Method for optimally designing dynamic property of complete machine tool

A technology of optimized design and dynamic performance, applied in calculation, special data processing applications, instruments, etc., can solve problems such as poor accuracy and low calculation accuracy, and achieve the effect of ensuring accurate assembly and simplifying the spindle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

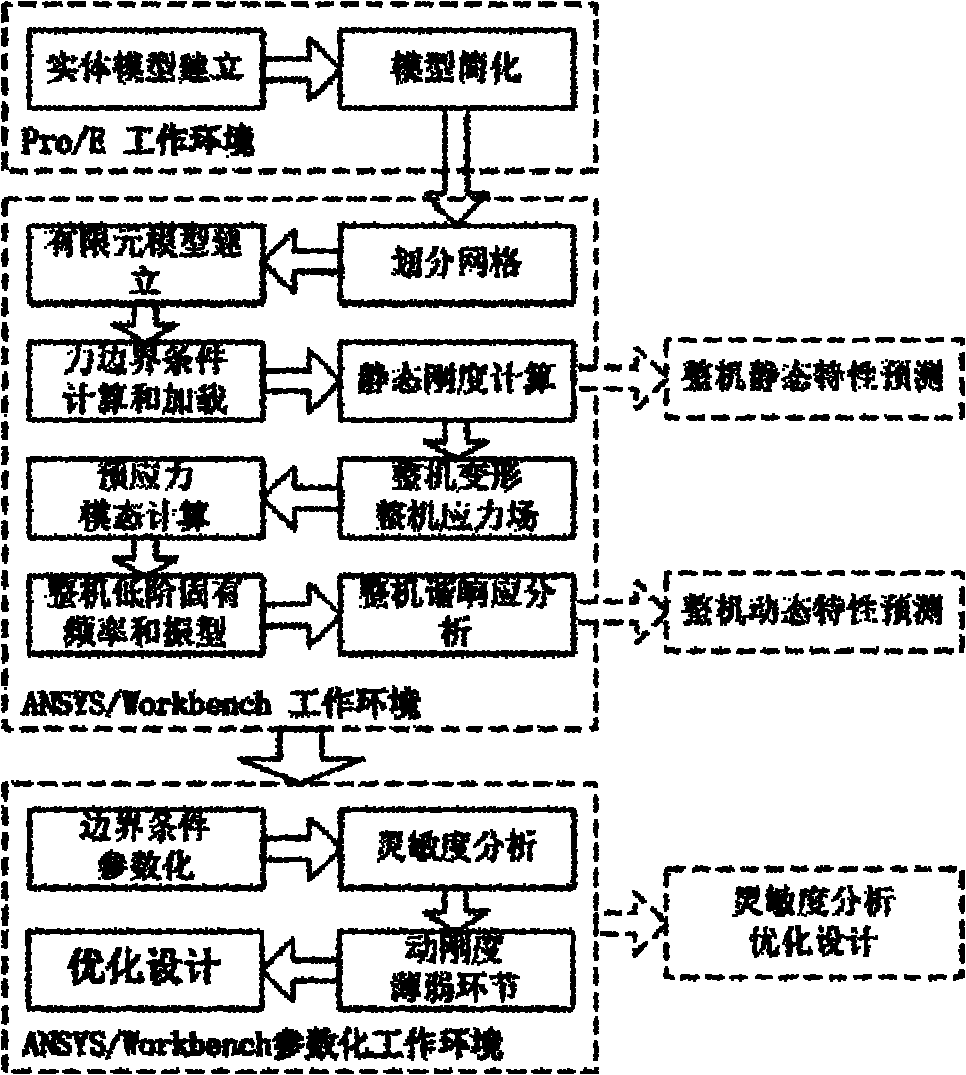

[0033] refer to figure 1 , the optimization design includes two parts: dynamic characteristic prediction and sensitivity analysis. According to the optimization design steps shown in the flow chart, the dynamic performance optimization of the whole machine tool can be realized. Taking the CNC boring and milling machine as an example, the entire design process and steps are described in detail.

