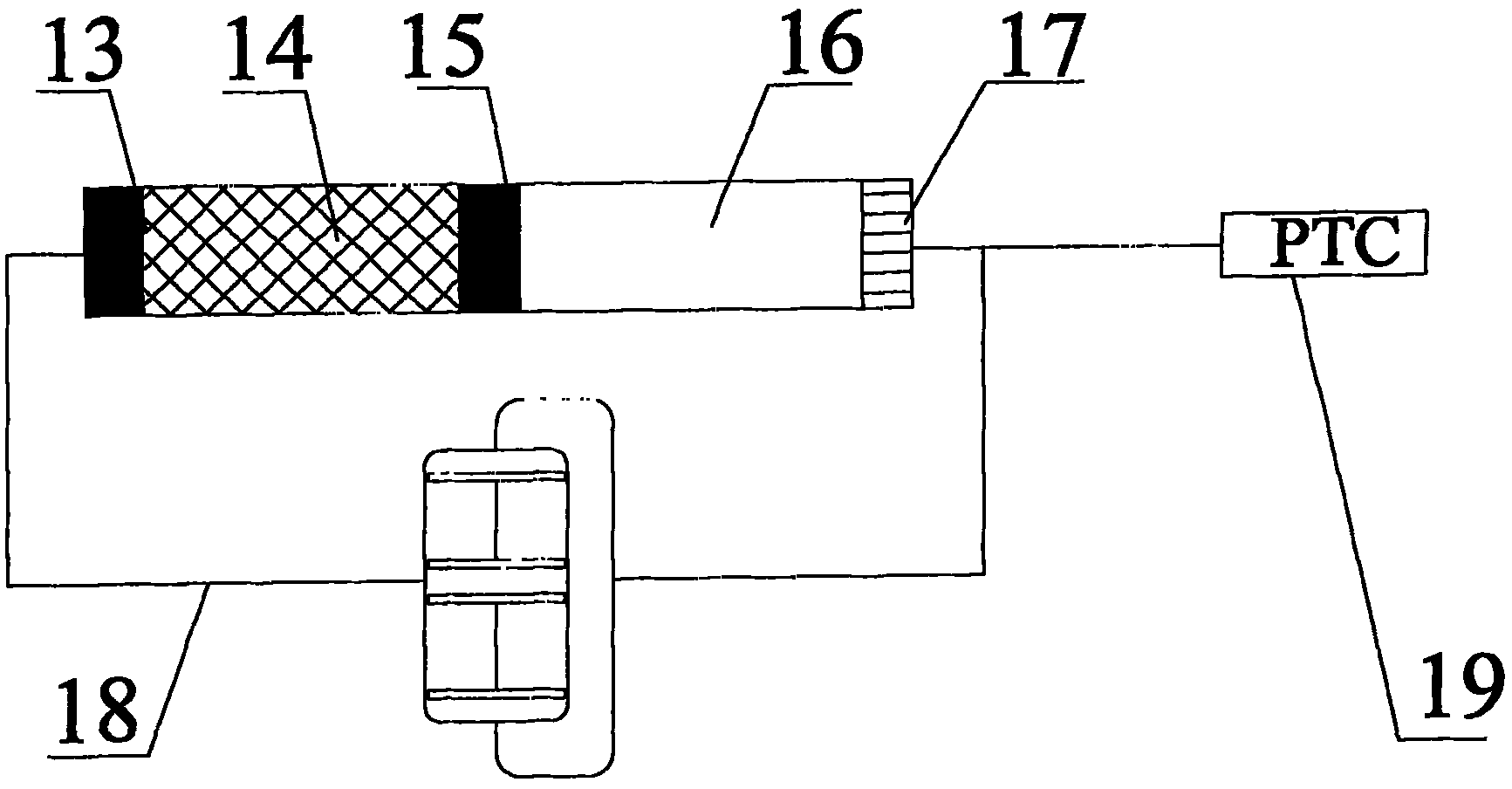

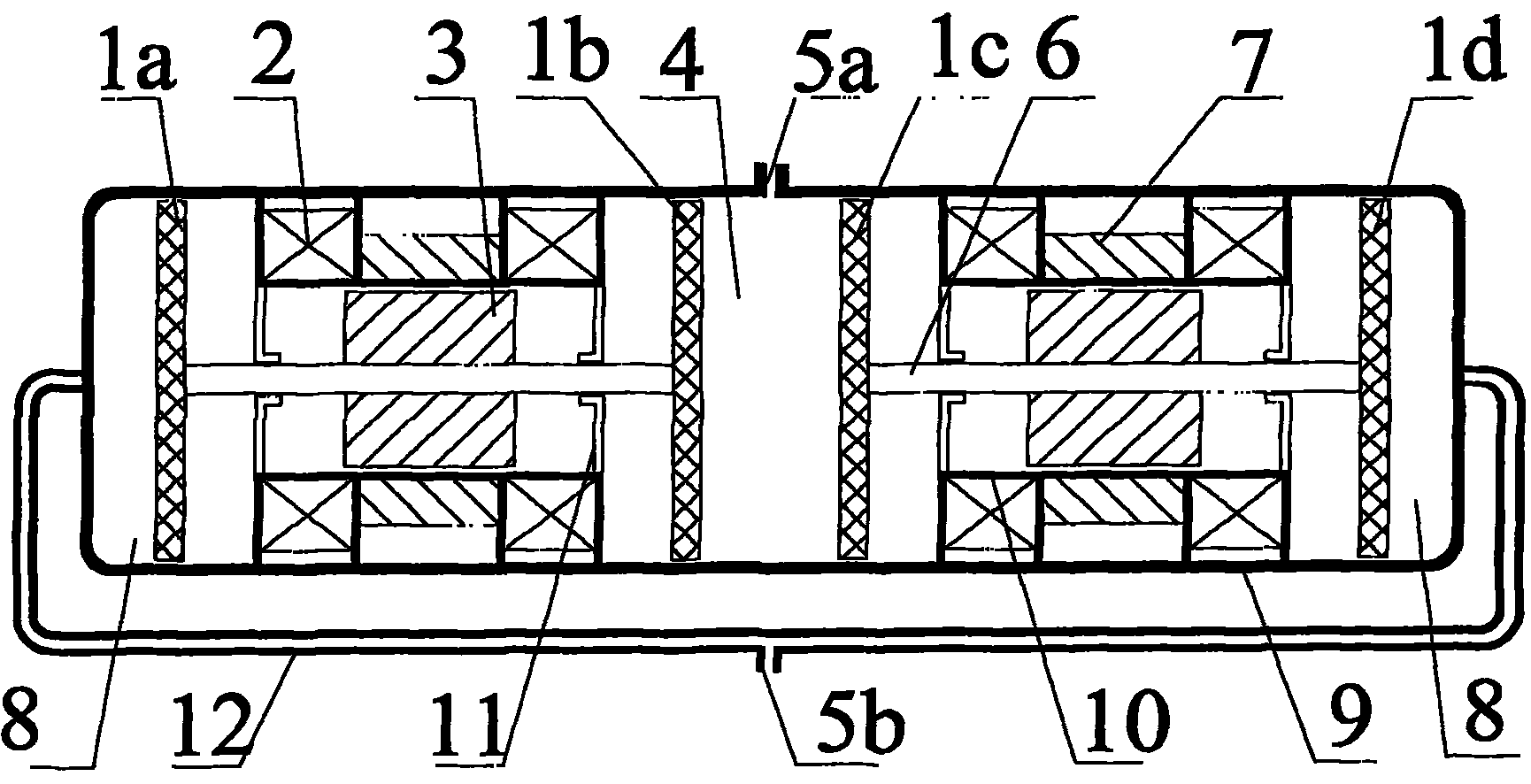

[0017] see figure 1 , which is a schematic diagram showing the structure of the driving unit of the thermal compressor in one embodiment of the present invention. In this embodiment, the linear motor is a moving iron type oscillating motor. As shown in the figure, the drive unit includes a cylinder 9 and a linear motor-piston assembly disposed in the cylinder, wherein two identical linear motor-piston assemblies each having a double-headed piston are symmetrical with respect to the radial center line of the cylinder 9 Arrangement, the piston heads 1b, 1c facing each other of the double-headed pistons of the two linear motor-piston assemblies together with the cylinder wall define the first working chamber 4 in the middle of the cylinder, and the piston heads 1a, 1d away from each other are at the two ends of the cylinder and The cylinder walls together define the second working chamber 8, the first communicating pipe 12 connects both ends of the cylinder wall, the first worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com