Jet self-cleaning screen filter

A self-cleaning and filter technology, applied in the field of water treatment, can solve the problems of high equipment cost and complex self-cleaning control system of filters, and achieve the effects of low manufacturing cost, simplified automatic control system, and simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

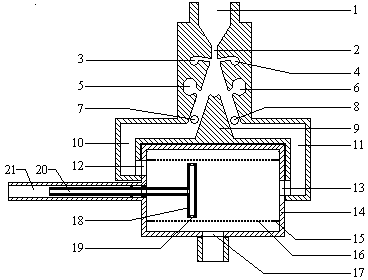

[0021] refer to figure 1 and figure 2 . The jet element consists of water flow input port 1, nozzle 2, control hole Ⅰ3, control hole Ⅱ4, emptying hole Ⅰ5, emptying hole Ⅱ6, signal hole Ⅰ7, signal hole Ⅱ8, splitter 9, output channel Ⅰ10, output channel Ⅱ11, Among them, the flow splitter 9 divides the flow channel into the output channel I10 and the output channel II11, the signal hole I7 and the control hole I3 are connected from the outside through the pipe to form the signal channel I, and the emptying hole I5 is on the left side wall of the output channel I10. The channel I10 is connected, and communicates with the sewage channel 21 from the outside through the pipeline; the signal hole II8 is connected with the control hole II4 through the external part of the pipeline to form the signal channel II, and the emptying hole II6 is on the right side wall of the output channel II11, and is connected with the output channel II. II11 communicates, and communicates with the sewa...

Embodiment 2

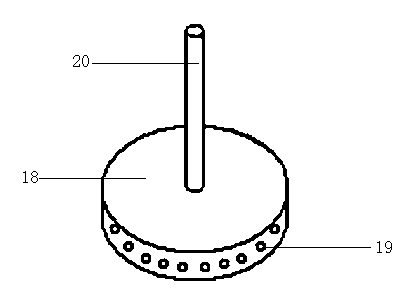

[0024] A jet self-cleaning screen filter shown in Example 2 has similar basic structural features to that of Example 1, the difference is that the sewage suction component is composed of a hollow circular thin cylinder and a sewage pipe, and the sewage suction holes are arranged on the circular column On the inner circumference of the body, more than two sewage pipes can be set and connected vertically to the bottom surface of the ring; the sewage suction assembly is outside the filter screen; the water inlet of the filter assembly is outside the filter screen, and the outlet of the filter assembly is on the outside of the filter screen Inside: The turbid water enters from the outside of the filter, and after being filtered by the filter, the clean water flows out from the inside of the filter.

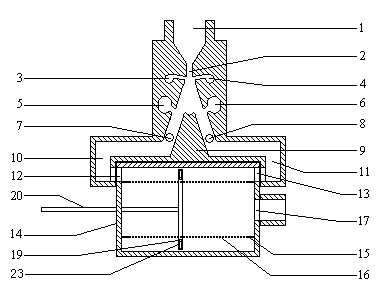

[0025] refer to image 3 and Figure 4 . The jet element consists of water flow input port 1, nozzle 2, control hole Ⅰ3, control hole Ⅱ4, emptying hole Ⅰ5, emptying hole Ⅱ6, signal ...

Embodiment 3

[0029] A jet self-cleaning screen filter shown in Example 3 has similar basic structural features to that of Example 1, the difference being that the emptying hole of the jet element is canceled; the filter assembly water inlet is arranged on the side of the filter assembly housing; the sewage discharge A water wheel 22 is installed at the tail end of the pipe 20, so that the blowdown assembly rotates while moving longitudinally.

[0030] refer to Figure 5 . The jet element is composed of water flow input port 1, nozzle 2, control hole I3, control hole II4, signal hole I7, signal hole II8, splitter 9, output channel I10, and output channel II11. The splitter 9 divides the flow channel into output channel I10 and output channel II11, the signal hole I7 is connected with the control hole I3 to form the signal channel I, and the signal hole II8 is connected to the control hole II4 to form the signal channel II.

[0031] The filter assembly is composed of the filter assembly wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com