Abrasion resistant malleable cast iron material and preparation method thereof

A technology of cast iron and iron wire, which is applied in the field of metal materials, can solve the problems of limited improvement of material wear resistance and insufficient toughness of wrought iron, and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

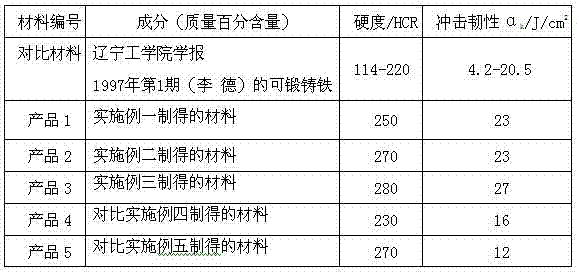

Examples

Embodiment 1

[0030] Preparation of nickel -plated high -carbon wire and nickel -plated iron wire:

[0031] The weight of the composition of high -carbon steel wire is: C is 0.55%, Si is 0.18%, MN is 0.45%, P <0.02%, S <0.02%, and the rest are Fe, and the diameter is 1mm.

[0032] The weight of the wire component is: C is 0.05%, Si is 0.2%, MN is 0.25%, P <0.02%, S <0.025%, the rest are Fe, and the diameter is 1mm.The overall length of the high -carbon wire and the wire is comparable, and the volume of the volume of the material to control high -carbon steel wires and iron wires is 5%.

[0033] High -carbon steel wires and iron wires are placed on the surface according to conventional methods, and the thickness of the nickel plating layer is 50 microns;

[0034] The preparation process is as follows:

[0035] According to the conventional method of cleaning balls, the above nickel -plated high -carbon steel wire and nickel -plated iron wire are taken each to form a spherical mixed dual -wire me...

Embodiment 2

[0039] The composition of the forged cast iron material substrate is based on weight: C is 2.4%, Si is 1.3%, MN is 0.6%, ZR is 1%, P <0.08%, S <0.25%, and the rest are ingredients for FE.

[0040] Preparation of nickel -plated high -carbon wire and nickel -plated iron wire:

[0041] The weight of the composition of high -carbon steel wire is: C is 0.8%, Si is 0.21%, MN is 0.65%, P <0.02%, S <0.02%, and the rest are Fe; diameter is 2mm.

[0042] The weight of the wire component is: C is 0.09%, Si is 0.3%, MN is 0.35%, P <0.02%, S <0.025%, and the rest are Fe; diameter is 2mm.

[0043] The overall length of the high carbon wire and the wire is equal, and the volume percentage of high -carbon steel wires and iron wires accounts for 40%.

[0044]High -carbon steel wires and iron wires are placed on the surface according to conventional methods, respectively, respectively, respectively, respectively nickel -plated high -carbon steel wires and nickel -plated iron wires. The thickness of...

Embodiment 3

[0047] The composition of the forged cast iron material substrate is based on weight: C is 2.3%, Si is 1.2%, MN is 0.5%, ZR is 0.7%, P <0.08%, S <0.25%, and the rest are ingredients for FE.

[0048] Preparation of nickel -plated high -carbon wire and nickel -plated iron wire:

[0049] The weight of the composition of high -carbon steel wire is: C is 0.7%, Si is 0.19%, MN is 0.55%, P <0.02%, S <0.02%, and the rest are Fe; diameter is 1.2mm.

[0050] The weight of the composition of the wire is: C is 0.07, Si is 0.25%, MN is 0.3%, P <0.02%, S <0.025%, and the rest are Fe; diameter is 1.2mm.

[0051] The overall length of the high -carbon wire and the wire is comparable. The percentage of the volume of the material between the high -carbon steel wire and the wire is 25%.

[0052] High -carbon steel wires and wire are plated nickelly on the surface according to conventional methods, and the thickness of the nickel -plated layer is 200 microns; the conventional methods of cleaning ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com