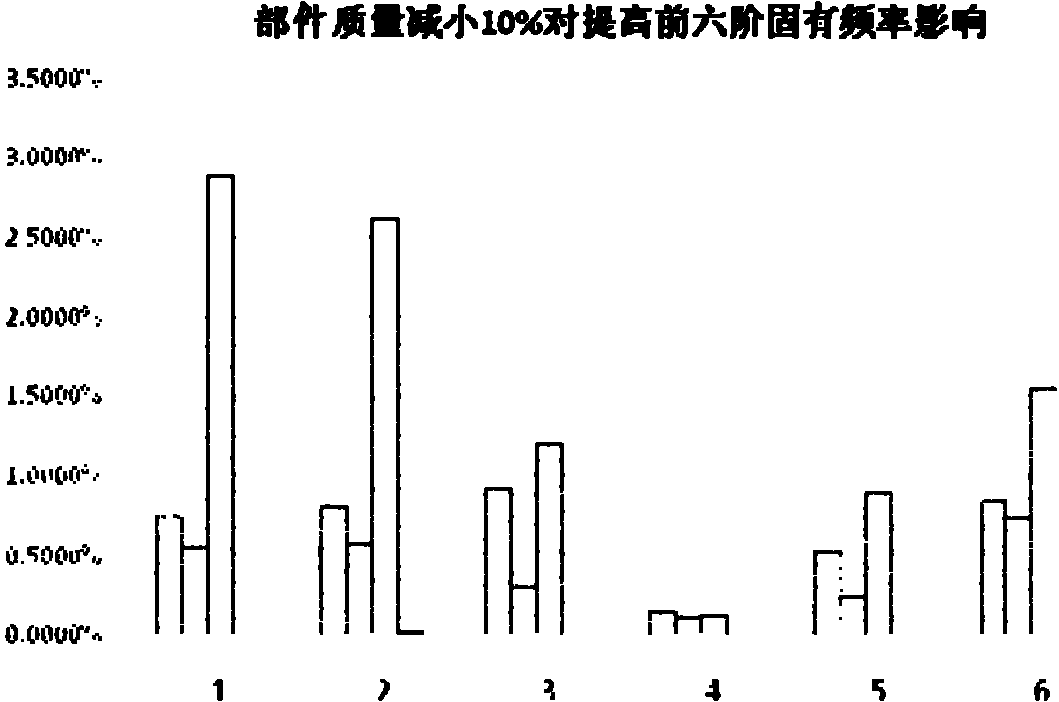

[0034] refer to figure 2 , is the influence of the quality characteristics of each main component on the first six natural frequencies of the whole machine. For the first three natural frequencies, the mass of the ram, ram seat and column has the greatest influence.

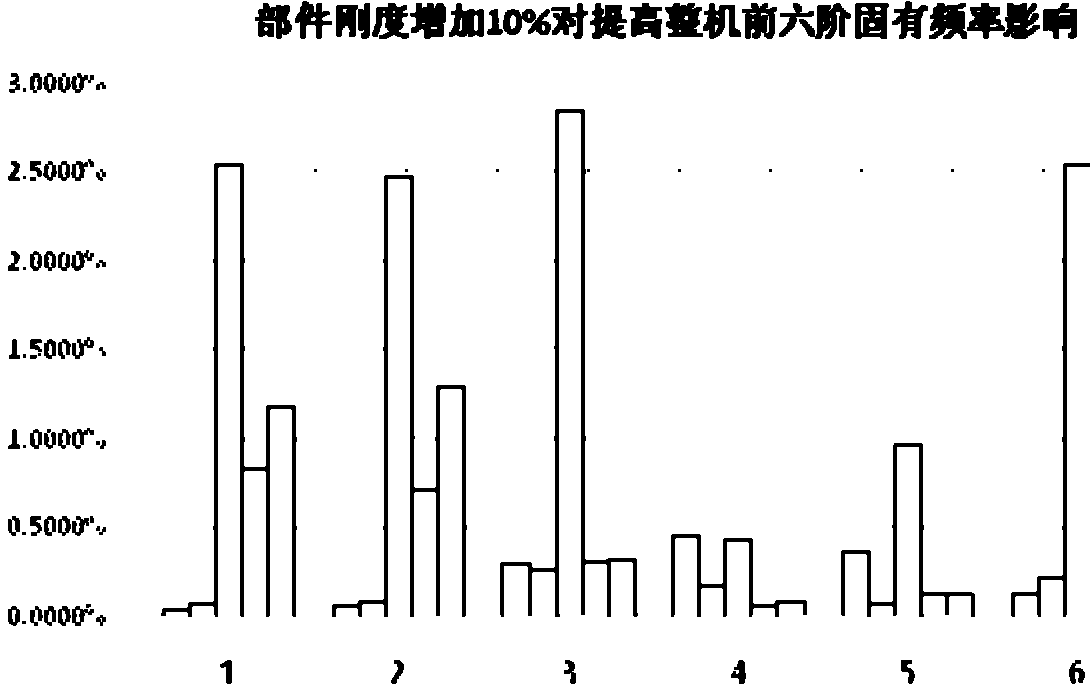

[0035] refer to image 3 , is the influence of the stiffness characteristics of each main component on the first six natural frequencies of the whole machine. For the first two natural frequencies, the column, sliding seat and bed have the greatest influence.

[0036] refer to Figure 4 , is the influence of the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com