48MnV nitrogenous steel and nitrogen adding process thereof

A 48mnv, nitrogen steel technology, applied in the field of metallurgy, can solve the problems of waste of nitrogen-containing alloys, influence of users, and difficulty in achieving point composition control targets, and achieve the effect of improving strength and toughness, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is a 48MnV nitrogen-containing steel, which includes the following components by weight percentage: C: 0.45%, Si: 0.17%, Mn: 1.00%, V: 0.06%, Cr: 0.05%, Mo: 0.016%, Ni: 0.01%, Cu: 0.02%, N: 0.080%, P: 0.005%, S: 0.015%, O: 0.010%, Ceq: 0.087%, and the balance is Fe and unavoidable inclusions.

[0027] The nitrogen addition process of 48MnV nitrogen-containing steel is carried out according to the following steps: acceptance of raw and auxiliary materials→batching→electric furnace smelting→LF refining→VD degassing→feeding nitrided alloy wire→calcium treatment→static stirring→continuous casting→slab cooling inspection → Billet acceptance → heating → descaling → rolling → stack cooling → straightening → pickling → grinding → chamfering → internal and external flaw detection → finished product inspection → packing mark → weighing → storage;

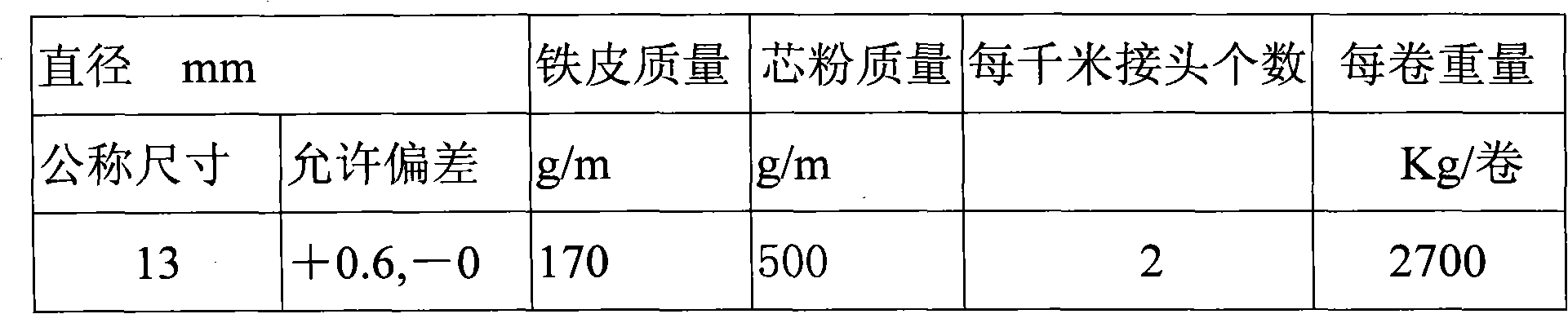

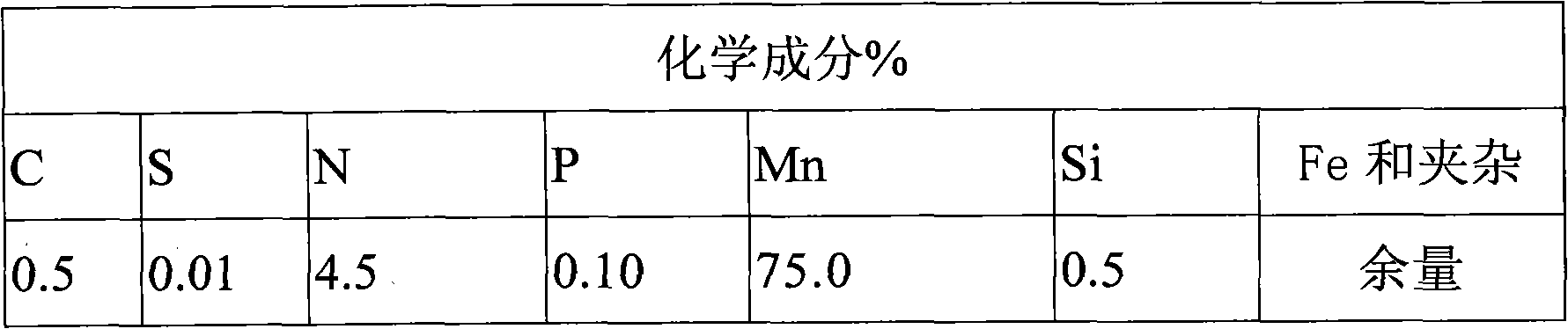

[0028] In the process of feeding nitrided alloy wires, the control target value is 0.0110%, and 239m manganese nitrid...

