Unsteady-state sectional influent water depth nitrogen and phosphorus removal process control system and control method

A technology of process control system and segmented water intake, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of dissolved oxygen concentration disturbance in the aeration tank, large influence of human factors, time delay lag, etc., to achieve reduction Aeration energy consumption, avoiding incomplete effects, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment describe the present invention in detail:

[0031] Taking the effluent from the primary sedimentation tank of a sewage treatment plant in Beijing as the research object (COD=119-565mg / L, TN=24.6-79.5mg / L, TP=0.48-13.3mg / L, C / N=1.5-6.4, C / N=1.5-6.4, P=35.7-74.5), hydraulic retention time 8-10h, sludge age 8-12d, average sludge concentration 5000±150mg / L, sludge reflux ratio 0.5-0.75.

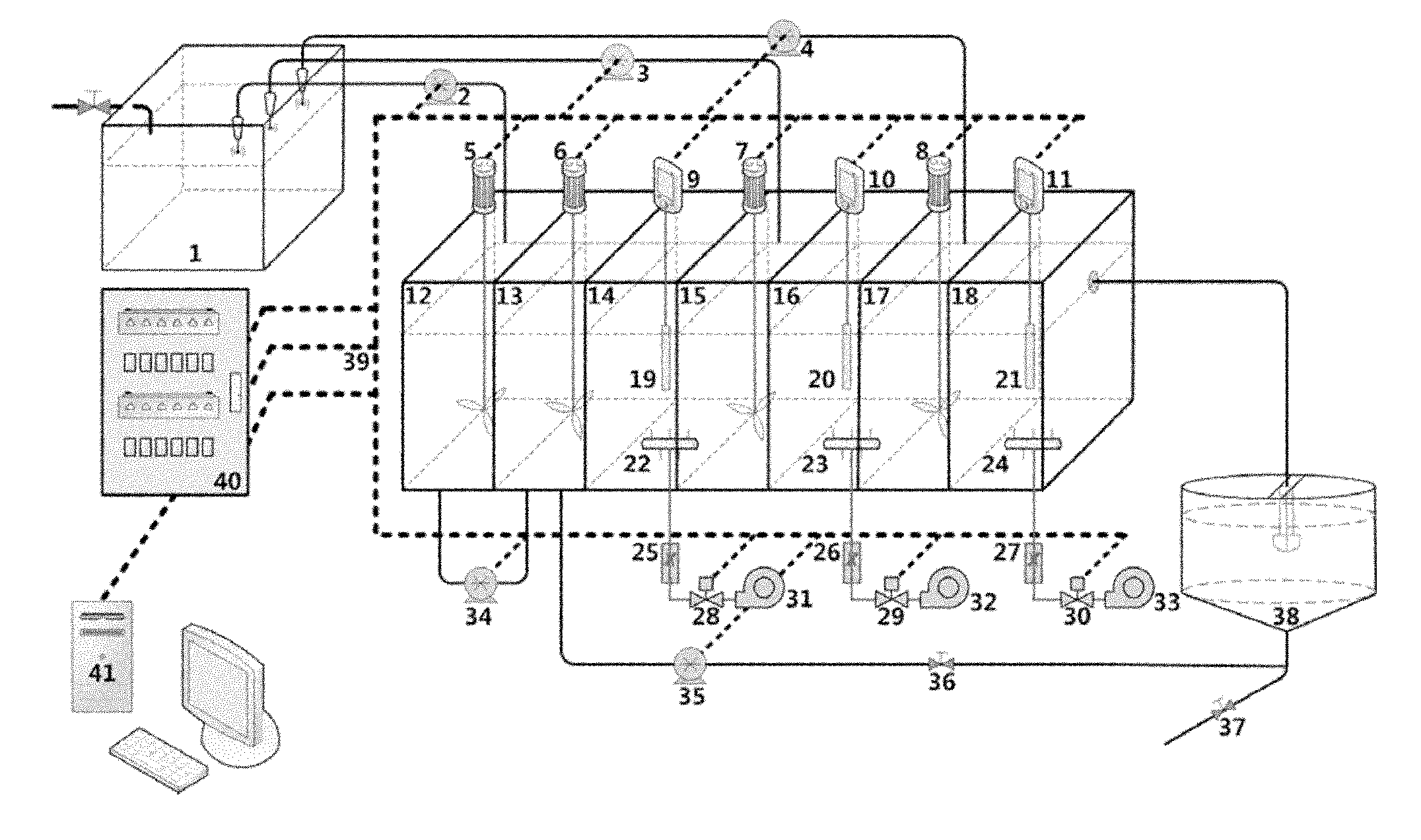

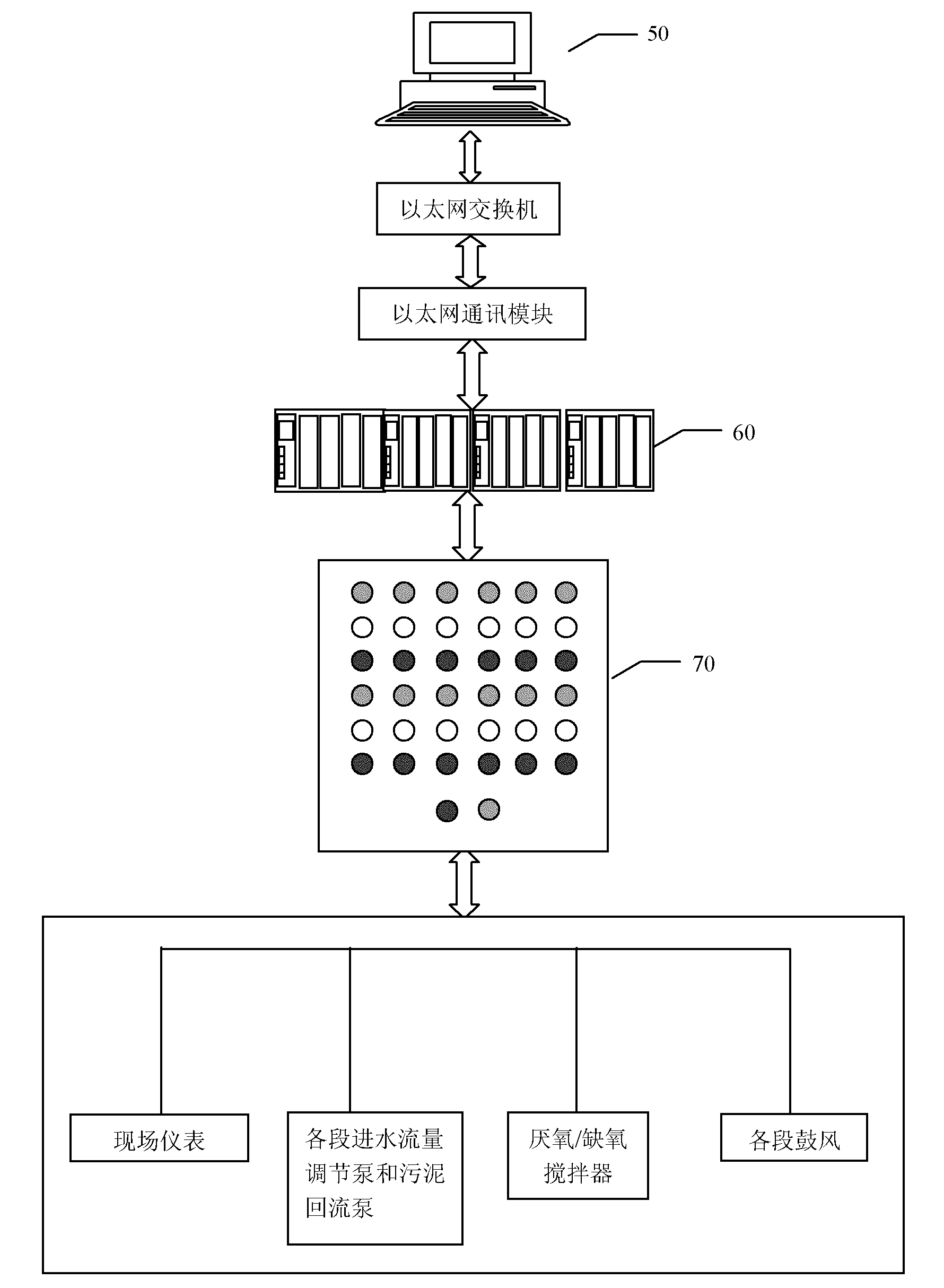

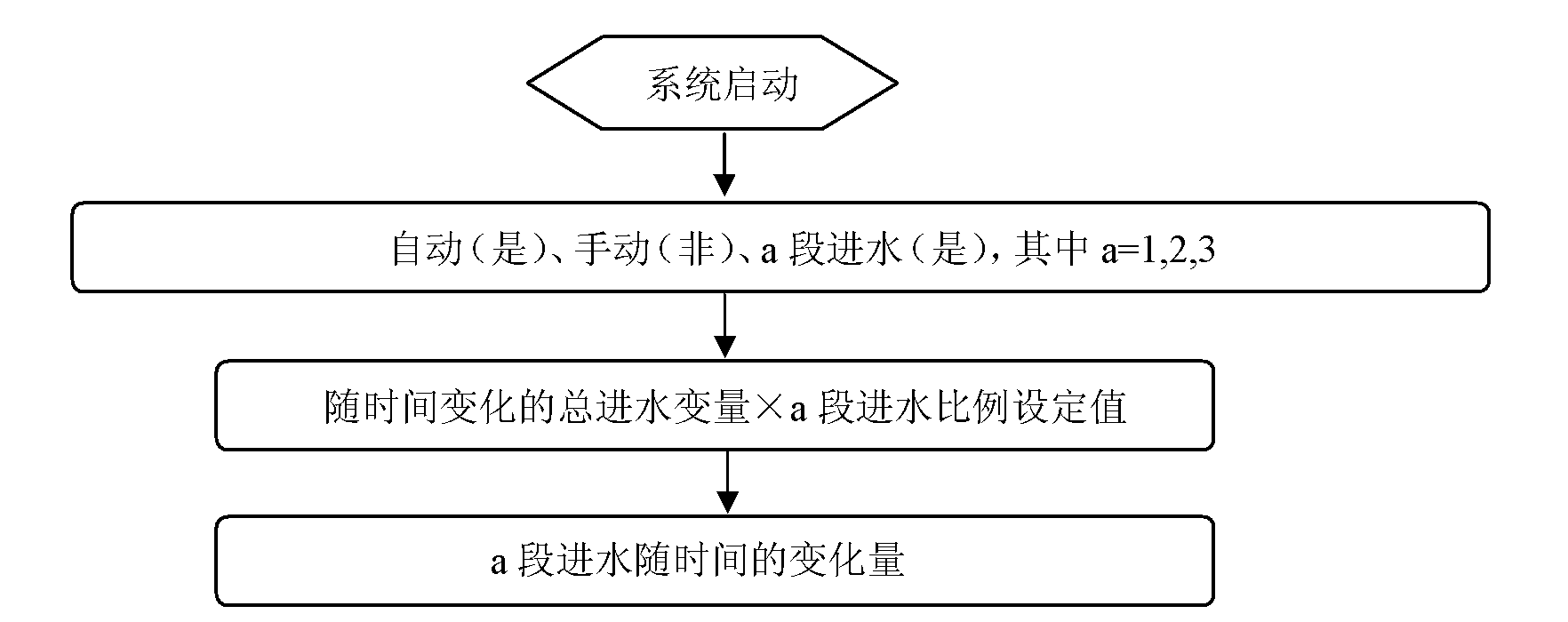

[0032] in such as figure 1 In the unsteady state condition shown, the process control system of the improved stepwise denitrification and dephosphorization process of water inflow, the first section of water inlet pump 2, the second section of water inlet pump 3, the third section of water inlet pump 4 and the control bus connected to the sewage tank 1 39 connection; anaerobic reactor 12, first section anoxic reactor 13, first section aerobic reactor 14, second section anoxic reactor 15, second section aerobic reactor 16, third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com