Annealing treatment method for Al-0.5Cu conducting layer

A technology of annealing treatment and conductive layer, which is applied in the field of annealing treatment of conductive materials, can solve the problems of metal short circuit, affecting yield, short circuit, etc., and achieve the effect of avoiding growth and protrusion and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

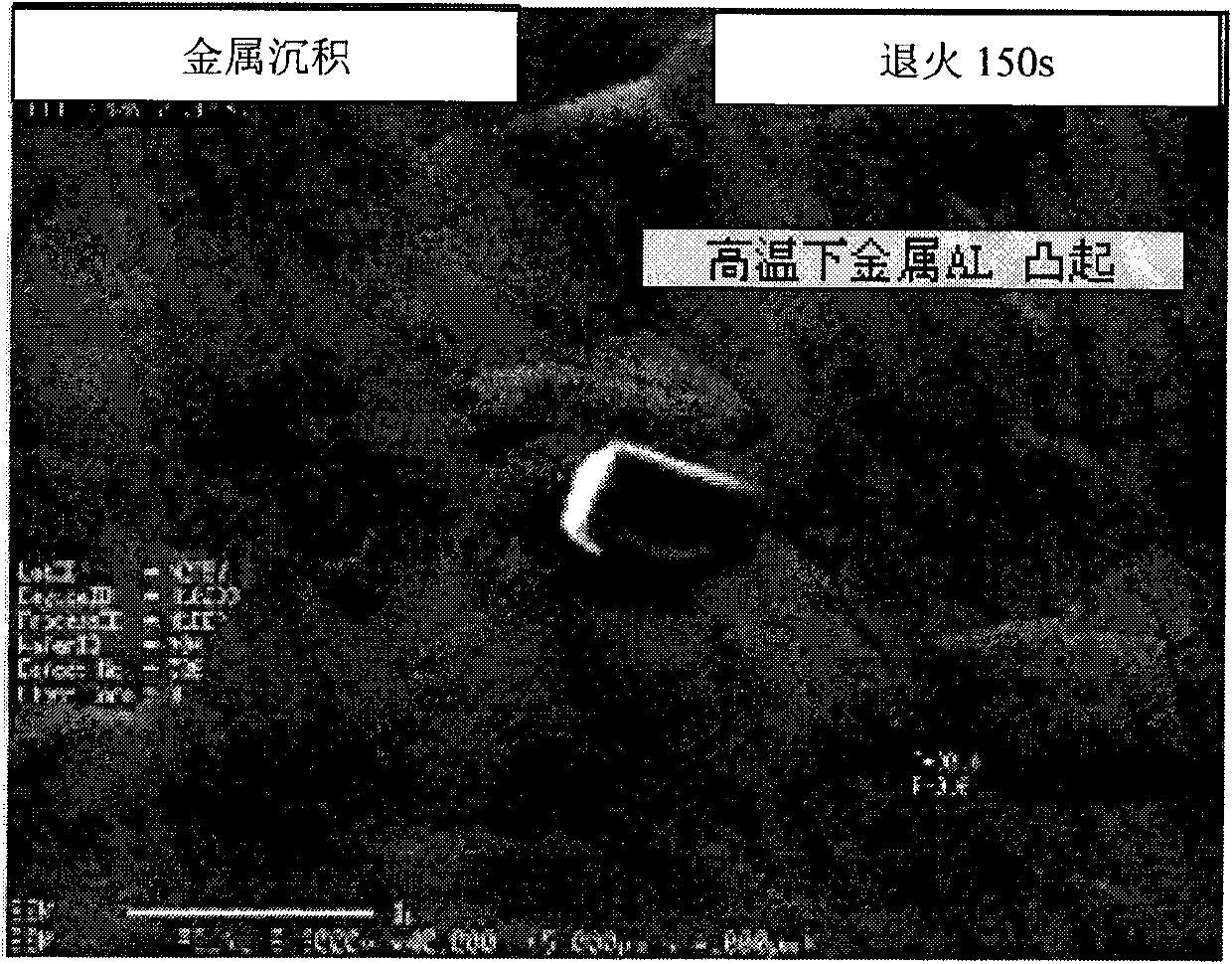

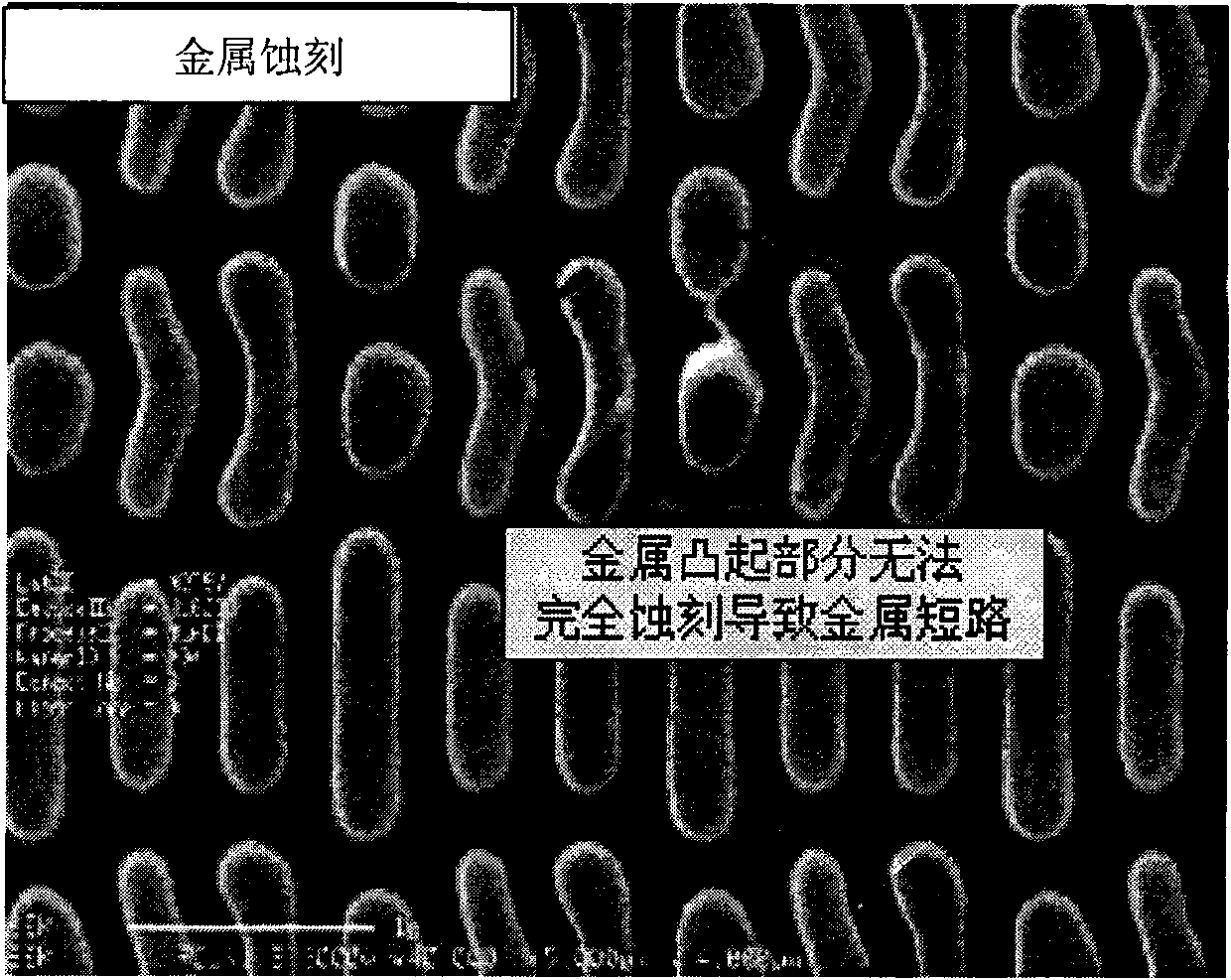

[0024] Set the thickness to The Al-0.5Cu conductive layer wafer was placed in a high-vacuum annealing furnace at a temperature of 420°C for 150s, and then cooled to room temperature at 7°C / s for subsequent etching. Figure 1A It is the SEM picture of the conductive layer obtained after 150s annealing treatment. It can be seen from the figure that there are obvious protrusions on the surface of the Al-0.5Cu conductive layer after annealing, and the outer periphery of the protrusions has very clear edges and corners, indicating that the Al particles have The tendency to aggregate grows. During the etching process, since the protrusion is difficult to etch completely, such as Figure 1B As shown in Fig. 1, there are irregular substances between the metals after etching, which eventually lead to short circuits.

