1,3-propanediol catalyst prepared by directly hydrotreating glycerol and preparation method thereof

A catalyst, propylene glycol technology, applied in molecular sieve catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low selectivity, low economy, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

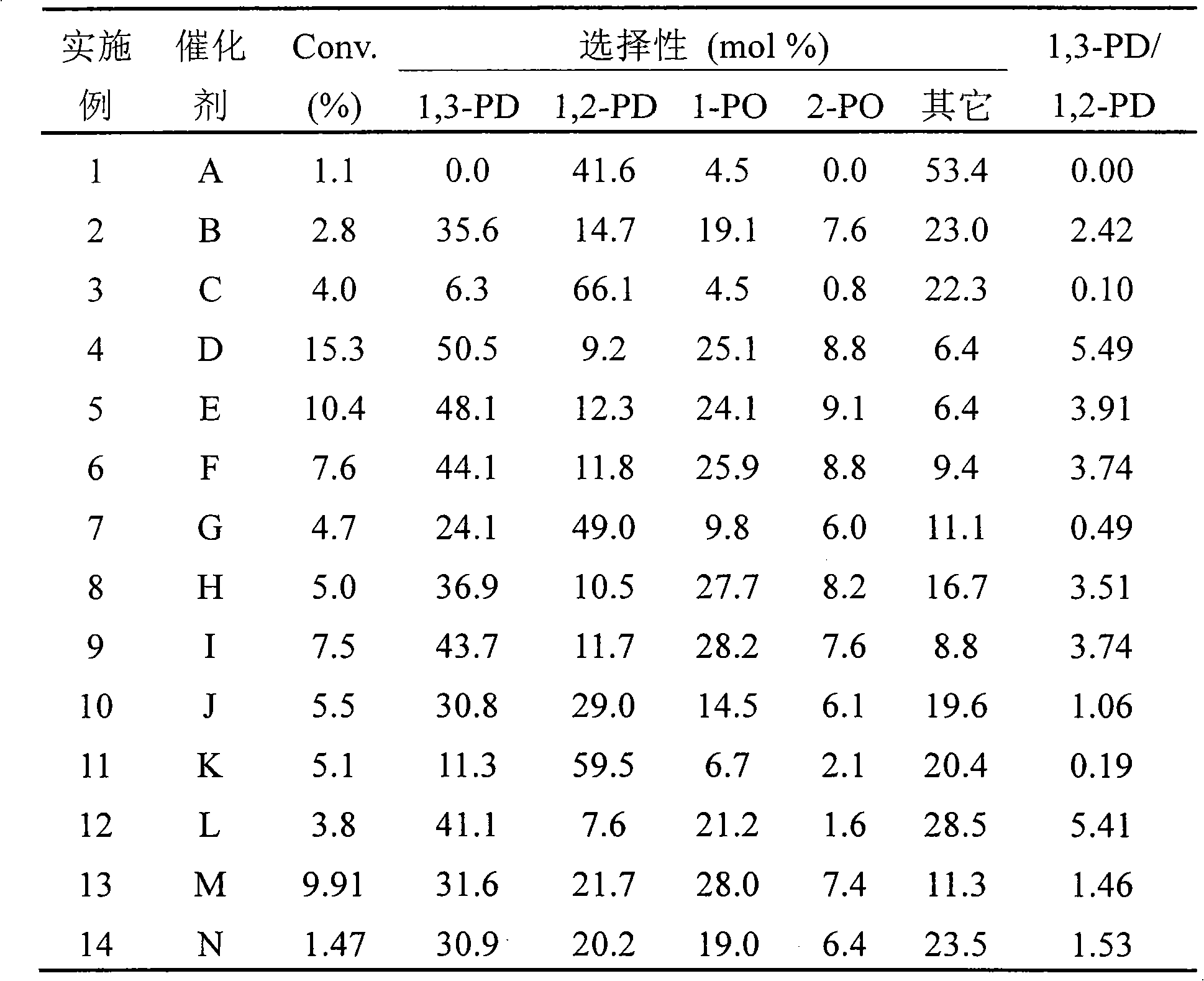

Examples

Embodiment 1

[0027] The catalyst used is Pt / SiO 2 , denoted as catalyst A. The weight composition of catalyst A is: Pt%=2%, the rest is carrier SiO 2 . The preparation steps of catalyst A are:

[0028] Impregnate the support SiO with an aqueous solution of chloroplatinic acid containing the desired amount of Pt 2 , dried at 120°C for 3h, and calcined at 500°C for 3h to obtain catalyst A.

Embodiment 2

[0030] The catalyst used is Pt / WO 3 / SiO 2 , denoted as catalyst B. Catalyst B weight composition is: Pt%=2%, WO 3 %=5%, the rest is carrier SiO 2 . The preparation step of catalyst B comprises:

[0031] a) Impregnate the carrier SiO with an aqueous solution of ammonium metatungstate containing the desired amount of W 2 , dried at 120°C for 3h, and calcined at 600°C for 6h to obtain WO 3 / SiO 2 .

[0032] b) impregnating the WO obtained in step a with an aqueous solution of chloroplatinic acid containing the desired amount of Pt 3 / SiO 2 , dried at 120°C for 3h, and calcined at 500°C for 3h to obtain catalyst B.

Embodiment 3

[0034] The catalyst used is Pt / TiO 2 / SiO 2 , denoted as catalyst C. Catalyst C weight composition is: Pt%=2%, TiO 2 %=10%, the rest is carrier SiO 2 . The preparation steps of catalyst C comprise:

[0035] a) Impregnation of the carrier SiO with an ethanol solution of tetrabutyl titanate containing the desired amount of Ti 2 , dried at 120°C for 3h, and calcined at 600°C for 6h to obtain TiO 2 / SiO 2 .

[0036] b) Impregnate the TiO obtained in step a) with an aqueous solution of chloroplatinic acid containing the desired amount of Pt 2 / SiO 2 , dried at 120°C for 3h, and calcined at 500°C for 3h to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com