Porous film for separator, battery separator, battery electrode, and manufacturing methods therefor, and lithium secondary battery

The technology of a porous membrane and a manufacturing method is applied in the field of porous membranes for separators, separators for batteries, electrodes for batteries, and the manufacture of these and secondary lithium batteries, which can solve problems such as short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0025] First, the porous membrane for a separator and its manufacturing method, the battery separator and its manufacturing method, the battery electrode and its manufacturing method of this invention are demonstrated.

[0026] The porous membrane forming the battery separator of the present invention (hereinafter simply referred to as "separator") is a porous membrane formed by containing inorganic oxide particles and binding the above-mentioned inorganic oxide particles with a binder. As the above-mentioned inorganic oxide particles, the alkali metal element contained in the above-mentioned porous film, especially Na, is a film having a concentration of 1000 ppm or less (mass basis, the same below).

[0027] Even among the alkali metal elements contained in the separator, the alkali metal elements that exist in a water-elutable state, especially Na, cause the characteristics of the secondary lithium battery to deteriorate during long-term repeated charging and discharging or ...

Embodiment approach 2

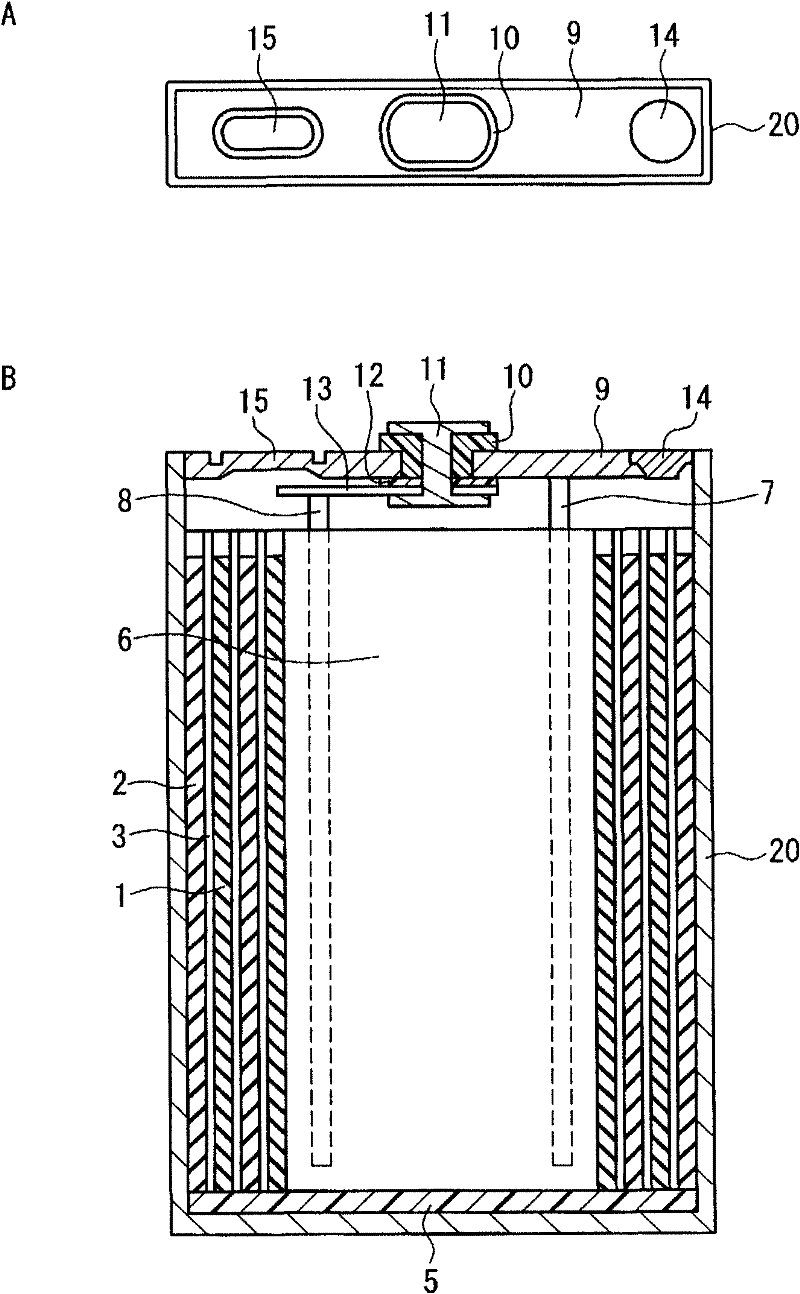

[0103] Next, the secondary lithium battery of the present invention will be described.

[0104] As long as the secondary lithium battery of the present invention uses the battery separator of the present invention, other configurations and structures are not particularly limited, and configurations and structures used in conventional secondary lithium batteries can be applied.

[0105] Examples of the form of the secondary lithium battery include a cylindrical shape (square or cylindrical) in which a steel can, an aluminum can, or the like is used as an exterior can. In addition, it may be a soft-package battery in which a metal-deposited laminated film is used as an exterior body.

[0106] The positive electrode is not particularly limited as long as it is a positive electrode used in conventional secondary lithium batteries, that is, a positive electrode containing an active material capable of absorbing and releasing Li ions. For example, as the positive electrode active m...

Embodiment 1

[0126] Diaphragm production

[0127] Plate-shaped boehmite (aspect ratio: 10) was repeatedly washed with water and dried at 120° C. as inorganic oxide particles. Put 0.5g of dried platy boehmite on 25cm 3 The ion-exchanged water was soaked at 25°C for 12 hours, the soaked ion-exchanged water was diluted 10 times, and the amount of alkali metal elements dissolved in the ion-exchanged water was measured by ICP spectroscopic analysis. As a result, the alkali metal element basically consisted of only Na, and the amount thereof was determined to be 500 ppm based on the weight of platy boehmite.

[0128] To 500 g of the platy boehmite washed with water, 500 g of ion-exchanged water and 5 g of a 40% by mass ammonium polycarboxylate dispersant were added, and dispersion treatment was performed with a ball mill to prepare a dispersion. The particle size of the platy boehmite in the dispersion liquid was measured with a laser scattering particle size distribution meter, and the averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com