Embodiment 2

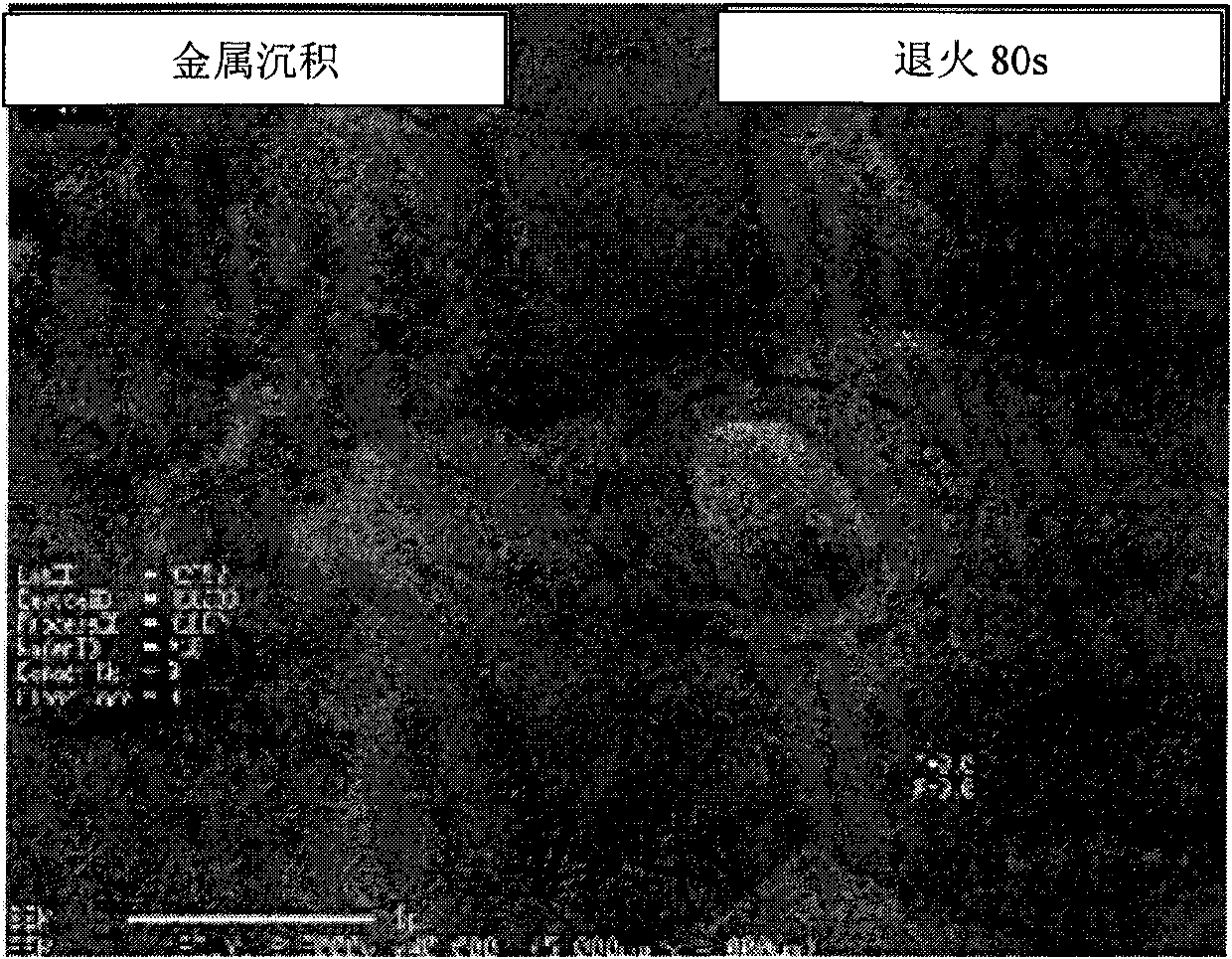

[0026] Set the thickness to The Al-0.5Cu conductive layer wafer was placed in a high-vacuum annealing furnace at a temperature of 420°C for 80s, and then cooled to room temperature at 7°C / s for the subsequent etching process. Compared with Example 1, this example shortens the holding time of the annealing treatment under other conditions being the same. Figure 2A It is the SEM image of the wafer obtained after the 80s annealing treatment, as can be seen from the figure, the Al-0.5Cu conductive layer surface after the annealing is not very smooth, there is a small part of protrusions, but compared with embodiment 1, its periphery is smoother . It shows that under this condition, most of the copper melts back into the alloy material, no obvious copper-rich region is formed, and no obvious Al particle protrusion occurs. So, after performing the post-etch process, such as Figure 2B As shown in the SEM image, the morphology is good, and there is no short circuit phenomenon ca...

Embodiment 3

[0029] Set the thickness to The Al-0.5Cu conductive layer wafer was placed in a high-vacuum annealing furnace at a temperature of 380°C for 150s, and then cooled to room temperature at 12°C / s for subsequent etching. Figure 3A It is the SEM image of the conductive layer obtained after the 150s annealing treatment. As can be seen from the figure, the surface of the Al-0.5Cu conductive layer after annealing has obvious protrusions, similar to Example 1, and the outer peripheral edges and corners of the protrusions are also relatively clear. It shows that Al particles tend to aggregate and grow. During the etching process, since the protrusion is difficult to etch completely, such as Figure 3B As shown in Fig. 1, there are irregular substances between the metals after etching, which eventually lead to short circuits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com