Electric compressor integral with inverter

A technology for electric compressors and inverters, which is applied to machines/engines, liquid fuel engines, engine components, etc., can solve the problems of inconsistent sealing, difficult to apply sealant, difficult to ensure high-precision sealing, etc., to improve waterproofness. Sex, improve the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

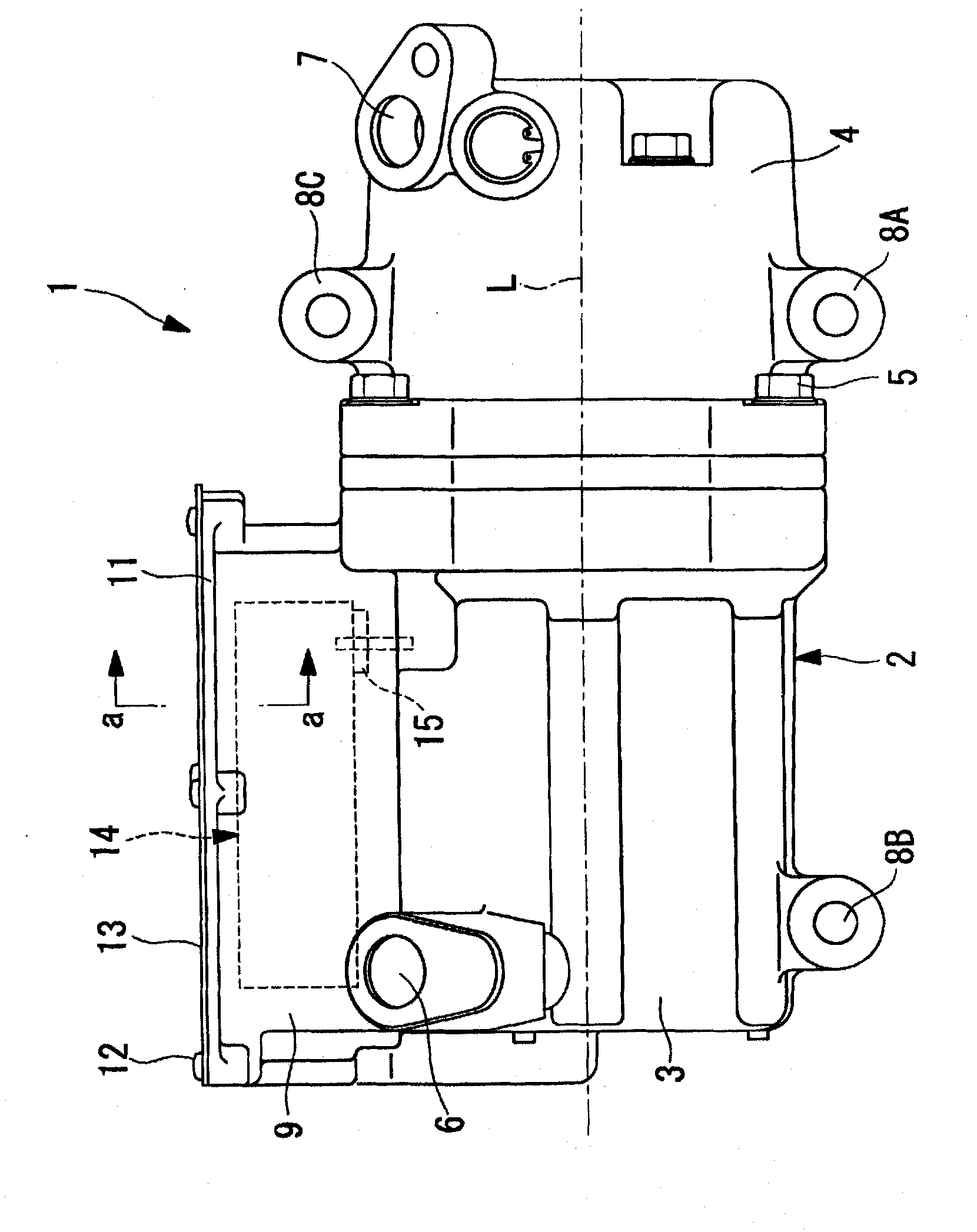

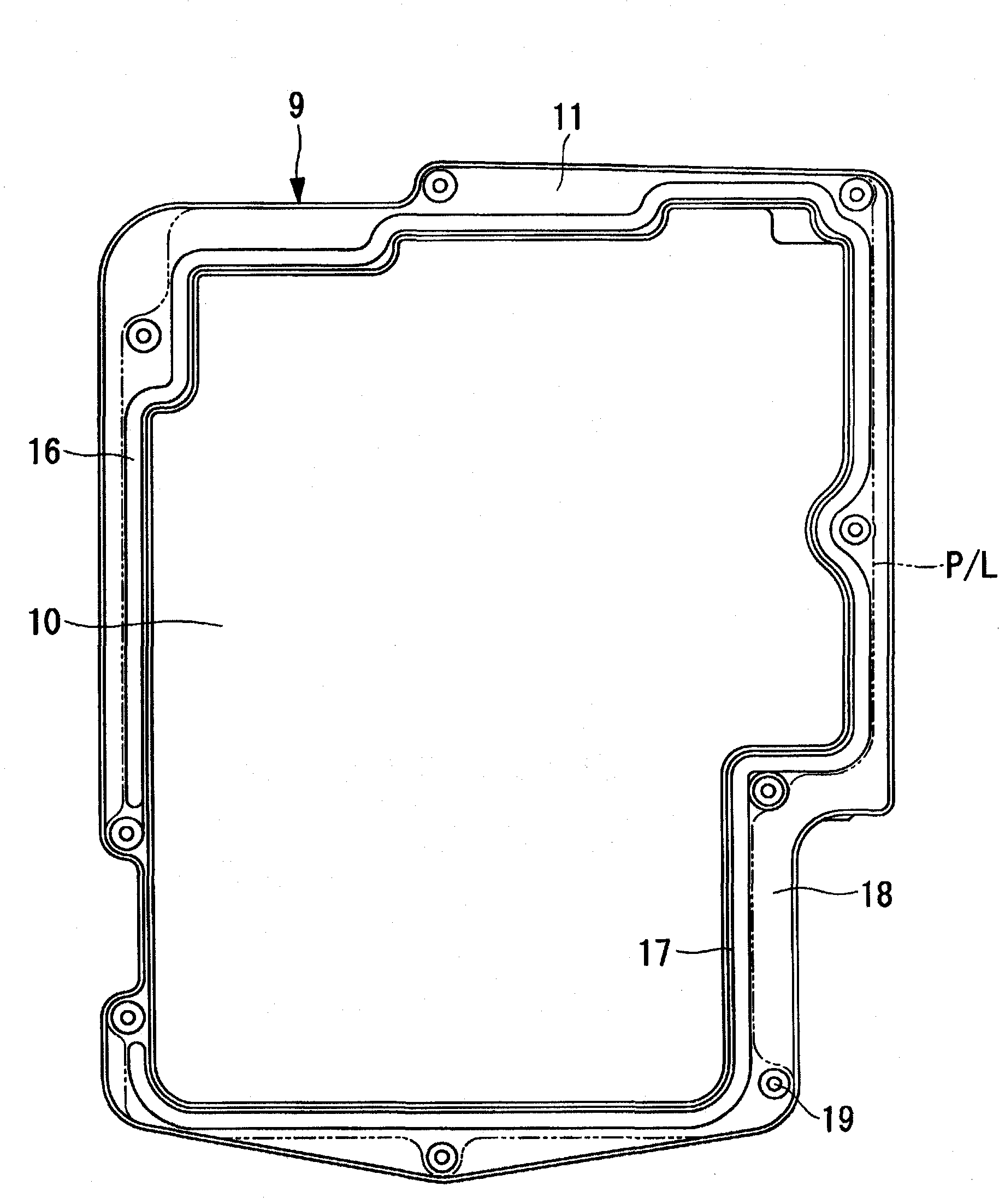

[0036] exist figure 1 shows a side view of the appearance of the inverter-integrated electric compressor related to the first embodiment of the present invention, and figure 2 means with figure 1 The equivalent graph of the a-a profile, in image 3 The middle side shows the end view of the opening side of the converter housing part. The inverter-integrated electric compressor 1 has a casing 2 constituting its outer casing. The housing 2 is constructed by integrally fastening a motor housing 3 and a compressor housing 4 by using bolts 5. The motor housing 3 accommodates a motor not shown in the figure; the compressor housing 4, It accommodates a compression mechanism (not shown). The motor housing 3 and the compressor housing 4 are each made of die-cast aluminum.

