Ni-based single crystal superalloy and alloy member using the same as base

A superalloy and single crystal technology, which is applied in Ni-based single crystal superalloy and alloy components, can solve the problems of TCP phasor increase, creep strength decrease, Ni-based single crystal superalloy development difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

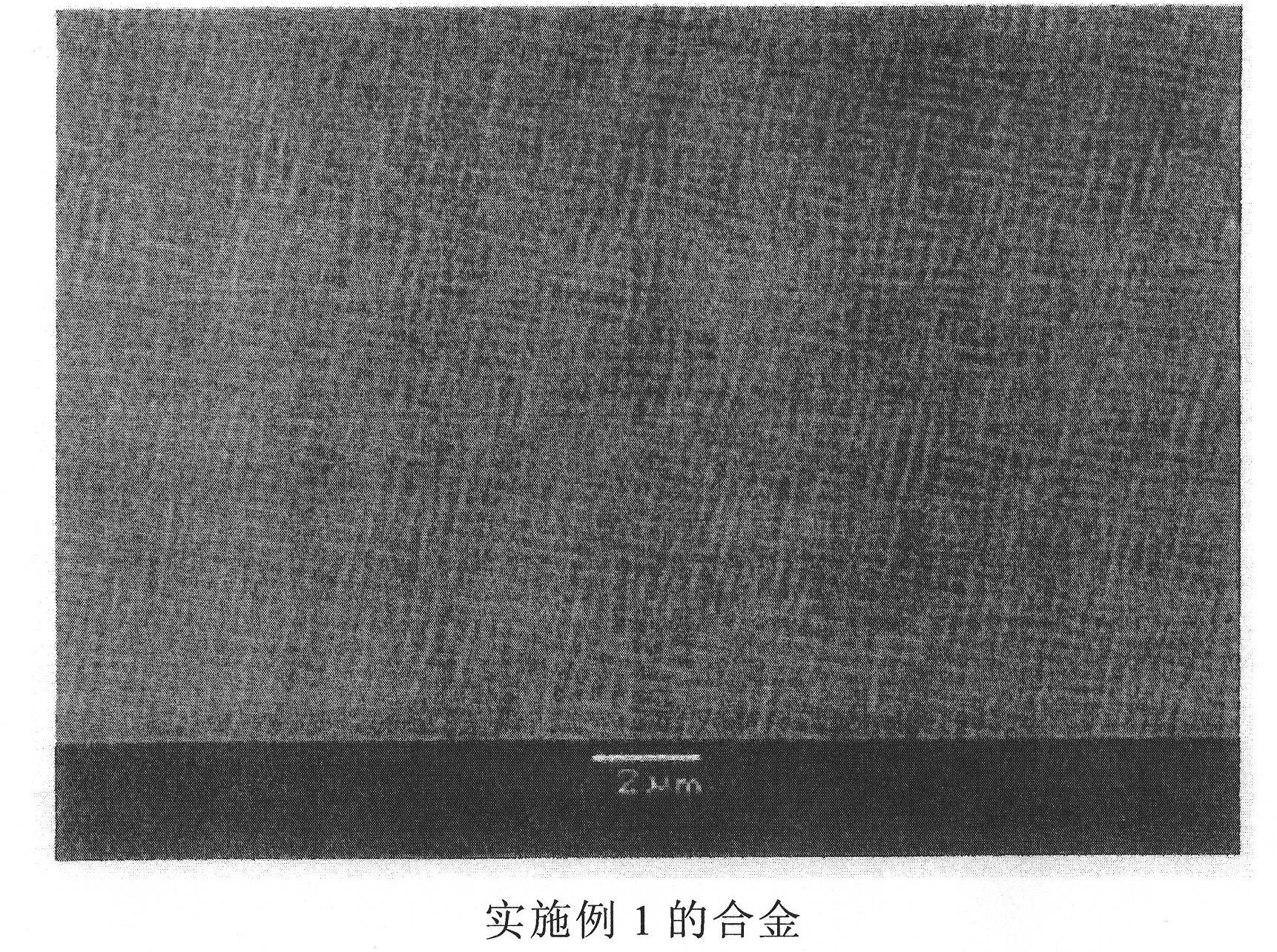

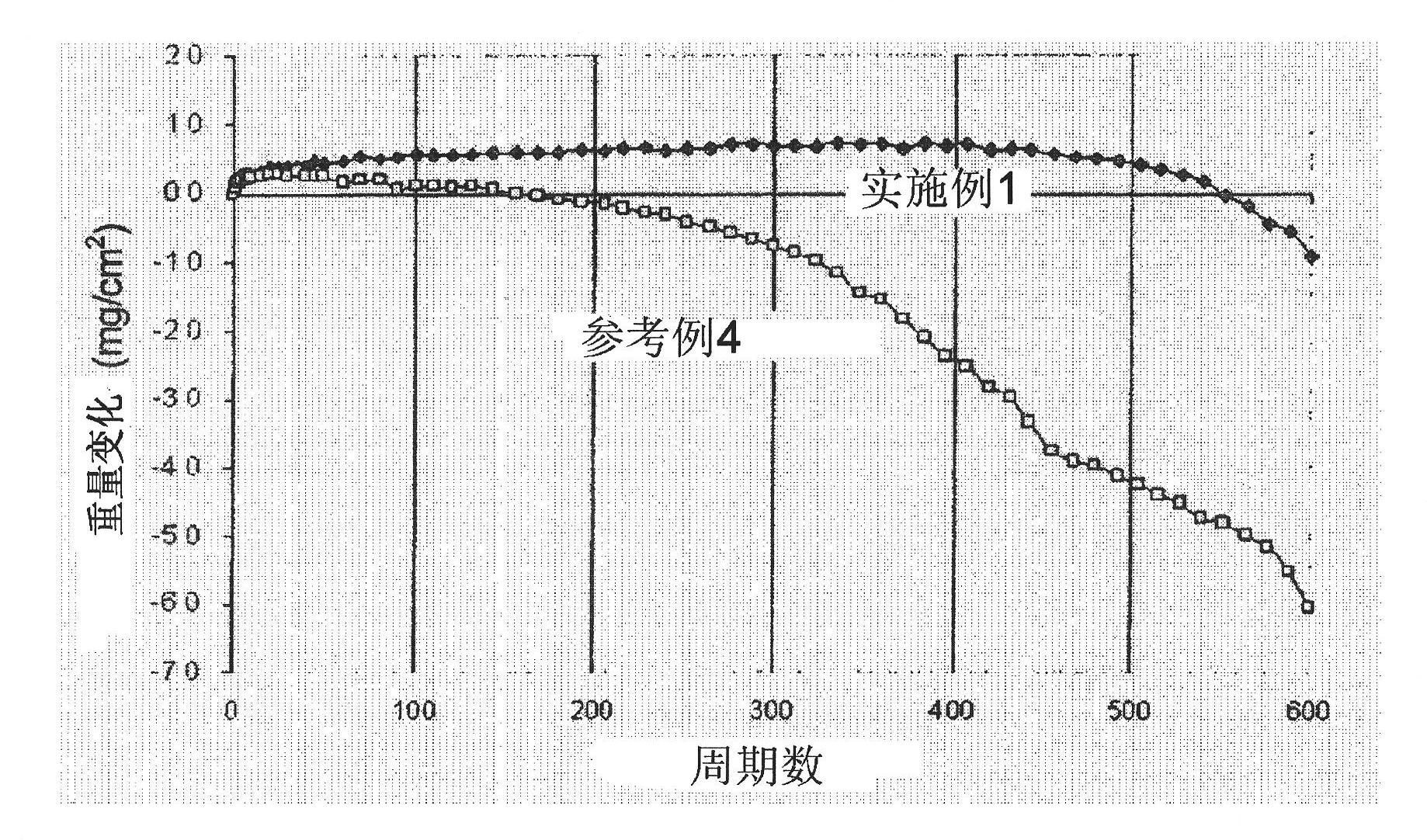

[0041] Embodiments of the present invention will be described in detail below.