Embodiment 2

[0043] This embodiment is a 48MnV nitrogen-containing steel, which includes the following components by weight percentage: C: 0.49%, Si: 0.25%, Mn: 1.10%, V: 0.09%, Ti: 0.015%, Cr: 0.15%, Mo: 0.04%, Ni: 0.04%, Cu: 0.10%, N: 0.010%, P: 0.025%, S: 0.020%, O: 0.010%, Ceq: 0.091%, and the balance is Fe and unavoidable inclusions.

[0044] The nitrogen addition process of 48MnV nitrogen-containing steel is carried out according to the following steps: acceptance of raw and auxiliary materials→batching→electric furnace smelting→LF refining→VD degassing→feeding nitrided alloy wire→calcium treatment→static stirring→continuous casting→slab cooling inspection → Billet acceptance → heating → descaling → rolling → stack cooling → straightening → pickling → grinding → chamfering → internal and external flaw detection → finished product inspection → packing mark → weighing → storage;

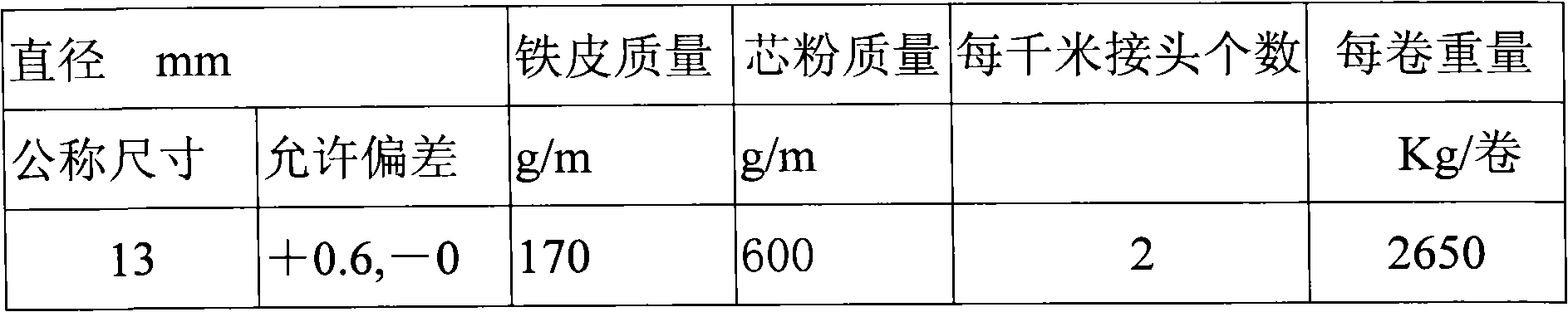

[0045] In the process of feeding nitrided alloy wires, the control target value is 0.0110%, and 239m manga...

Embodiment 3

[0060] This example is a 48MnV nitrogen-containing steel, which includes the following components by weight percentage: C: 0.51%, Si: 0.37%, Mn: 1.20%, V: 0.11%, Ti: 0.025, Cr: 0.25%, Mo: 0.06 %, Ni: 0.06%, Cu: 0.20%, N: 0.0150%, P: 0.035%, S: 0.035%, O: 0.020%, Ceq: 0.097%, and the balance is Fe and unavoidable inclusions.

[0061] The nitrogen addition process of 48MnV nitrogen-containing steel is carried out according to the following steps: acceptance of raw and auxiliary materials→batching→electric furnace smelting→LF refining→VD degassing→feeding nitrided alloy wire→calcium treatment→static stirring→continuous casting→slab cooling inspection → Billet acceptance → heating → descaling → rolling → stack cooling → straightening → pickling → grinding → chamfering → internal and external flaw detection → finished product inspection → packing mark → weighing → storage;

[0062] In the process of feeding nitrided alloy wires, the control target value is 0.0110%, and 239m mangane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com