Method for measuring mixed base concentration by combining pH electrode and flow injection analysis (FIA)

A flow injection, mixed alkali technology, applied in the analysis of materials, analysis by chemical reaction of materials, and material analysis by observing the influence of chemical indicators, etc., can solve problems such as expensive, complicated equipment, and troublesome operation. Achieve the effect of low cost, cheap instrument and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

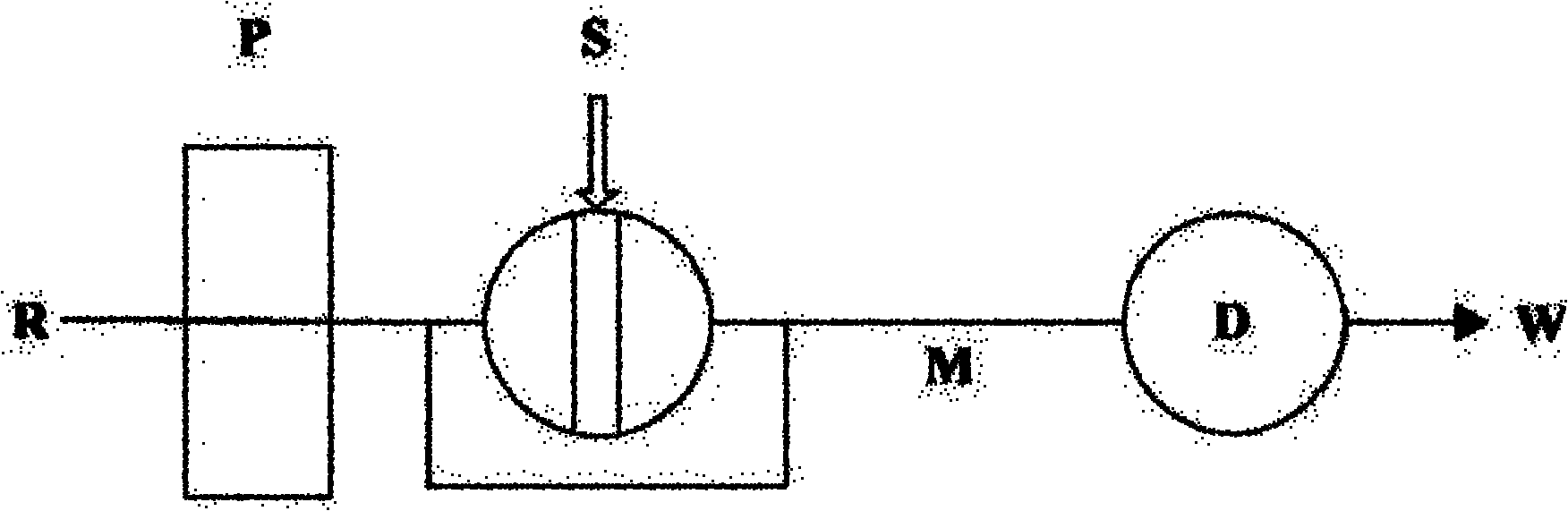

Method used

Image

Examples

Embodiment 1

[0102] Reagent preparation: Take 10mL of filtered industrial wastewater into a 25mL volumetric flask, dilute to the mark with high-purity deionized water;

