Wallboard materials incorporating a microparticle matrix

A technology of matrix materials and wallboards, applied in building materials, ceramic products, thermal insulation, etc., can solve problems such as unusable and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0148] Example 1 - Testing of Practical Materials of Floating Beads and Sodium Silicate

[0149] The Extendospheres TM A mixture of floating beads in the form is combined with the sodium silicate and allowed to dry and form a fire barrier material. Extendospheres with a diameter size range of 300-600 microns were combined with a sodium silicate solution (Type O from PQ Corporation) in a 1:1 weight ratio. Inject the wet slurry into the cavity around the turbine and allow to dry. which form Extendospheres TM and lumps of sodium silicate. The material was tested using an Ipro-Tek single shaft gas turbine. Tests have shown that the material has high insulation and heat resistance. The barrier is exposed to temperatures up to 1200°C. However, it was found that when the material was directly exposed to the flame for a period of more than a few minutes, the material cracked and blistered and began to lose physical strength.

example 2

[0150] Example 2 - Formation of molds to form wall panels

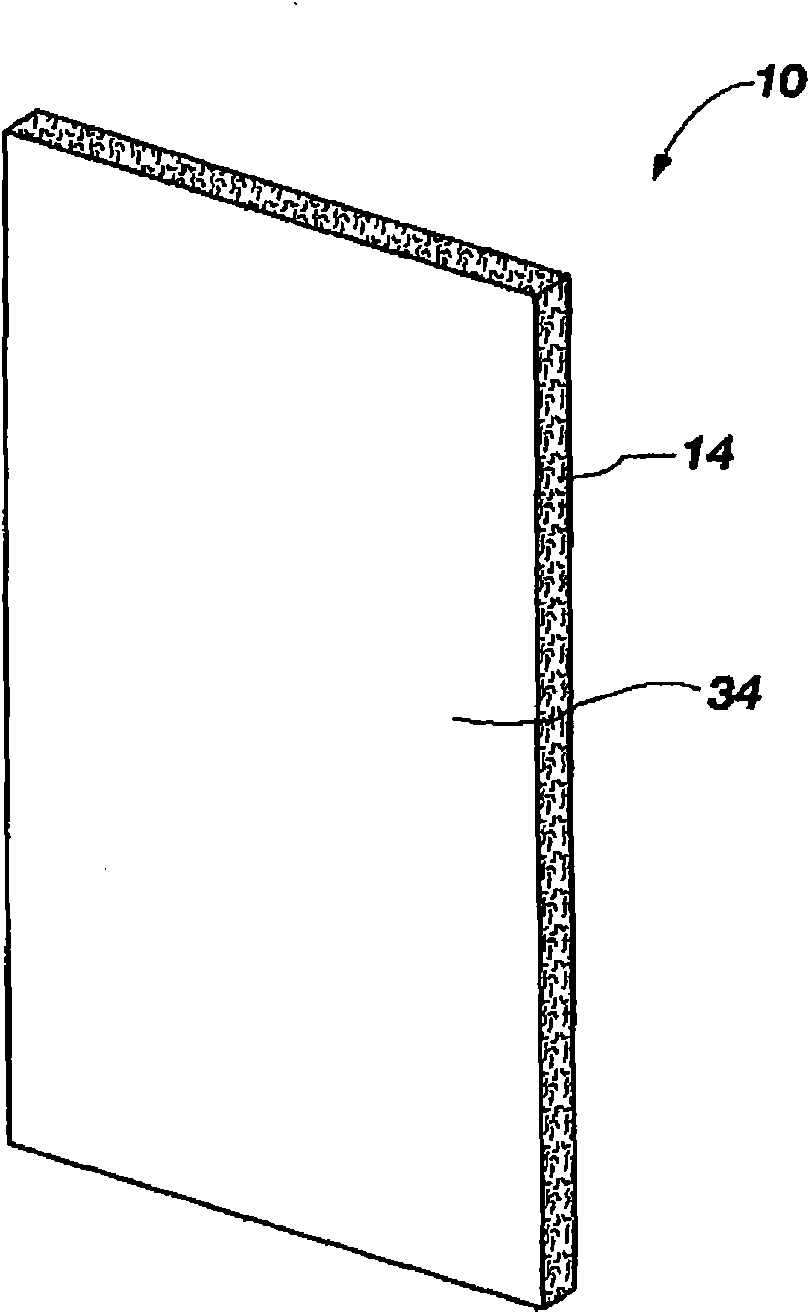

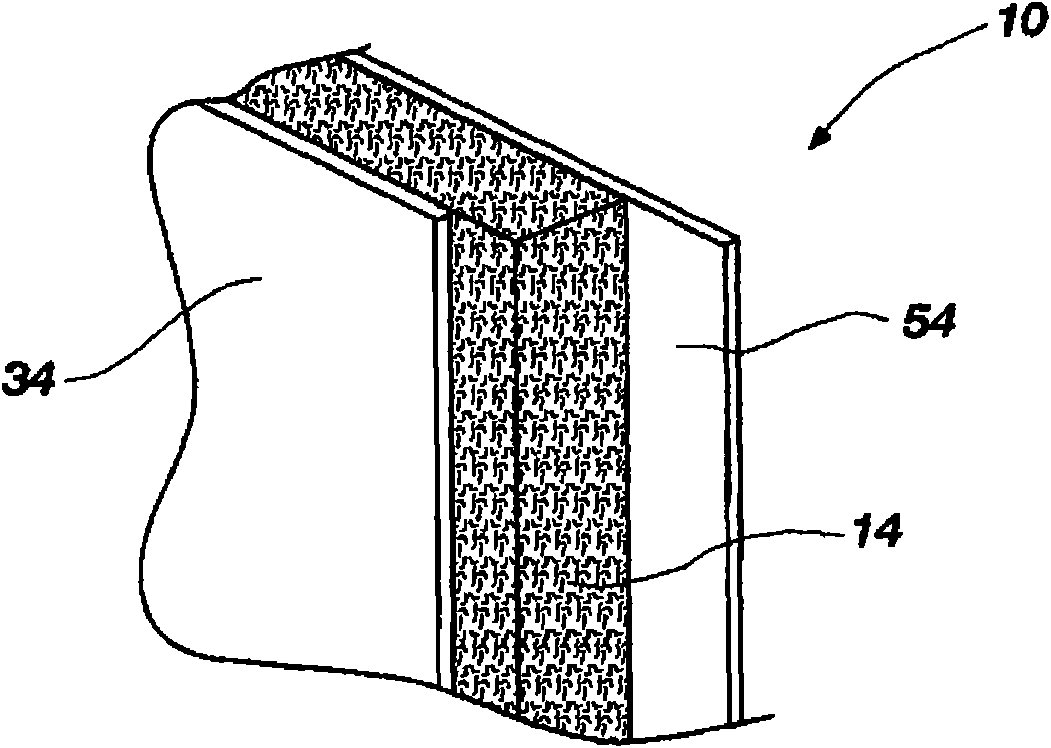

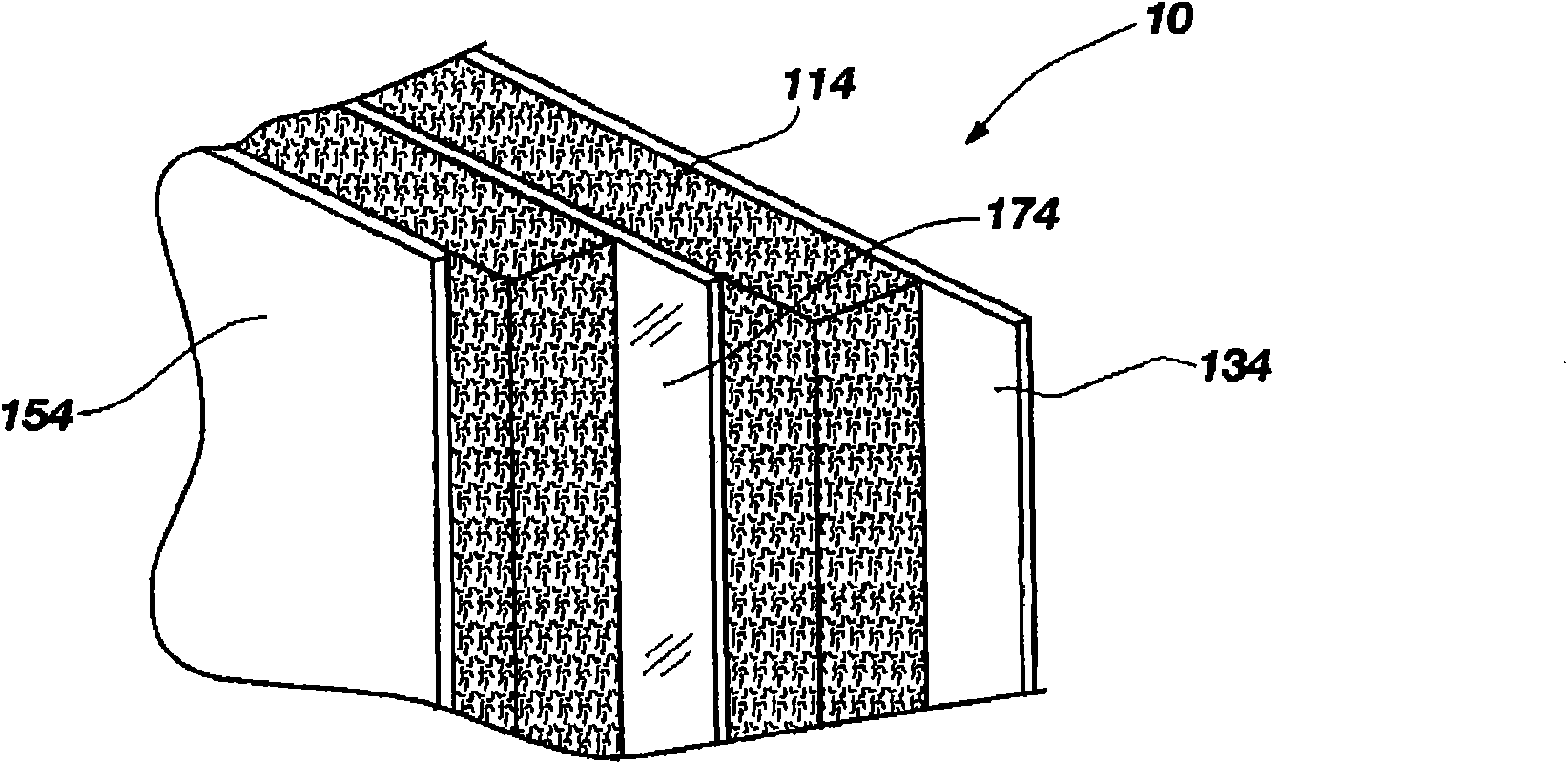

[0151] In one aspect, the utility material can be a wallboard panel. Panels can optionally be formed by exposing uncured wallboard to microwaves. Such formation, as well as formation of normal wall panels, may utilize molds. An example of a mold may consist of a vinyl ester resin mold having a top member and a bottom member. To form the vinyl ester resin mold a wooden form is first built. Wooden formwork can be based on such as Figure 16 shapes and sizes shown.

[0152] To form the vinyl ester resin mold, an outer wood form was attached to the wood form base using double sided tape. Any releasable adhesive or attachment structure may alternatively be used. The resin mixture was formed from 97.5 wt% vinyl ester resin mixed with 2.5 wt% methyl ethyl ketone peroxide (MEKP) catalyst. Beads in the form of Extendospheres and the resin mixture were added in a 1:1 ratio to form the core mixture. Use a mixing device...

example 3

[0153] Example 3 - Preparation of Wall Panels Using Molds

[0154] As noted above, the form of the utility material may be a wallboard panel. The panels can optionally be formed by using porous vinyl ester resin molds. First, use the Figure 17 The backing template shown cuts out the wallboard backing. Although a particular backing paper shape is shown, it should be understood that the backing paper may be of any shape or size sufficient to form a section of wallboard. Cut the facing paper into a larger rectangle that is just smaller than the backing paper. In this example, the facing paper was cut into rectangles measuring 11.625 inches by 15.25 inches. Fold the backing paper and place it in the perforated mold. The following materials can be used to form the wallboard compound:

[0155] 700g to 900g microbeads;

[0156] 1100g to 1300g sodium silicate solution, such as that sold as "O";

[0157] 300g to 500g latex binder;

[0158] 20cc to 30cc blowing agent.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com