Method for extracting scandium from modified red mud by using composite extractant

A composite extractant and red mud technology, applied in the field of scandium extraction, can solve the problems of no industrial production, large acid consumption, low recovery rate, etc., and achieve the effects of high recovery rate, reduced acid consumption and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

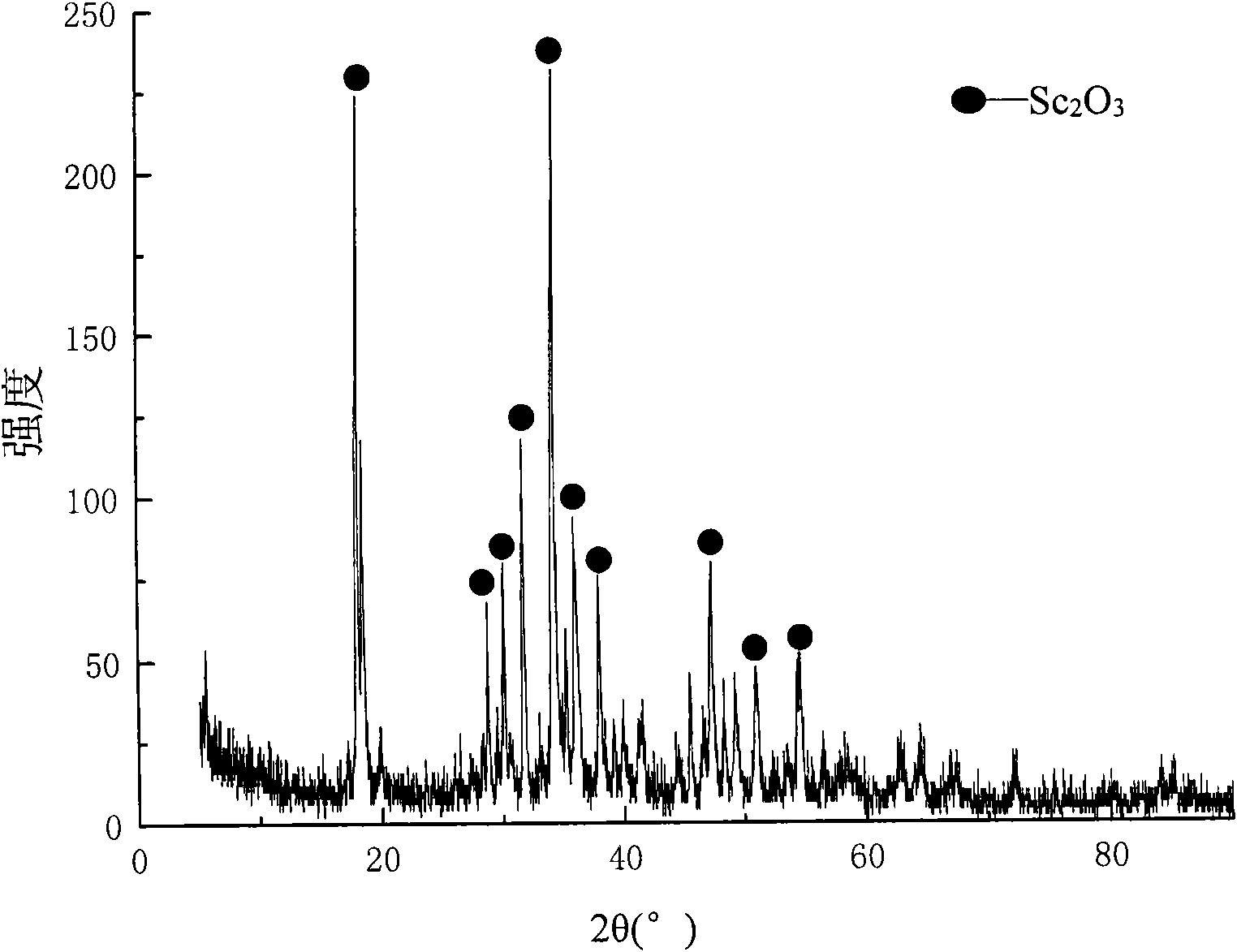

Image

Examples

Embodiment 1

[0023] A method for extracting scandium from modified red mud with a composite extractant is carried out in the following steps:

[0024] In the first step, the preparation of modified red mud, the following raw materials are configured in parts by weight:

[0025] First, take red mud, Na 2 CO 3 powder, CaO powder and water, red mud: Na 2 CO 3 : CaO: water = 10: 3: 2: 20; red mud, Na 2 CO 3 Put the powder, CaO powder and water into the crucible and stir evenly; then put the mixed liquid into the crucible boiler and roast it at 1080°C for 45min; then cool it to room temperature naturally; then, use 1mol / L of The NaOH solution was dissolved at 80°C, the weight ratio of the calcined product to the NaOH solution was 1:5, and the dissolution time was 30 minutes. The obtained dissolved product was washed twice with water, and then filtered and dried to obtain modified red mud;

[0026] In the second step, the modified red mud obtained in the first step is leached with 6.5mol / L...

Embodiment 2

[0036] A method for extracting scandium from modified red mud with a composite extractant is carried out in the following steps:

[0037] In the first step, the preparation of modified red mud, the following raw materials are configured in parts by weight:

[0038] First, take red mud, Na 2 CO 3 powder, CaO powder and water, red mud: Na 2 CO 3 : CaO: water = 10: 3: 2: 30; red mud, Na 2 CO 3 Put powder, CaO powder and water into the crucible, stir evenly; then put the mixed liquid into the crucible boiler and roast at 1050°C for 30min; The NaOH solution was dissolved at 75°C, the weight ratio of the calcined product to the NaOH solution was 1:4, and the dissolution time was 20 minutes. The obtained dissolved product was washed three times with water, and then filtered and dried to obtain modified red mud;

[0039] In the second step, the modified red mud obtained in the first step is leached with 6.5mol / L hydrochloric acid, the weight ratio of the modified red mud to hydr...

Embodiment 3

[0048] A method for extracting scandium from modified red mud with a composite extractant is carried out in the following steps:

[0049] In the first step, the preparation of modified red mud, the following raw materials are configured in parts by weight:

[0050] First, take red mud, Na 2 CO 3 powder, CaO powder and water, red mud: Na 2 CO 3 : CaO: water = 10: 4: 3: 50; red mud, Na 2 CO 3 Put the powder, CaO powder and water into the crucible and stir evenly; then put the mixed liquid into the crucible boiler and roast at 1100°C for 60min; The NaOH solution was dissolved at 90°C, the weight ratio of the calcined product to the NaOH solution was 1:6, and the dissolution time was 40 minutes. The obtained dissolved product was washed twice with water, and then filtered and dried to obtain modified red mud;

[0051] The second step to the seventh step are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com