Dynamic vulcanization HPVC/EPDM thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, dynamic vulcanization technology, applied in the field of thermoplastic elastomer and its preparation, can solve problems such as poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

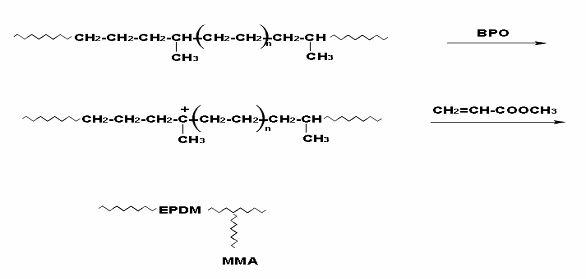

[0038] Add EPDM to a four-neck flask equipped with stirring, add solvent, control the temperature with a water bath, protect with N2, slowly add the MMA solution dissolved in BPO dropwise, react until the predetermined time, pour the reaction solution into methanol to precipitate, and remove unreacted The monomer and solvent were filtered by suction to obtain a crude product, which was extracted with isopropanol for 48 hours in a Soxhlet extractor to remove the PMMA homopolymer, and vacuum-dried to constant weight to obtain EPDM-g-MMA.

[0039] The experimental temperature is 80°C, the reaction time is 7h, the initiator is BPO, the amount of initiator is 0.10-0.15 parts, and the amount of monomer MMA is 12 parts, the grafting rate reaches 9.91%, and the grafting efficiency is 21.65%.

Embodiment 2

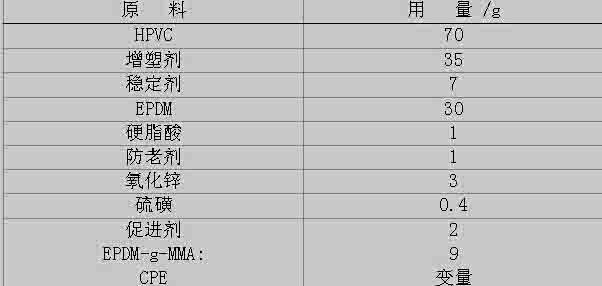

[0041] Experimental basic formula:

[0042]

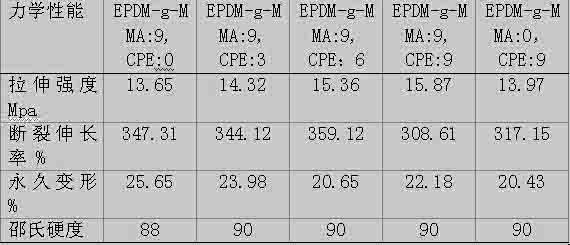

[0043] The influence of CPE and EPDM-g-MMA two compatibilizers used together on system performance:

[0044]

[0045] By using EPDM-g-MMA in combination with CPE, the mechanical properties of the system are significantly improved compared with only adding EPDM-g-MMA or CPE alone, the tensile strength reaches 15.87Mpa, and the elongation at break reaches 359.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com