Laser thickness measuring device of down-draft sintering material layer

A technology of laser thickness measurement and suction sintering, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of harsh environment, difficult maintenance, maintenance, etc., to reduce the transmission link, reduce the impact of harsh environment, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

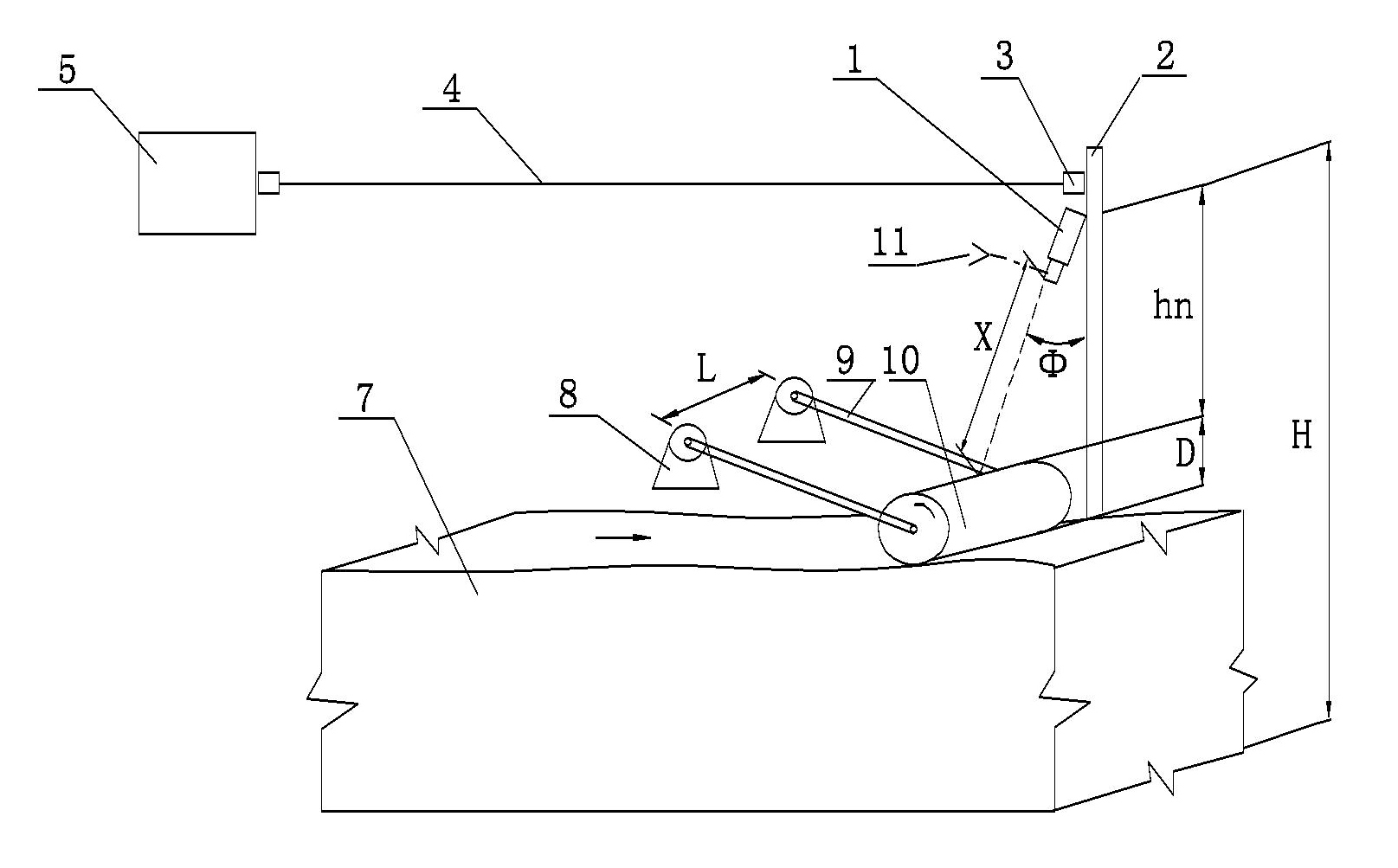

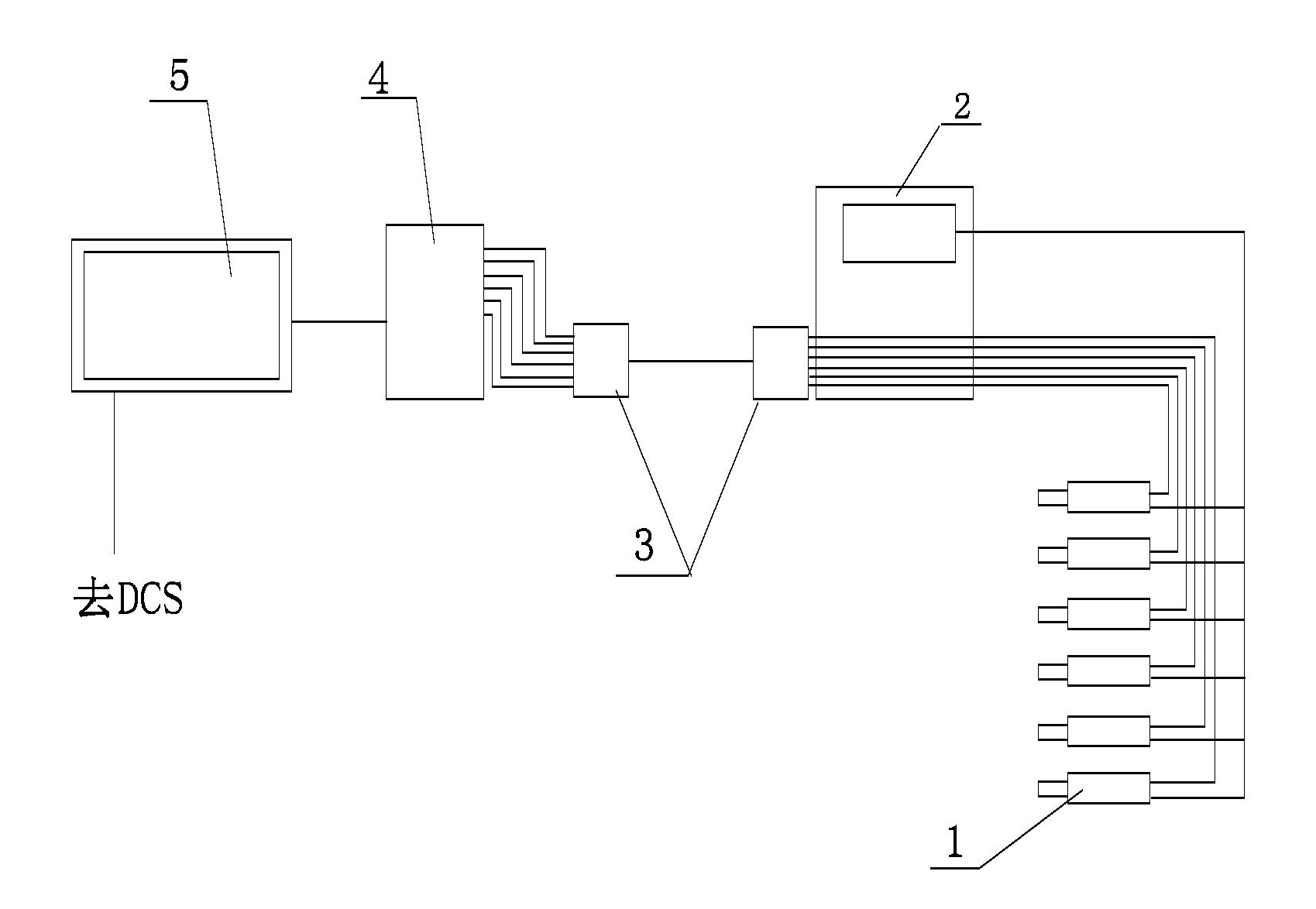

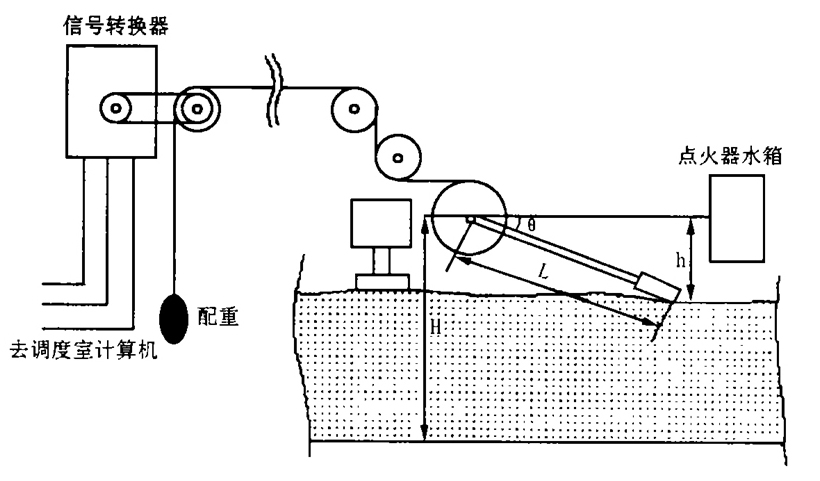

[0024] From figure 1 It can be seen that the present invention has a laser rangefinder 1 , a column 2 , an aviation connector 3 , an industrial computer 5 , a support 8 , a connecting rod 9 , and a counterweight measuring roller 10 . The support 8 and the connecting rod 9 are used to install the counterweight measuring roller 10. One end of the connecting rod 9 is hinged with the support 8, and the other end is rotatably connected with the counterweight measuring roller 10 to form a measuring roller assembly. The installation should be suspended at 100-200mm behind the roller distribution machine at the head of the sintering machine, and the support 8 should be fixed on it. During production, the width of the distribution machine should be matched, and the diameter and weight of the counterweight measuring roller 10 should affect the sintering layer. 7. The surface has a leveling effect, and can continue to roll with the progress of the sintered material. The number of counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com