Preparation method of water-soluble 2'-hydroxylpropylchitosan

A technology of dihydroxypropyl shell and chitosan, which is applied in the field of water-soluble biomaterials, can solve the problems affecting the application range of chitosan, and achieve the effect of strong hydrophilicity and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

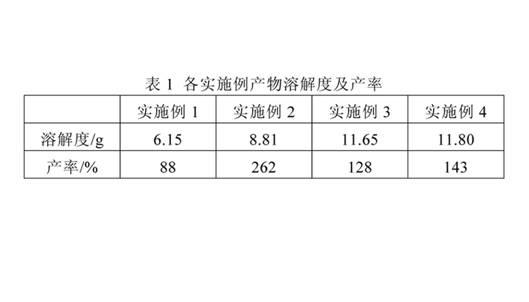

[0017] Add 2g of chitosan to 5mL of 30~40wt% NaOH and soak evenly for 2 hours, then freeze-dry; mix the dried alkaline chitosan with 20mL of isopropanol and stir for 30min, add 15mL of self-made glycidol (glycidol preparation method see: Yu Liangmin, Han Qinglong, Li Changcheng, et al. Low-temperature synthesis and characterization of glycidol [J]. Fine Chemical Industry, 2007, 24(5): 517-520.), heated to 45°C for 8 hours (chitosan, isopropyl molar ratio of alcohol to glycidol = 1:22.4:19); after the reaction, add 25mL of distilled water (molar ratio of chitosan to water = 1:119) and stir until completely dissolved, centrifuge at 4000r / min for 10min, and take the supernatant The isopropanol was removed by rotary evaporation at 80°C; after cooling, the pH value was adjusted to neutral with dilute hydrochloric acid, and the dialysis bag was dialyzed for 24 hours and then freeze-dried. The color of the product is light yellow, and its solubility and yield are shown in Table 1.

Embodiment 2

[0019] Add 2g of chitosan to 5mL of 30~40wt% NaOH and soak evenly for 3 hours, then freeze-dry; mix the dried alkaline chitosan with 20mL of isopropanol and stir for 30min, add 20mL of self-made glycidol, heat up to 60℃ for 8h (The molar ratio of chitosan, isopropanol and glycidol=1:22.4:25); after the reaction, add 25mL of distilled water (the molar ratio of chitosan and water=1:119) and stir until completely dissolved, 4000r / min After centrifugation for 10 min, the supernatant was rotatably evaporated at 80°C to remove isopropanol; after cooling, the pH value was adjusted to neutral with dilute hydrochloric acid, and the dialysis bag was dialyzed for 24 h and then freeze-dried. Product color is white, and its solubility and productive rate are as shown in Table 1.

Embodiment 3

[0021] Add 2g of chitosan to 5mL of 30~40wt% NaOH and soak evenly for 1.5 hours, then freeze-dry; mix the dried alkaline chitosan with 20mL of isopropanol and stir for 30min, add 15mL of self-made glycidol, heat up to 60℃ for 8h (The molar ratio of chitosan, isopropanol and glycidol=1:22.4:19); after the reaction, add 25mL of distilled water (the molar ratio of chitosan and water=1:119) and stir until completely dissolved, 4000r / min After centrifugation for 10 min, the supernatant was rotatably evaporated at 80°C to remove isopropanol; after cooling, the pH value was adjusted to neutral with dilute hydrochloric acid, and the dialysis bag was dialyzed for 24 h and then freeze-dried. Product color is white, and its solubility and productive rate are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com