Magnetic field modulation type Halbach permanent magnetic direct drive motor

A technology of permanent magnet direct drive and magnetic field modulation, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, synchronous machine parts, etc., can solve the problem of reducing the magnetic flux of the outer rotor yoke Density, magnetic flux leakage and large magnetic density of the yoke, etc., to achieve the effect of light weight, reduced core loss, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below is the concrete implementation of the present invention, is used for further description:

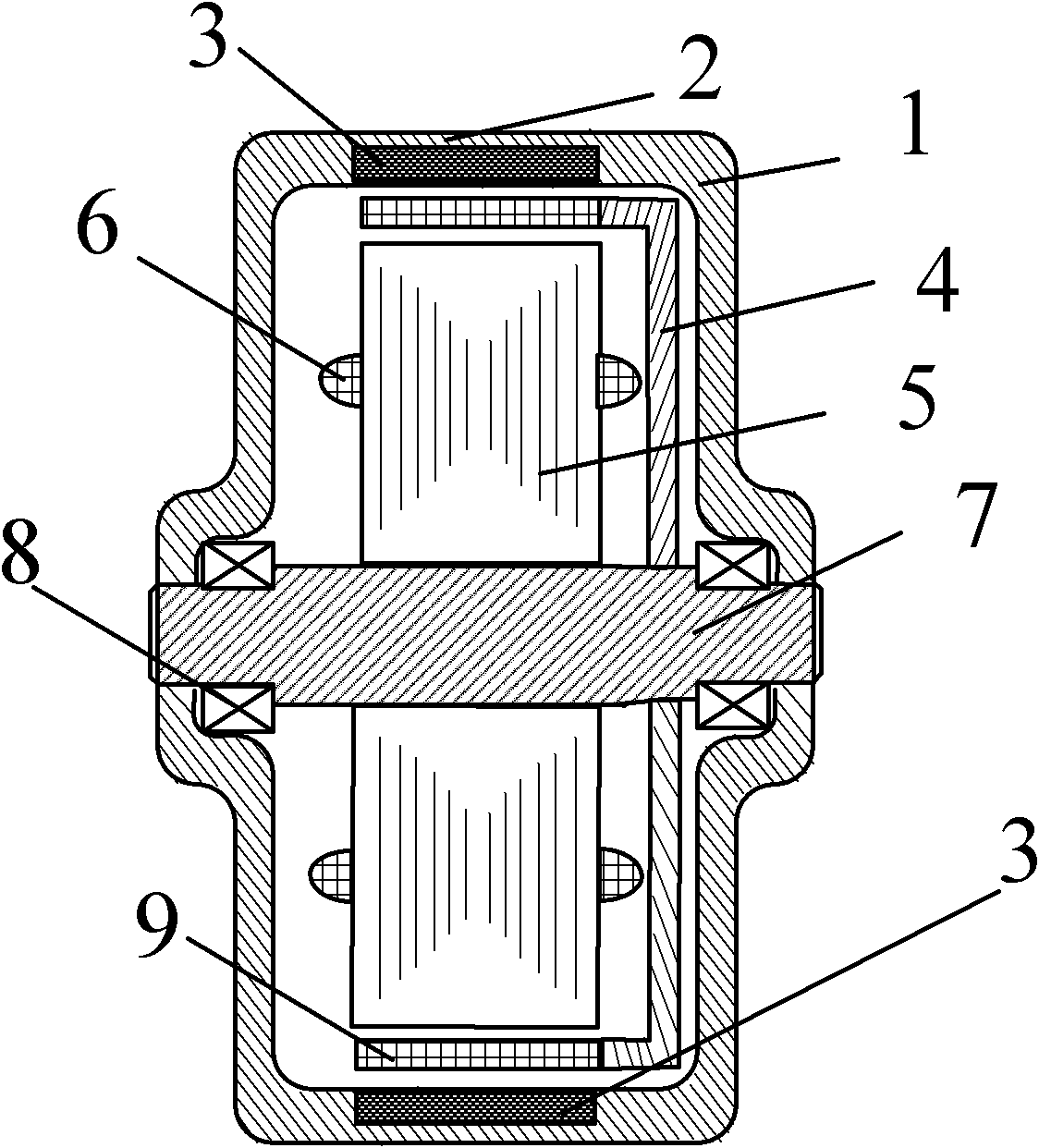

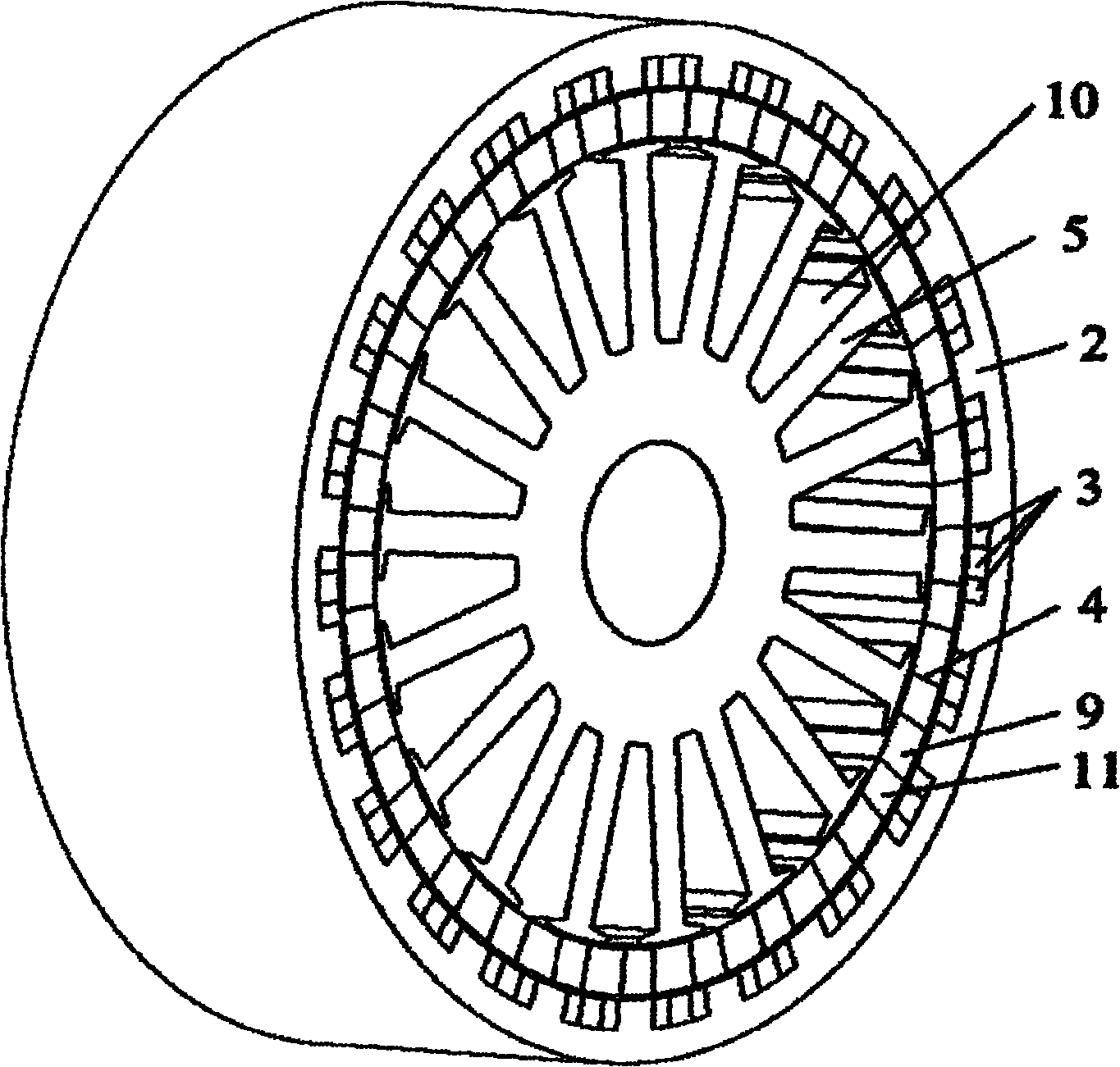

[0023] The present invention is a novel magnetic field modulation type Halbach permanent magnet direct drive motor device, which comprises an outer rotor (1), an outer rotor yoke (2), a permanent magnet (3), a magnetic adjustment ring (4), and a stator (5) , armature winding (6), motor shaft (7), bearing (8); the outer rotor (1) of the motor is rotationally connected with the motor shaft (7) through the bearing (8), and the permanent magnet (3) is evenly embedded along the circumferential direction Place on the outer rotor yoke (2). The stator (5) adopts the stator structure of the traditional outer rotor permanent magnet brushless DC motor, and the magnetic conducting blocks (9) of the magnetic adjusting ring are evenly distributed along the circumferential direction. The motor shaft (7) is used to fix the motor stator (5) and the static magnetic adjustment ring (4), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com