Tread rubber composite material and preparation method thereof

A technology for tire treads and composite materials, which is applied in the directions of tire treads/tread patterns, special tires, tire parts, etc., can solve the problems such as the difficulty of uniform dispersion of nano-inorganic particles, increase the interfacial force, and the preparation method is simple. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

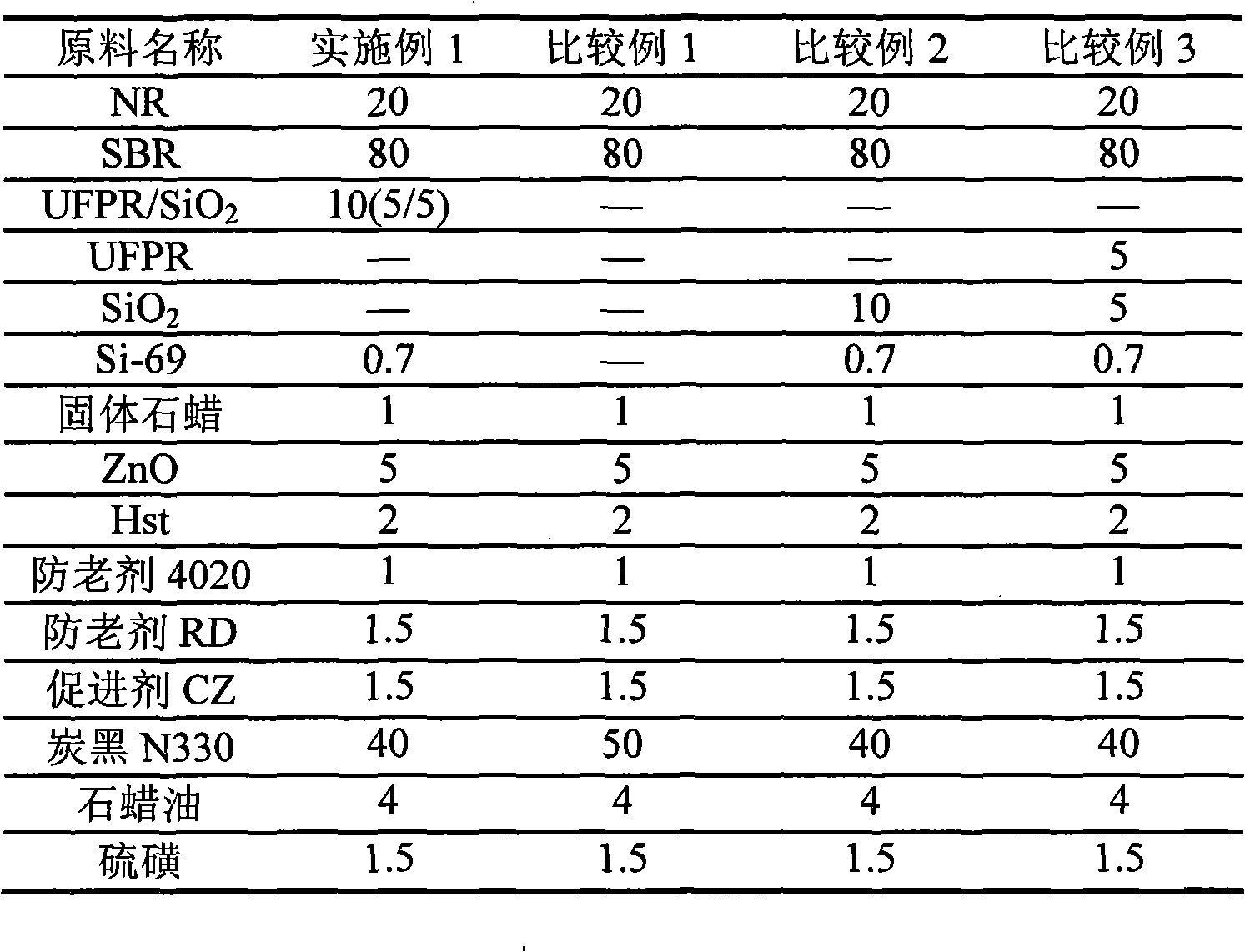

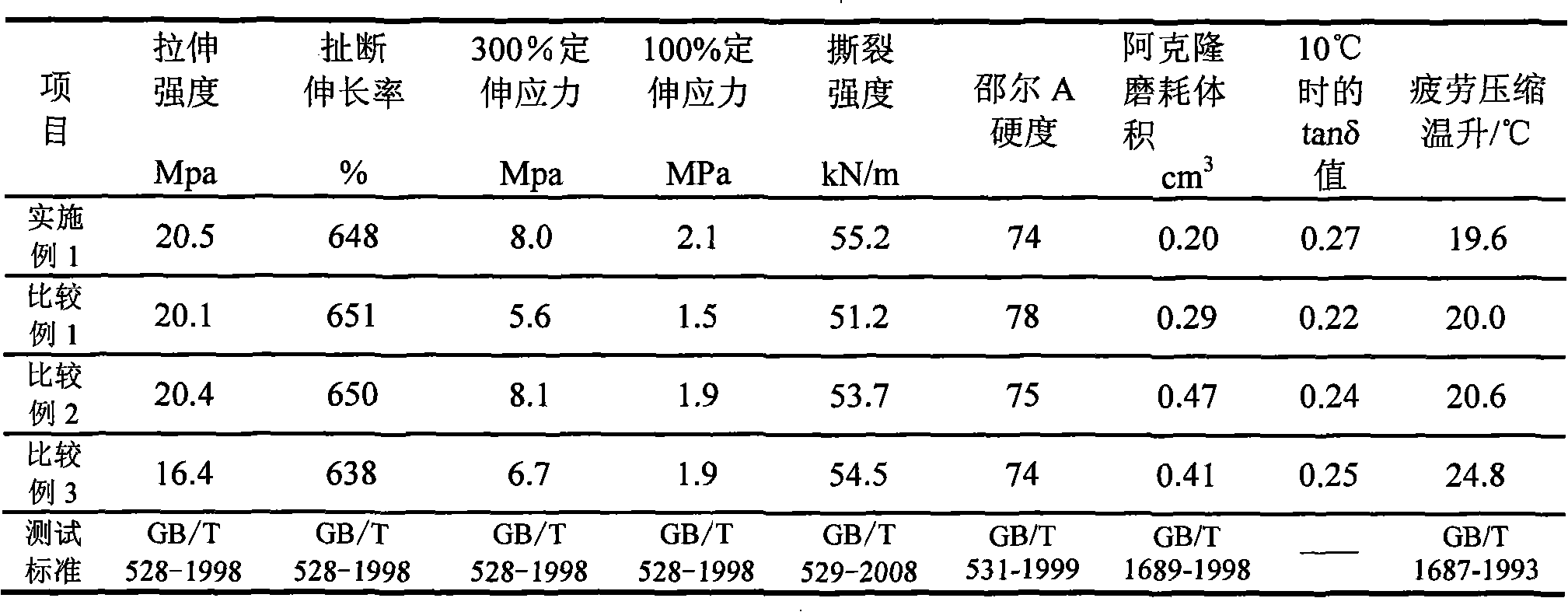

Embodiment 1

[0033] Compound powder preparation:

[0034] The commercially available styrene-butadiene rubber latex (produced by Shanghai Gaoqiao Petrochemical Company, trade name: styrene-butadiene-5050) 4kg with a solid content of 45% by weight is placed in the container, and trimethylolpropane triacrylate 54g is added dropwise under side stirring. , After the dropwise addition is completed, continue stirring for one hour. Then irradiated with a cobalt source at a dose of 0.5 Mrad and a dose rate of 50 Gy / min to obtain an irradiated styrene-butadiene rubber emulsion, wherein the gel content of the rubber particles is 85%, and the average particle size of the particles is 100 nm. The nano-silica (SiO 2 , Shandong Zibo Haina Hi-Tech Materials Co., Ltd., with a particle size range of 20-40nm) mixed with water at a concentration of 5% by weight, dispersed by a high shear disperser, and placed for a period of time. The irradiated styrene-butadiene rubber emulsion and the above-mentioned white...