[0037] The motor and the compression mechanism built in the casing 2 are connected via a motor shaft, and the compression mechanism is driven by the rotation of the motor. At one end of the motor housing 3 ( ...

no. 2 example

[0053] Next, refer to the attached Figure 5 A second embodiment of the present invention will be described.

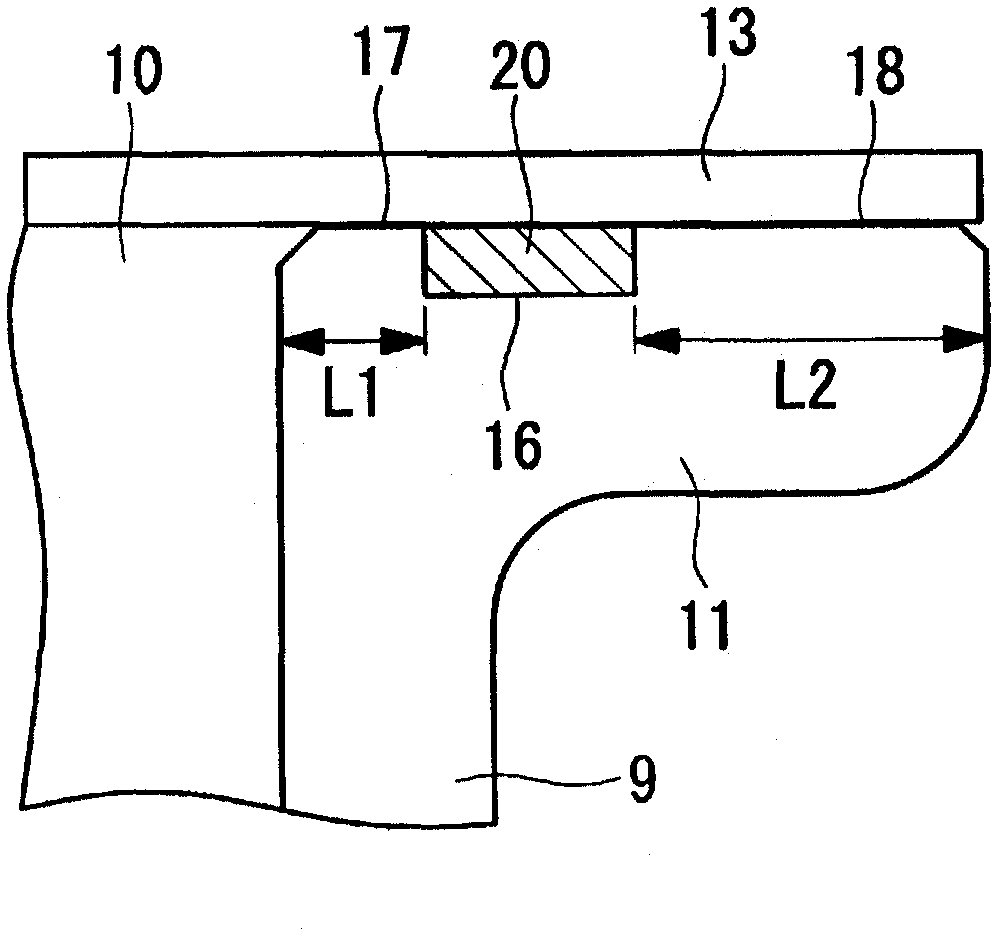

[0054] The difference between the present embodiment and the first embodiment is that a small gap D1 is formed between the joint surface 17 of the flange portion 11 and the cover body 13 . The other points are the same as those of the first embodiment, so explanations are omitted.

[0055] In this example, if Figure 5 As shown, on the flange part 11 of the converter housing part 9, the height of the joint surface 17 formed on the inner peripheral side of the groove 16 is lower than the height of the joint surface 18 formed on the outer peripheral side of the groove 16, so that A small gap D1 is formed between the surface 17 and the cover body 13 . In addition, it is sufficient that the minute gap D1 is about 0.1 mm. exist Figure 5 In , the size of the gap D1 is exaggeratedly enlarged.

[0056] As mentioned above, on the flange portion 11, the height of the joi...

no. 3 example

[0058] Next, refer to the attached Figure 6 A third embodiment of the present invention will be described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com