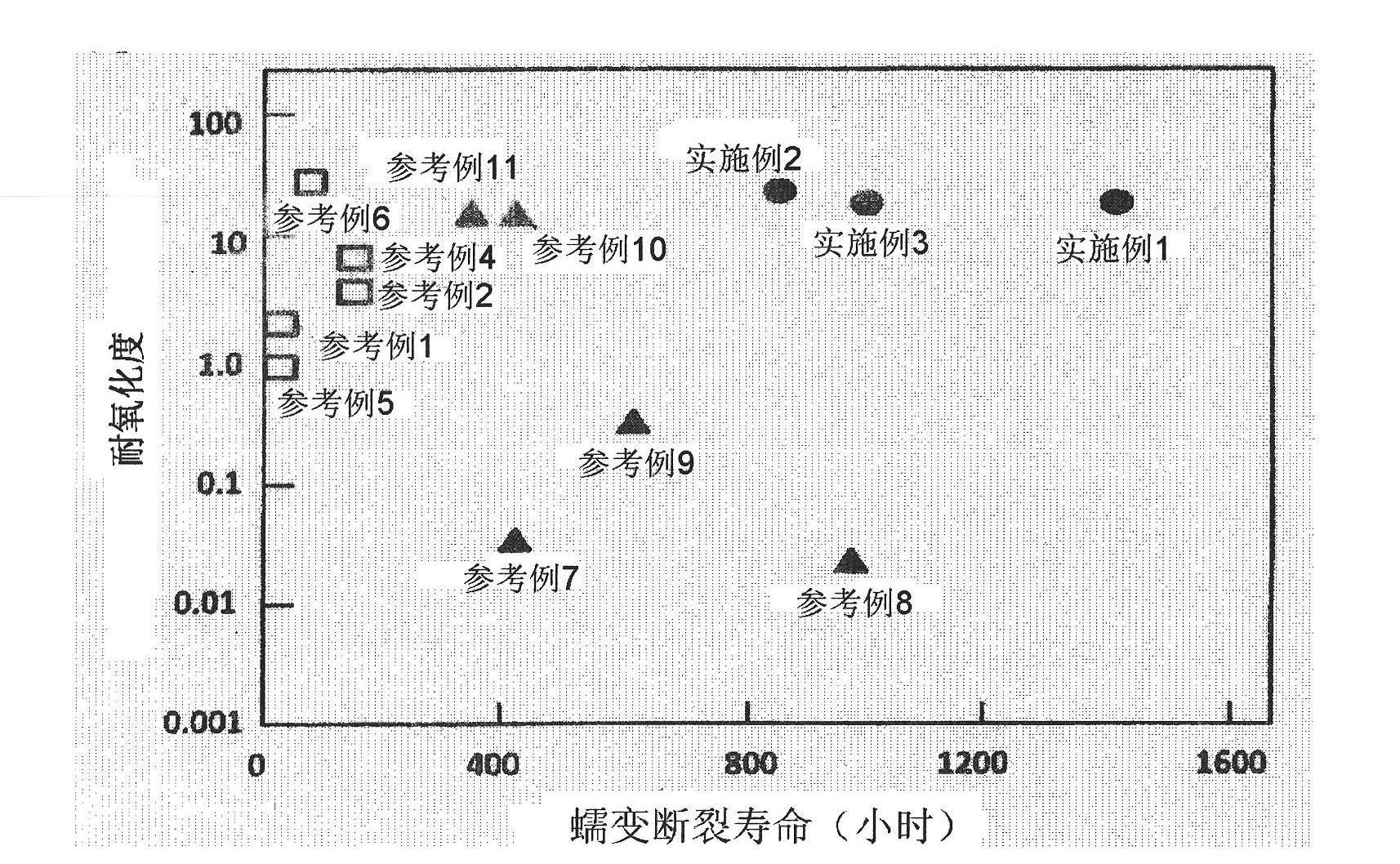

[0042] The Ni-based single crystal superalloy of the present invention is an alloy in which Al, Ta, W, Re, Cr, Ru, and Nb are main additives, and Mo, Hf, and Co are used as adjustment additive elements.

[0043] The Ni-based single crystal superalloy of the present invention is characterized by having the following composition, that is, the mass ratio of the components contained therein is as follows: Al: 5.0 mass % to 7.0 mass %, Ta: 4.0 mass % to 8.0 mass %, Mo : 0 mass % to 2.0 mass %, W: 3.0 mass % to 8.0 mass %, Re: 3.0 mass % to 8.0 mass %, Hf: 0 mass % to 0.50 mass %, Cr: 3.0 mass % to 7.0 Mass % or less, Co: 0 mass % to 9.9 mass %, Ru: 1.0 mass % to 14.0 mass %, Nb: 0.1 mass % to 4.0 mass %, and the remainder consists of Ni and unavoidable impurities.

[0044] The Ni-based single crystal superalloy of the present invention is characterized by having the following composition, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com