Degradable environment-friendly dirt remover

A stripping agent, an environment-friendly technology, applied in the field of degradable and environment-friendly dirt stripping agents, can solve the problems of single function, non-environmental friendliness, narrow application range, etc., and achieve the effect of safe transportation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Prepare 100 kg of degradable and environment-friendly dirt stripping agent, and the raw materials used are all industrial products. Citric acid 70kg, sulfamic acid 18kg, sodium gluconate 6kg, polyaspartic acid sodium 3kg, thiourea 1.4kg and 2,2-dibromo-3-nitropropionamide 1.6kg. Put the above raw materials into a conical mixer and mix them evenly to get the finished product.

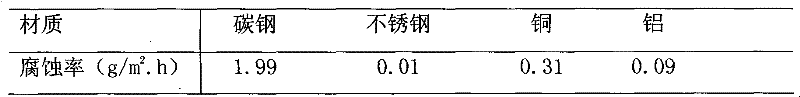

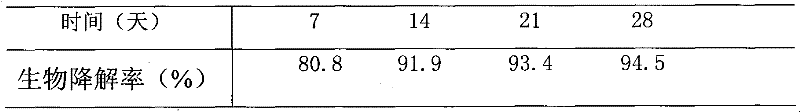

[0035] Corrosion test: Prepare the above-mentioned dirt stripping agent with deionized water to make a 5% aqueous solution of cleaning agent, place the above-mentioned 5% aqueous solution of cleaning agent in a 500ml Erlenmeyer flask, and hang test pieces of different materials in 5 % cleaning agent aqueous solution in the Erlenmeyer flask, and then place the Erlenmeyer flask in a constant temperature water bath at 50°C for a static test of 12 hours. Corrosion rate was measured with reference to the chemical industry standard HG / T2387-2007 "Quality Standards for Chemical Cleaning of...

Embodiment 2

[0042] Embodiment 2: Prepare 100 kg of degradable and environment-friendly dirt stripping agent, and the raw materials used are all industrial products. Citric acid 75kg, sulfamic acid 14kg, sodium gluconate 5kg, polyaspartic acid sodium 2.8kg, thiourea 1.6kg and 2,2-dibromo-3-nitropropionamide 1.6kg. Put the above raw materials into a conical mixer and mix them evenly to get the finished product.

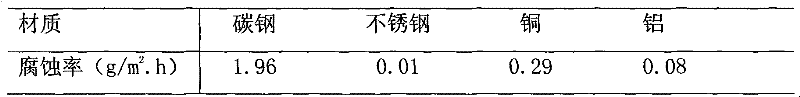

[0043] Corrosion test: Prepare the above-mentioned dirt stripping agent with deionized water to make a 5% aqueous solution of cleaning agent, place the above-mentioned 5% aqueous solution of cleaning agent in a 500ml Erlenmeyer flask, and hang test pieces of different materials in 5 % cleaning agent aqueous solution in the Erlenmeyer flask, and then place the Erlenmeyer flask in a constant temperature water bath at 50°C for a static test of 12 hours. Corrosion rate was measured with reference to the chemical industry standard HG / T2387-2007 "Quality Standards for Chemical Cleaning ...

Embodiment 3

[0050] Embodiment 3: Prepare 100 kg of degradable and environment-friendly dirt stripping agent, and the raw materials used are all industrial products. Citric acid 73kg, sulfamic acid 16kg, sodium gluconate 5kg, polyaspartic acid sodium 2.9kg, thiourea 1.5kg and 2,2-dibromo-3-nitropropionamide 1.6kg. Put the above raw materials into a conical mixer and mix them evenly to get the finished product.

[0051] Corrosion test: Prepare the above-mentioned dirt stripping agent with deionized water to make a 5% aqueous solution of cleaning agent, place the above-mentioned 5% aqueous solution of cleaning agent in a 500ml Erlenmeyer flask, and hang test pieces of different materials in 5 % cleaning agent aqueous solution in the Erlenmeyer flask, and then place the Erlenmeyer flask in a constant temperature water bath at 50°C for a static test of 12 hours. Corrosion rate was measured with reference to the chemical industry standard HG / T2387-2007 "Quality Standards for Chemical Cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com