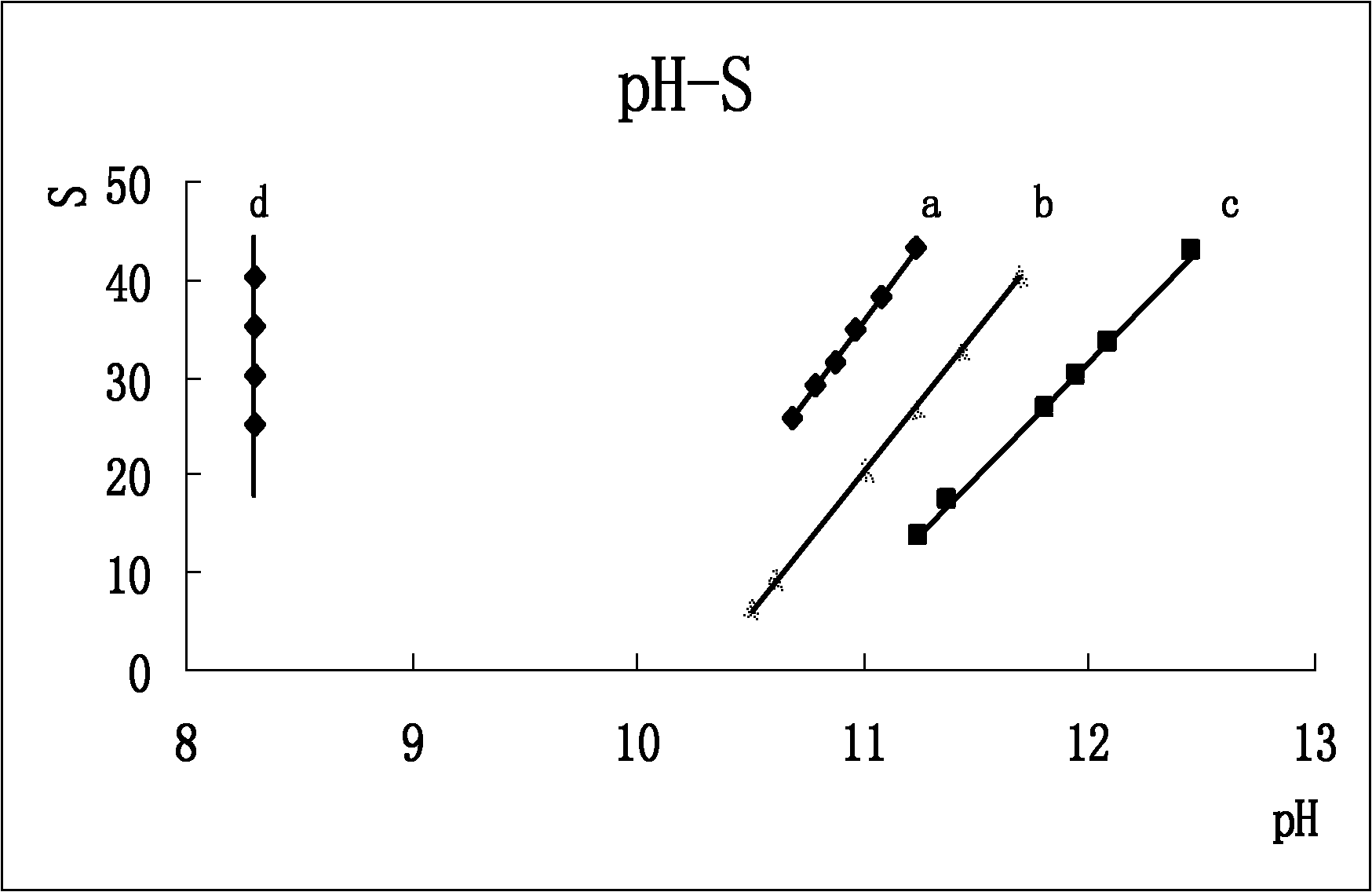

[0103] Experimental method: the pH value of the solution to be measured is 12.22, and then the solution to be tested is injected into the flow injection analysis to obtain the flow injection analysis peak, and the peak area is S=33.95; (12.22, 33.95) is brought into figure 2 In the pH-S coordinate system in , the coordinate point of the solution is between line a and line c, that is, 23.682x-252.42<S<31.25x-307.88, indicating that the solution is a mixed solution of sodium carbonate and sodium hydroxide.

