Oil-gas well fiber assisted water control fracturing method

A technology for oil and gas wells and auxiliary control, which is applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc. The effects of preventing sand plugging and proppant backflow, reducing water permeability and improving sand-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A fiber-assisted water control fracturing method for oil and gas wells, the steps are as follows:

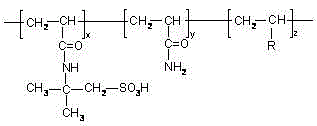

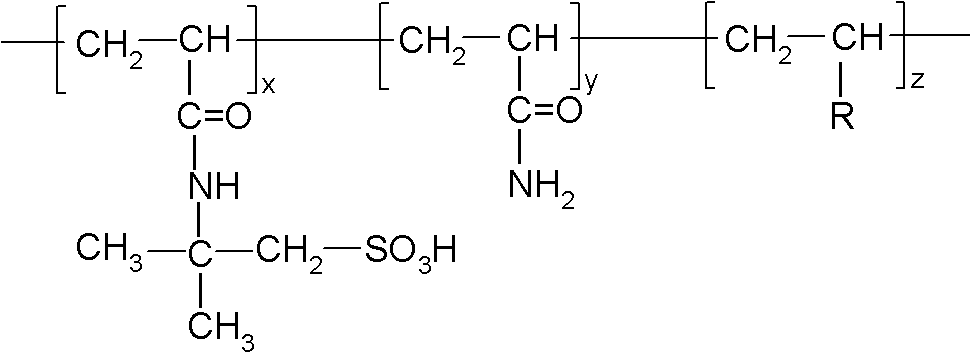

[0029] (1) Add 10000kg of water to a container with pump circulation or agitator, then turn on the pump circulation, slowly add 20kg of thickener with water control function, then add 100kg of clay stabilizer, 30kg of pH regulator, 30kg of fracturing fluid After the fungicide and 50kg drainage aid, continue to circulate for 30 minutes to fully swell and mix the liquid to form a low-viscosity liquid, which is the fracturing fluid;

[0030] (2) 1 / 2 of the fracturing fluid prepared in step (1) is mixed evenly with 40kg of fibers (fiber monofilament diameter is 10-15 microns and length is 8-12 mm) to obtain the fracturing sand-carrying fluid;

[0031] (3) Mix the fracturing sand-carrying fluid prepared in step (2) with 2000kg of proppant, and stir to form a sand-mixing fluid;

[0032] (4) First pump 1 / 2 of the fracturing fluid prepared in step (1) into the target layer in th...

Embodiment 2

[0035] The fiber-assisted water control fracturing method for oil and gas wells as described in Example 1, the difference is that

[0036] The add-on of the thickening agent in the step (1) is 30kg;

[0037] 2 / 3 of the fracturing fluid in the step (2) is mixed with 60kg of fibers (fiber monofilament diameter is 10-15 micron, length is 8-12 mm);

[0038] The addition amount of the proppant in step (3) is 3000kg.

[0039] According to the standards issued by the Ministry of Petroleum SY / T 6339-1998 "Unsteady State Method for Determination of Relative Permeability of Oil and Gas" and SY / T 5345-1999 "Determination of Relative Permeability of Oil and Water", after actual testing, the water phase permeability can be reduced by 70%. Above, the reduction rate of oil and gas phase permeability is controlled within 15%, and the distance from cracks extending to the edge and bottom water layer is reduced by more than 70%.

Embodiment 3

[0041] The fiber-assisted water control fracturing method for oil and gas wells as described in Example 1, the difference is that

[0042] The add-on of the thickening agent in the step (1) is 40kg;

[0043] 3 / 4 of the fracturing prefluid in step (2) is mixed with fibers (fiber monofilament diameter is 10-15 micron, length is 8-12 mm), and the addition amount of fiber is 80kg;

[0044] The addition amount of the proppant in step (3) is 4000kg.

[0045] According to the standards issued by the Ministry of Petroleum SY / T 6339-1998 "Unsteady State Method for Determination of Relative Permeability of Oil and Gas" and SY / T 5345-1999 "Determination of Relative Permeability of Oil and Water", after actual testing, the water phase permeability can be reduced by more than 80%. , while the reduction rate of the oil and gas phase permeability is controlled within 20%, and the distance from the fracture to the bottom water layer is reduced by more than 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com