Trap lamp powder, trap lamp using trap lamp powder and method for manufacturing trap lamp

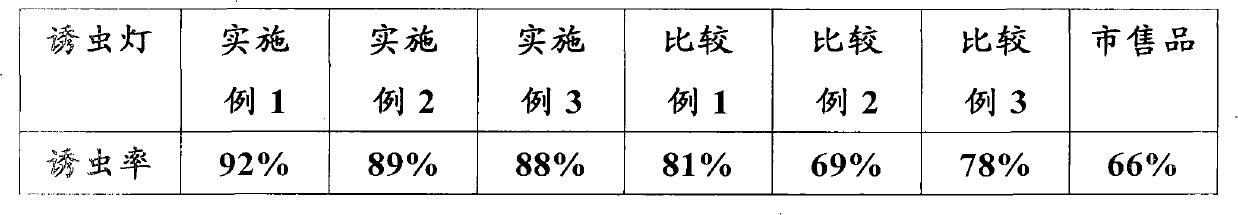

An insect trapping lamp and insect trapping powder technology are applied in the device, application, animal husbandry and other directions of catching or killing insects, and can solve the problem that the insect trapping efficiency needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Manufacturing of insect trap lamp

[0039] 1. The formula for powder coating of the trap lamp is as follows:

[0040] Full spectrum 75 parts by weight of insect attracting powder

[0041] Full spectrum 25 parts by weight of ultraviolet phosphor

[0042] 5 parts by weight of broad-spectrum rare earth blue powder

[0043] 2. The manufacturing of the trap lamp adopts typical methods:

[0044] a) The potassium barium material glass tube that has been cleaned and dried with 10% hydrofluoric acid solution ( Pipe wall thickness 0.7mm) sent to the powder coating machine;

[0045] b) In an environment with a relative humidity of about 60% and a temperature of about 28°C, apply powder to the glass tube for the insect trap lamp, and the insect trap lamp powder is formulated with water to form a suspension with a solid content of 10% by weight Liquid, stir at any time to avoid deposition;

[0046] c) Dry the glass tube coated with insect trap lamp powder at about 450℃, and remove...

Embodiment 2

[0048] Example 2: Manufacturing of insect trap lamp

[0049] 1. The formula for powder coating of the trap lamp is as follows:

[0050] Full spectrum Insect attract powder 70 parts by weight

[0051] Full spectrum 30 parts by weight of ultraviolet phosphor

[0052] Full-spectrum rare earth blue powder 2 parts by weight

[0053] 2. Refer to Example 1 for the manufacture of insect trap lamps.

Embodiment 3

[0054] Example 3: Manufacturing of insect trap lamp

[0055] 1. The formula for powder coating of the trap lamp is as follows:

[0056] Full spectrum 80 parts by weight

[0057] Full spectrum Ultraviolet phosphor 20 parts by weight

[0058] Full-spectrum rare earth blue powder 8 parts by weight

[0059] 2. Refer to Example 1 for the manufacture of insect trap lamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com