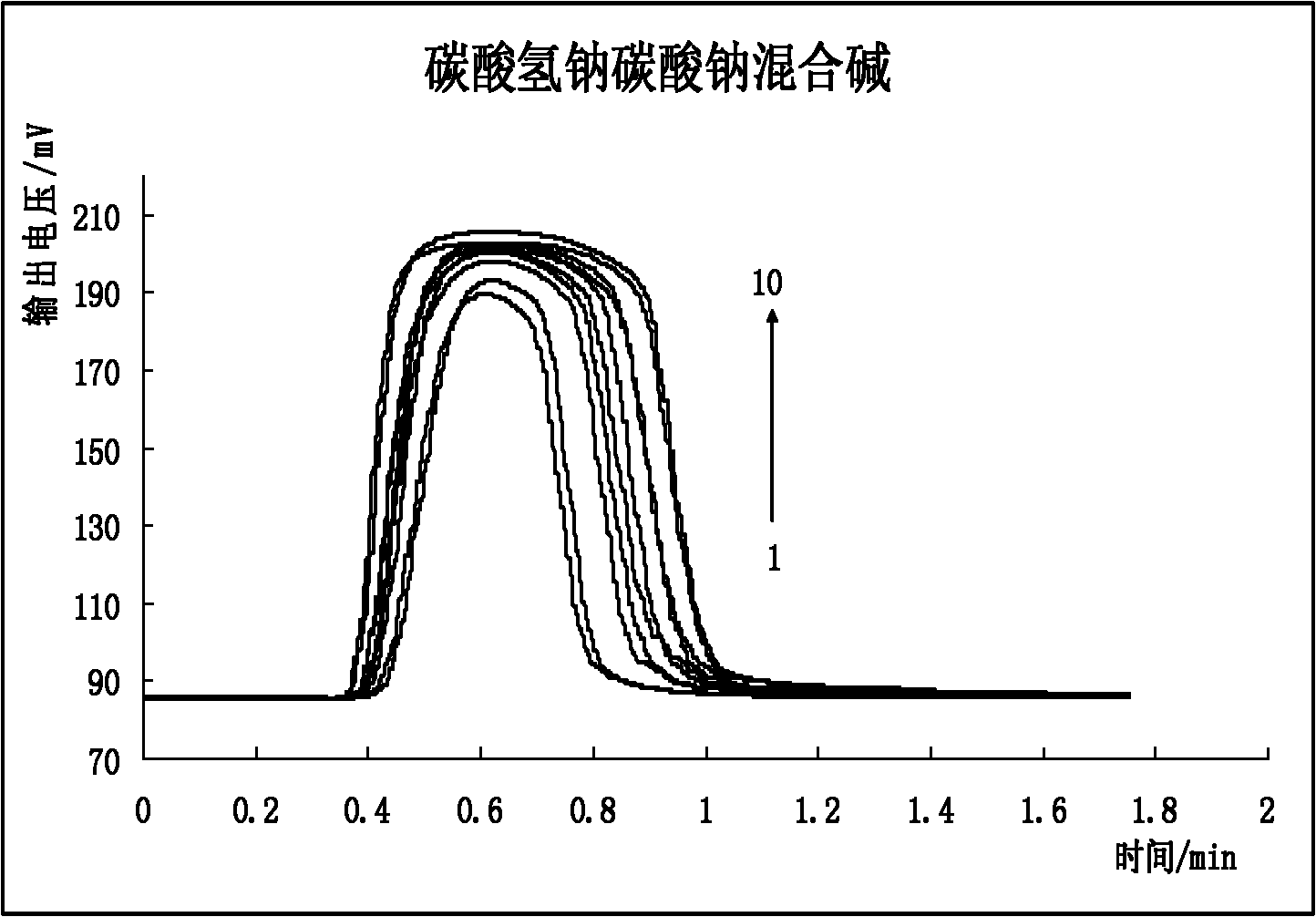

[0104] Use the chromatographic work software to cut out the part of the peak with an output voltage greater than 105mV and the part of the peak with an output voltage greater than 165mV in the FIA peak of the solution to be tested; use the software to integrate the areas of these two part peaks, and the peak areas are ...

Embodiment 2

[0108] Reagent preparation: Take 10mL of boiler water solution No. 1 into a 25mL volumetric flask, and dilute to the mark with high-purity deionized water.

[0109] Experimental method: measure the pH value of the solution to be tested to be 11.63, then inject the solution into the flow injection analysis to obtain the flow injection analysis peak, and the peak area is S=34.47. Put (11.63, 34.47) into figure 2 In the pH-S coordinate system in , the coordinate point of the solution is between line a and line c, that is, 23.682x-252.42<S<31.25x-307.88, indicating that the boiler water is composed of sodium carbonate and sodium hydroxide.

[0110] Use the chromatographic software to cut out some peaks with an output voltage greater than 105mV and some peaks with an output voltage greater than 165mV in the FIA peak of the solution to be tested. Integrate the area of these two partial peaks with chromatographic work software, peak area is respectively S1=46.61 and S2=16.82, p...

Embodiment 3

[0114] Reagent preparation: Take 10mL of the No. 2 boiler water solution into a 25mL volumetric flask, and dilute to the mark with high-purity deionized water.

[0115] Experimental method: the pH value of the solution to be determined is 10.87, and then the solution is injected into the flow injection analysis to obtain the flow injection analysis peak, and the peak area is S=36.06. Bring (10.87, 36.06) into figure 2 In the pH-S coordinate system in , the coordinate point of the mixed alkali is between line a and line d, that is, S > 31.25x-307.88, and X > 8.3, indicating that the components of the solution are sodium carbonate and sodium bicarbonate.

[0116] Use the chromatographic software to cut out some peaks with an output voltage greater than 105mV and some peaks with an output voltage greater than 165mV in the FIA peak of the mixed alkali solution. Integrate the areas of these two partial peaks with the chromatographic work software, and the peak areas are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com