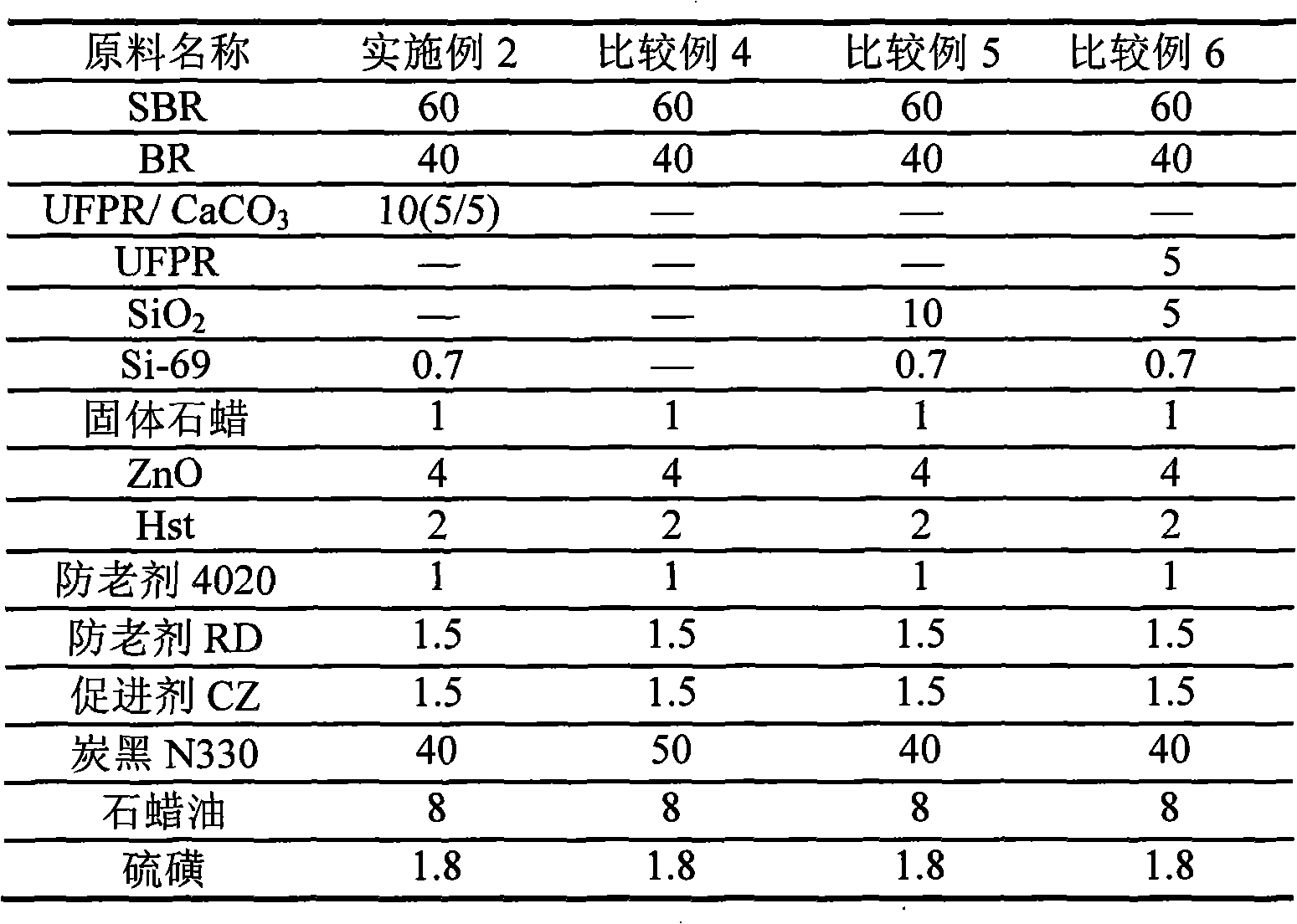

Embodiment 2

[0050] Compound powder preparation:

[0051] The irradiated styrene-butadiene rubber emulsion is the same as in Example 1. Calcium carbonate (CaCO3, Beijing University of Chemical Technology, with an average particle size of 40 nm) was mixed with water at a concentration of 5% by weight, dispersed by a high shear disperser, and left for a period of time. The irradiated styrene-butadiene rubber emulsion and the above-mentioned calcium carbonate slurries are matched in a ratio of 50:50 of their respective dry weights, stirred for one hour, then the mixed solution is spray-dried by a spray dryer, and the inlet temperature of the spray dryer is 140~160 ℃, The outlet temperature is 40-60°C, and the dried styrene-butadiene rubber / calcium carbonate composite powder (UFPR / CaCO3) is collected in a cyclone separator. 3 ).

[0052] Preparation of tire tread rubber compound:

[0053] The UFPR / CaCO prepared above was 3 After mixing with styrene-butadiene rubber (same as Example 1) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com