Leakage detection method using compressed air as medium

A technology of leak detection and compressed air, which is applied in the field of leak detection and can solve problems such as low efficiency, low degree of automation, and long detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

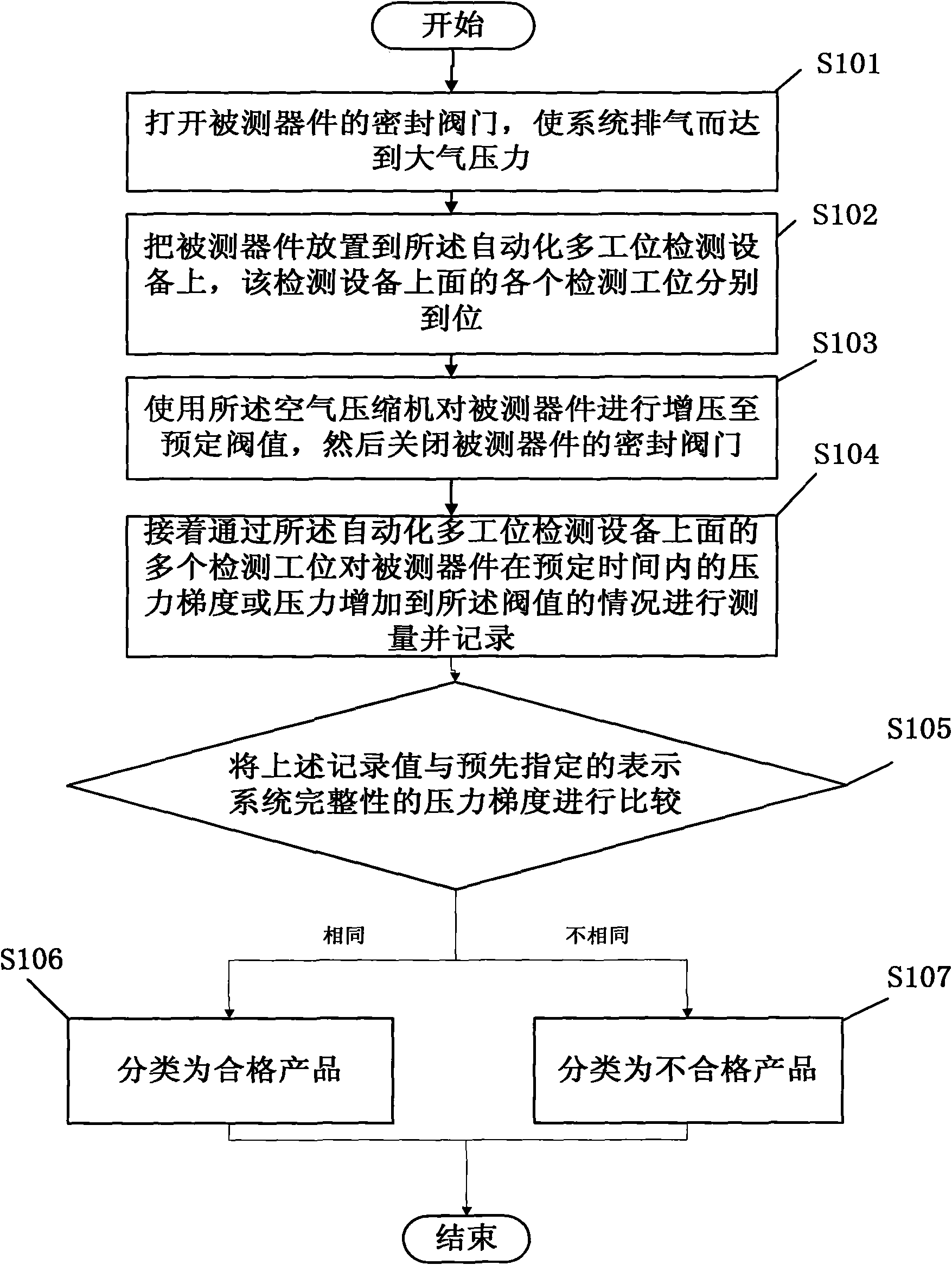

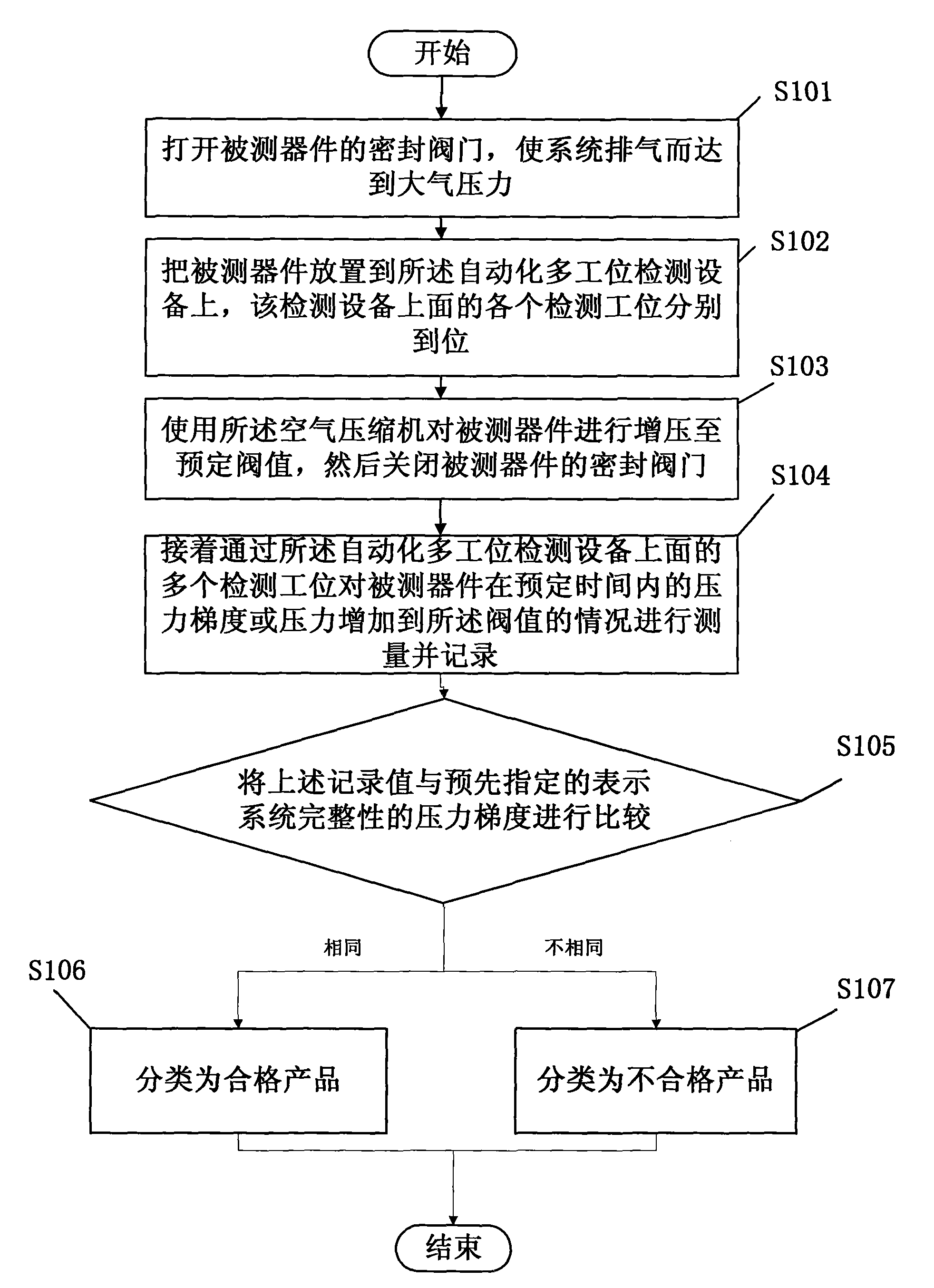

[0019] figure 1 It is a flowchart of a leak detection method using compressed air as a medium of the present invention, comprising the following steps:

[0020] In step 101, the sealing valve of the device under test is opened to exhaust the system to atmospheric pressure;

[0021] In step 102, the device under test is placed on the automatic multi-station detection equipment, and each detection station on the detection equipment is in place respectively;

[0022] In step 103, use the air compressor to pressurize the device under test to a predetermined threshold, and then close the sealing valve of the device under test;

[0023] In step 104, then measure and record the pressure gradient of the device under test or the pressure increase to the threshold value within a predetermined time through multiple detection stations on the automatic multi-station detection equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com