Microbial multi-cycle huff and puff oil production method

A microbial and round technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of scrapping, poor steam injection effect, short production time, etc., and achieve simple construction technology, high oil production efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

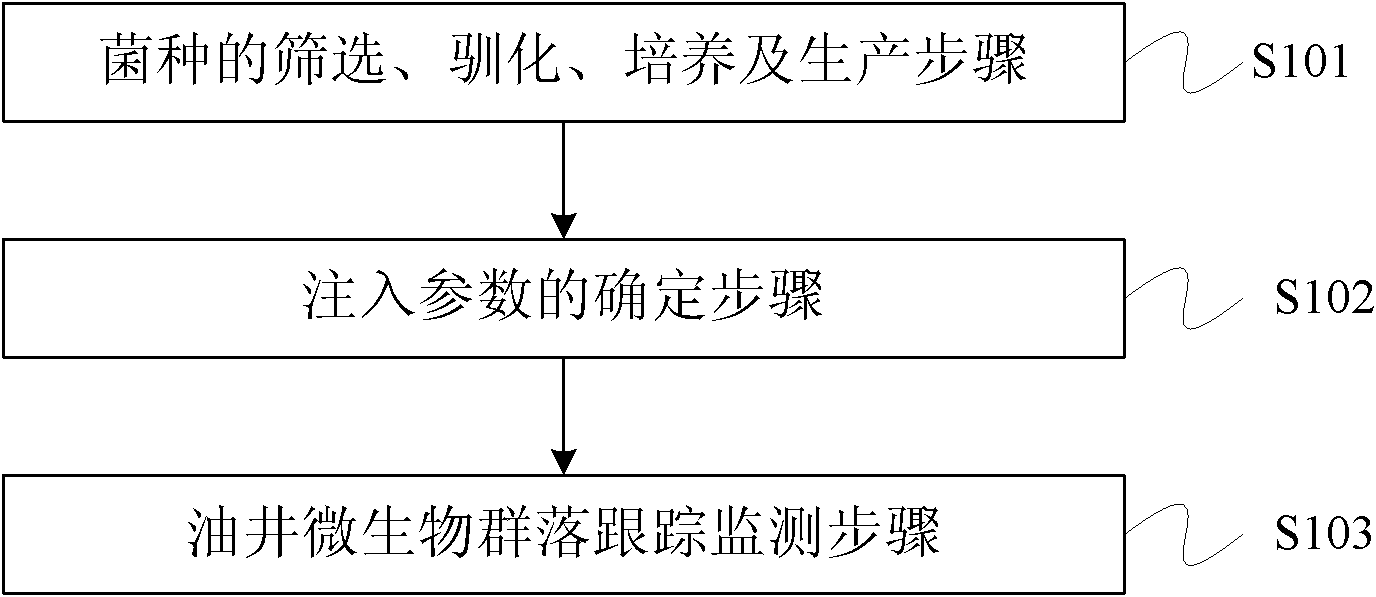

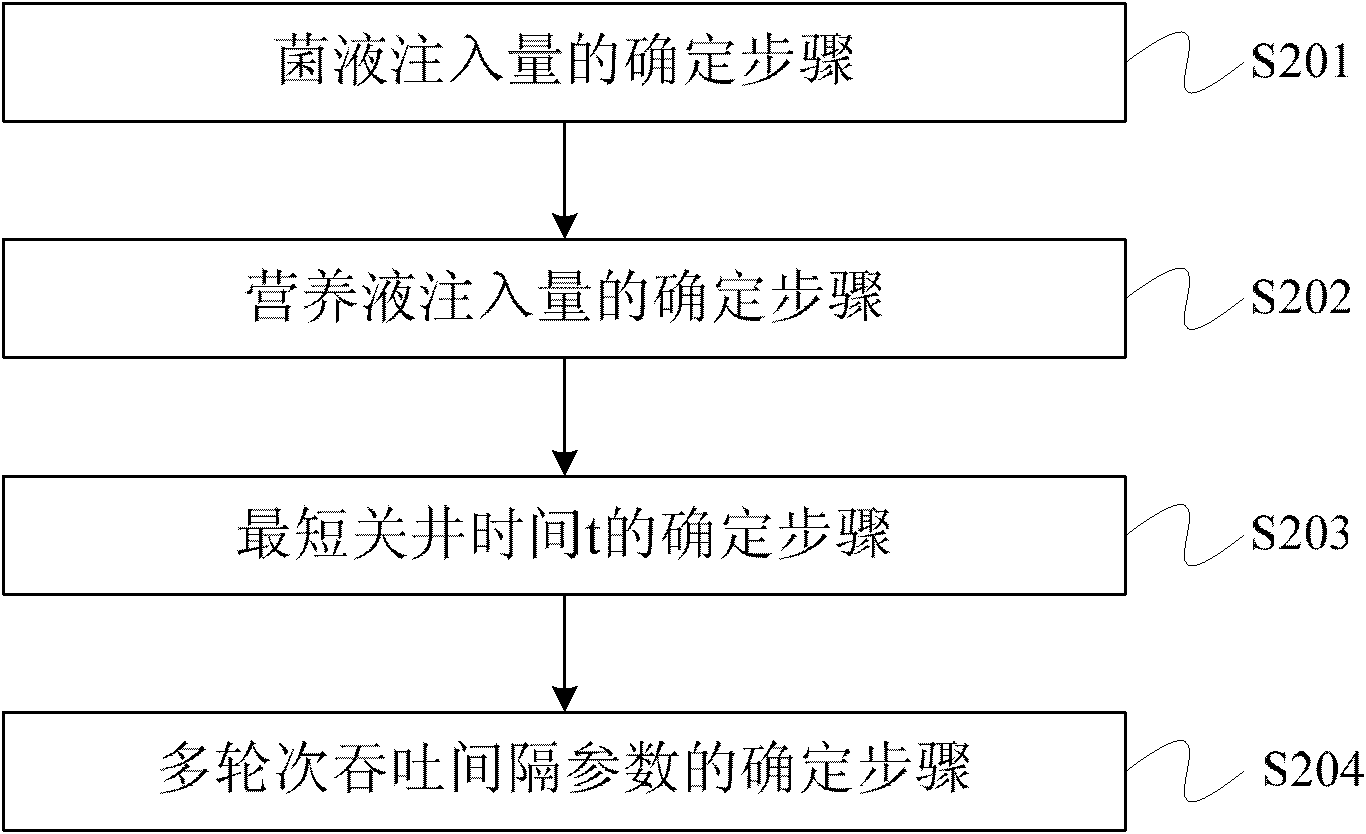

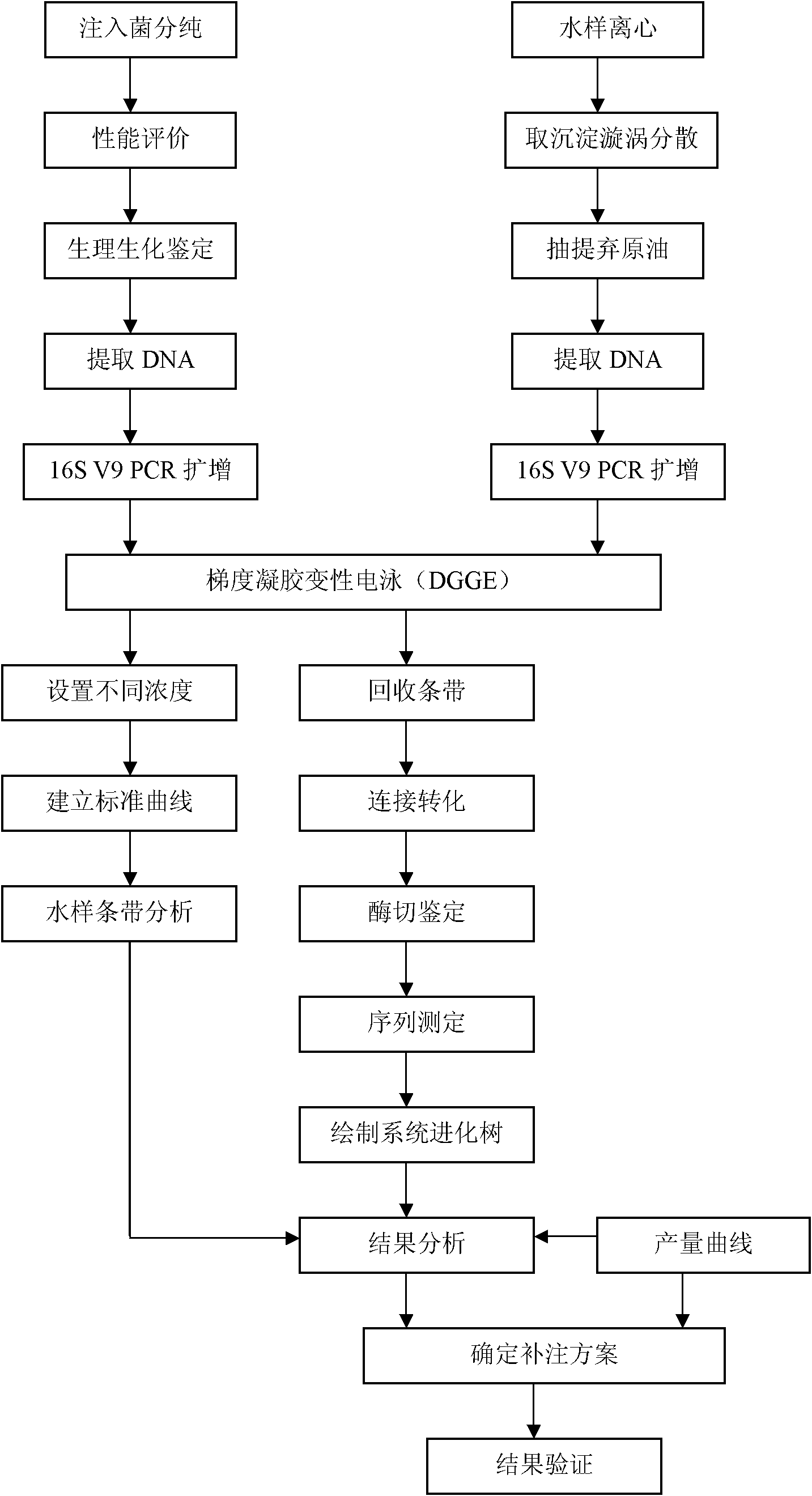

[0027] like figure 1 As shown, the microbial multi-round huff and puff oil recovery method in this embodiment includes: strain screening, domestication, cultivation and production steps, selecting a mixed strain LJ comprising Ochrobactrum sp. and Rhodococcus ruber, The mixed strains LJ were separated, and the colony and cell morphology of Paleobacterium pallidum and Rhodococcus rubrum in the mixed strains were obtained, and each strain was identified as a genus, and the strains were respectively placed on the LB plate Dilution coating S101; the step of determining th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com