Steel for heat treatment

A quality and element technology, applied in the field of high-strength and high-toughness heat-treated steel, can solve the problems of difficult heat-treated steel, complicated manufacturing process, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] Next, the effects of the present invention will be described by comparing Examples satisfying the requirements of the present invention with Comparative Examples not satisfying the requirements of the present invention.

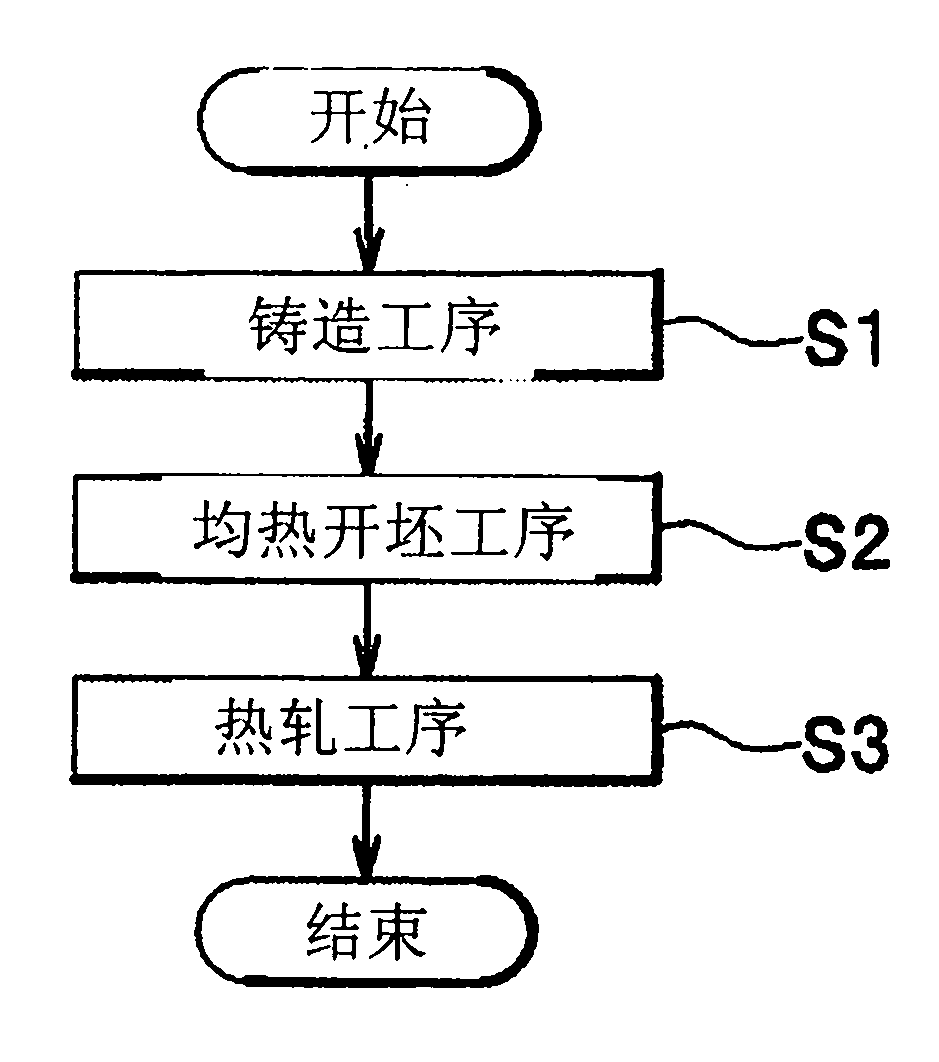

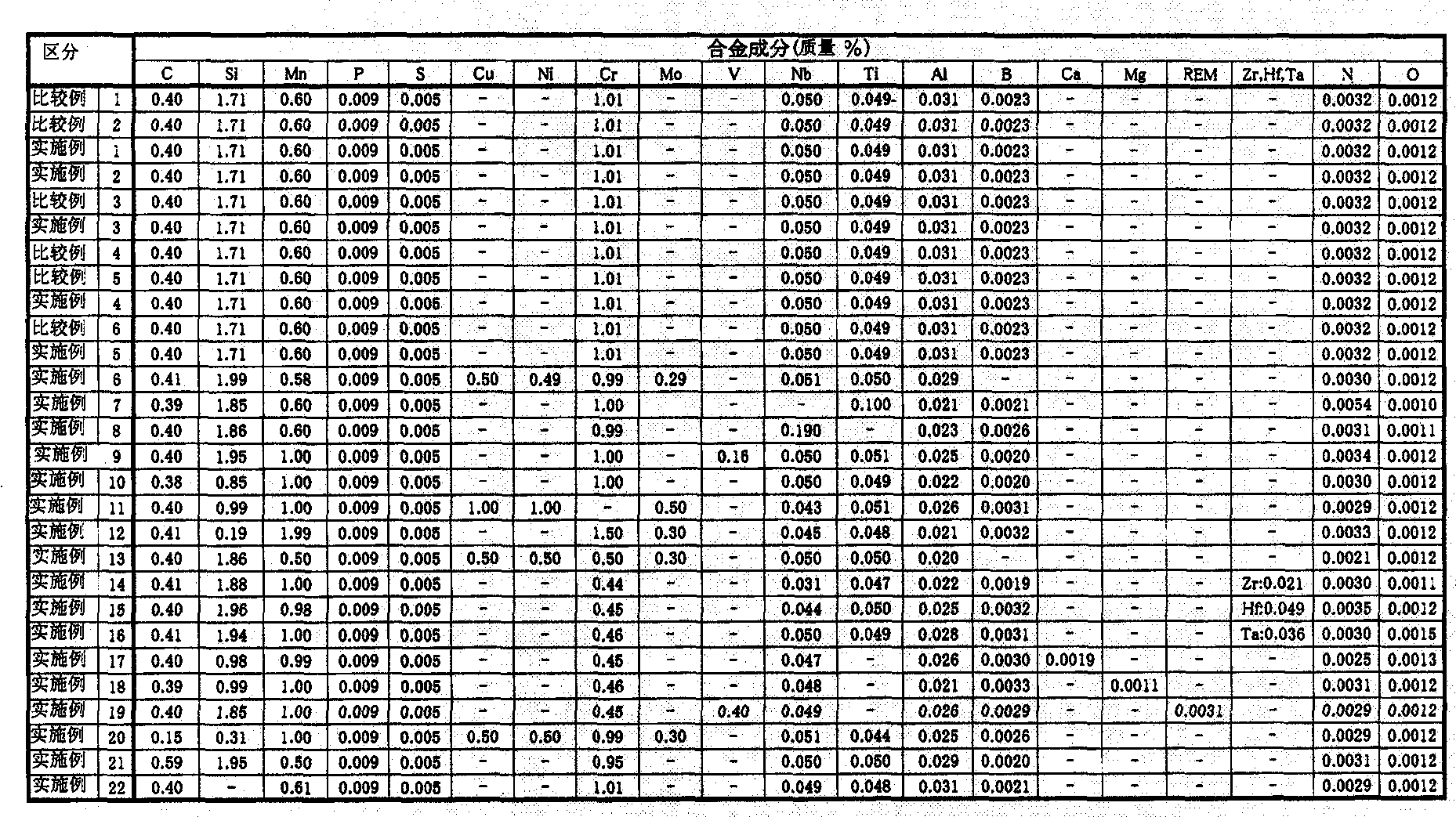

[0114] First, the alloy composition shown in Table 1 was melted in a small melting furnace, cast, soaked and hot-rolled under the conditions shown in Table 2, and the thickness 16 of Examples 1-22 and Comparative Examples 1-6 were obtained. billet. Quenching and tempering (heat treatment) were performed under the conditions shown in Table 2 using these billets.

