Compact power module

A power module and compact technology, applied in the field of compact power modules, can solve the problems of low power density, large parasitic inductance of the internal power loop, and high height of the power module, so as to improve reliability, reduce parasitic inductance, reduce The effect of voltage overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

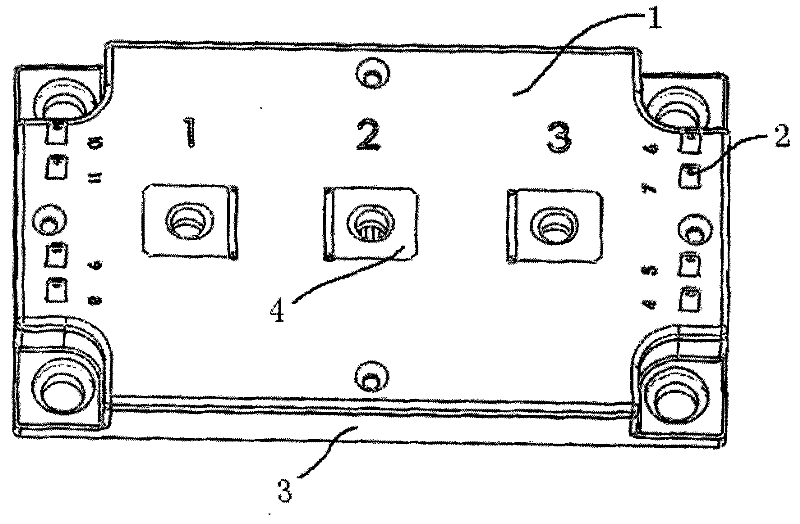

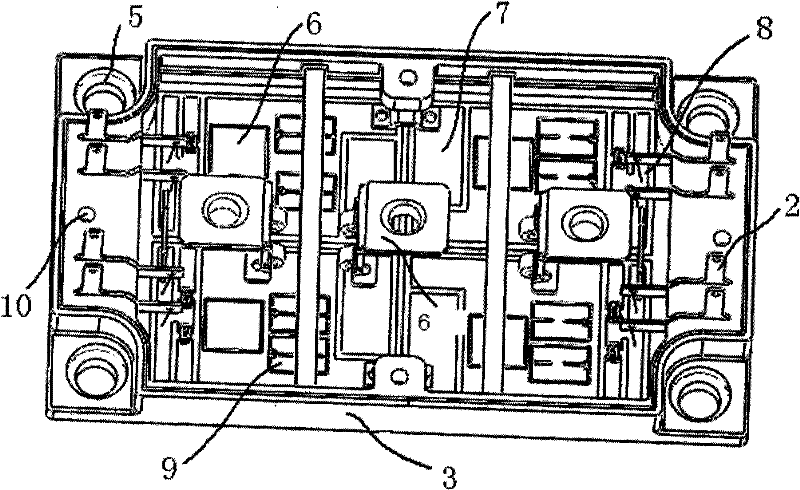

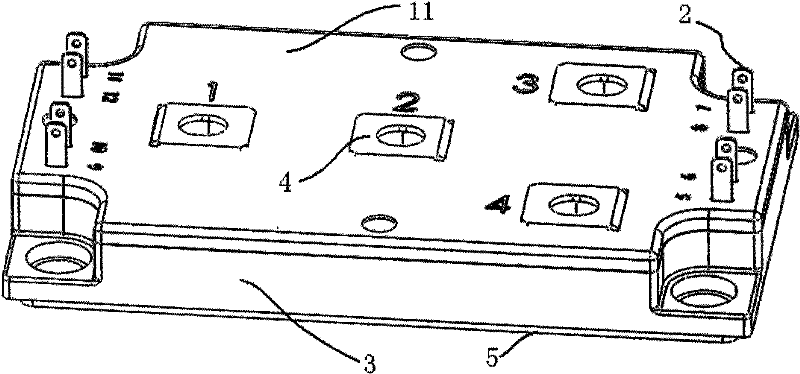

[0019] As shown in the figure, the present invention includes a copper heat dissipation substrate 5, a housing, and a circuit structure packaged in the housing. The casing includes a casing 3 and an outer cover 1 (or 11, or 14) covering the casing 3, and the circuit structure includes power terminals 4, signal terminals 2, insulating ceramic substrate 7, IGBT chips 9 (or 13), diode chip chips 6 (or 12). The insulating ceramic substrate 7 is welded on the copper heat dissipation substrate 5 by high-temperature reflow, and the insulating ceramic substrate 7 is welded with IGBT9 (or 13) and power diode 6 (or 12) chips, IGBT chip 9 (or 13), power diode 6 ( or 12) connect to the circuit structure etched on the insulating ceramic substrate 7, and connect the IGBT chip 9 (or 13) and the diode chip 6 (or 12) to each other through aluminum wires. At least thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com