Method for improving data processing of absorption loss measurement of optical elements

A technology for optical components and data processing, which is applied in the direction of optical instrument testing, measuring devices, testing optical performance, etc., and can solve problems such as large absorption loss measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

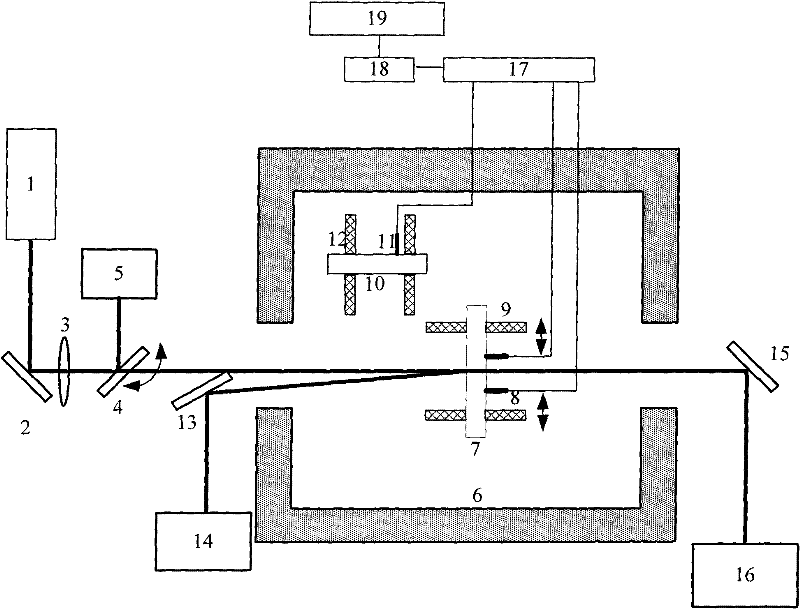

[0048] Attached below figure 1 The implementation process of the present invention is described in detail. Such as figure 1 As shown, the laser calorimetric absorption loss measurement of the present invention consists of heating the laser light source 1, the reflecting mirror 2, the focusing lens 3, the electric optical shutter 4, the power meter 5, the adiabatic sample chamber 6, the optical element under test 7, the optical element under test Temperature sensor 8, optical element holder under test 9, reference optical element 10, reference optical element temperature sensor 11, reference optical element holder 12, mirror 13, light absorber 14, reflector 15, light absorber 16, bridge magnification Circuit 17, A / D converter 18 and computer 19 are composed. The thick line represents the optical path, and the thin line represents the signal connection line.

[0049] The laser beam output by the heating laser light source 1 is refracted by the 45-degree reflector 2 and focused b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com