Method for controlling flow of simulation fire source

A technology for simulating fire source and flow control, which is applied in combustion methods, combustion control, and fuel supply regulation. The effect of reducing the impact and facilitating the remote control operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

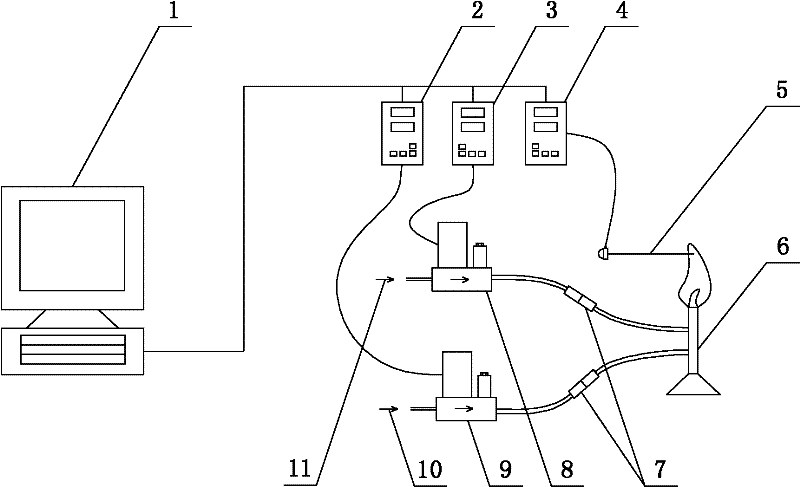

[0031] Such as figure 1 As shown, a flow control device simulating a fire source includes a computer 1, a gas intelligent control instrument 2, a gas-supporting intelligent control instrument 3, a temperature acquisition intelligent instrument 4, a thermocouple 5, a burner 6, a gas source 10, a gas Mass flowmeter 9, gas-supporting gas source 11, gas-supporting mass flowmeter 8, the gas gas source 10 is connected to the inlet of the gas mass flowmeter 9, and the outlet of the gas mass flowmeter 9 is connected to the burner 6 through the quick connector 7 , the gas-supporting gas source 11 is connected to the inlet of the gas-supporting mass flowmeter 8, and the outlet of the combustion-supporting gas mass flowmeter 8 is connected to the burner 6 through the quick joint 7; the gas mass flowmeter 9, the gas intelligent control instrument 2, the computer 1 are connected in sequence, the gas-supporting mass flowmeter 8, the gas-supporting intelligent control instrument 3, and the c...

Embodiment 2

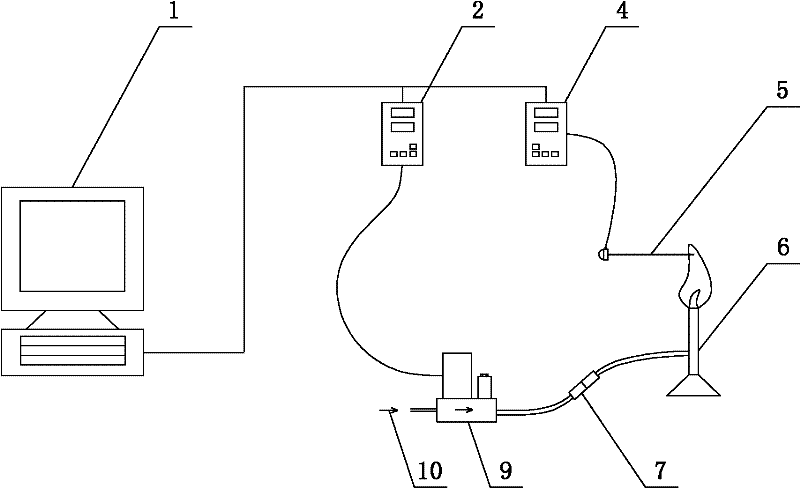

[0046] Present embodiment except following feature other structures are with embodiment 1: as image 3 As shown, the gas-supporting mass flowmeter 8, the gas-supporting intelligent control instrument 3, and the gas-supporting gas source 11 in the device of Example 1 are removed, and the combustion-supporting gas is not used when simulating the combustion of the fire source.

[0047] The gas intelligent control instrument 2 , the gas-supporting intelligent control instrument 3 , and the temperature acquisition intelligent instrument 4 communicate directly with the computer 1 through the USB interface.

[0048] The type of the gas source 10 is methane.

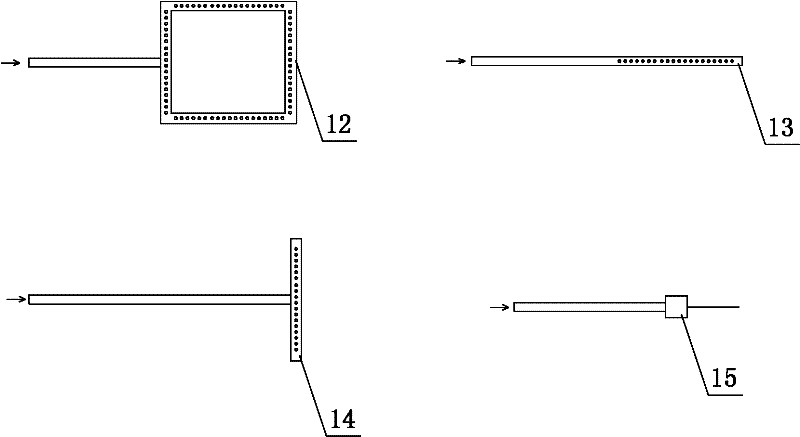

[0049] The burner is a needle flame burner with a structure such as figure 2 15 in.

Embodiment 3

[0051] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the input and output control signals of the gas mass flowmeter 9 and the assisted gas mass flowmeter 8 are voltage signals of 0-5V.

[0052] The gas source 10 is propane.

[0053] The type of the combustion-supporting gas source 11 is oxygen.

[0054] The burner is a linear burner with a structure such as figure 2 13 in.

[0055] In the step (3) of the flow control method for simulating fire sources, after the temperature acquisition intelligent instrument transmits the temperature data to the computer, the computer judges whether the temperature data is in the set temperature range, if the temperature data is higher than the set temperature range Temperature range, then the computer reduces the original set gas and assisted gas flow, and vice versa, the gas and assisted gas flow is reduced according to 0.05-0.2L / min, until the temperature data obtained by feedback...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com