[0115] [Table 1]

[0116]

[0117] [Table 2]

[0118]

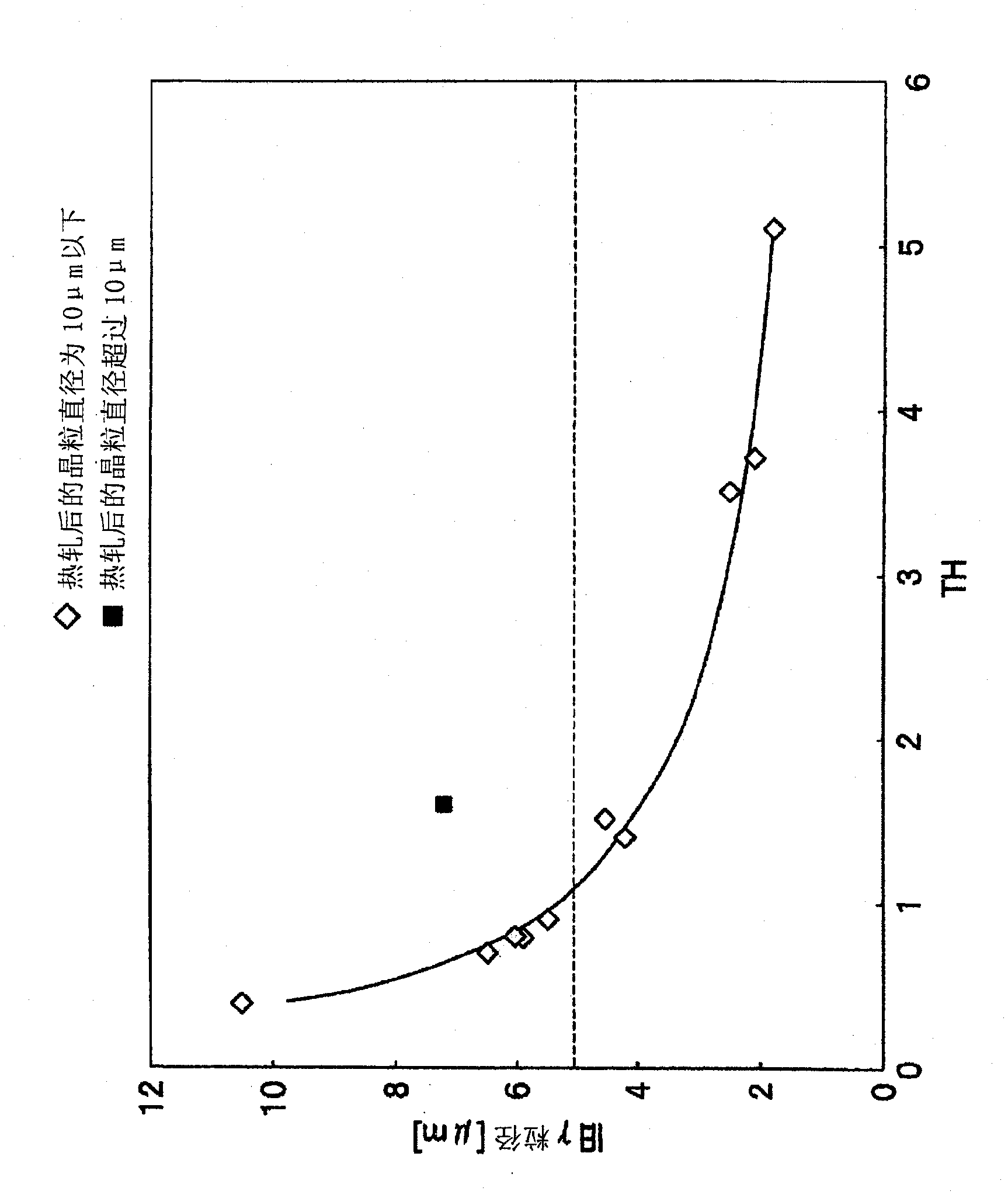

[0119] For the steel slabs of Examples 1 to 22 and Comparative Examples 1 to 6 produced under the conditions shown in Table 1 and Table 2, the value TH (amount of Ti and Nb contained in precipitates of 5 to 100 nm) after hot rolling was evaluated. ), grain diameter (μm) and hardness Hv. In addition, the steel properties of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com