Long-acting combination type wound dressing and preparation method thereof

A wound dressing and combined technology, which is applied in medical science, absorbent pads, bandages, etc., can solve the problems of long onset time, short duration, fast degradation, etc., and achieve the effect of short onset time and long action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

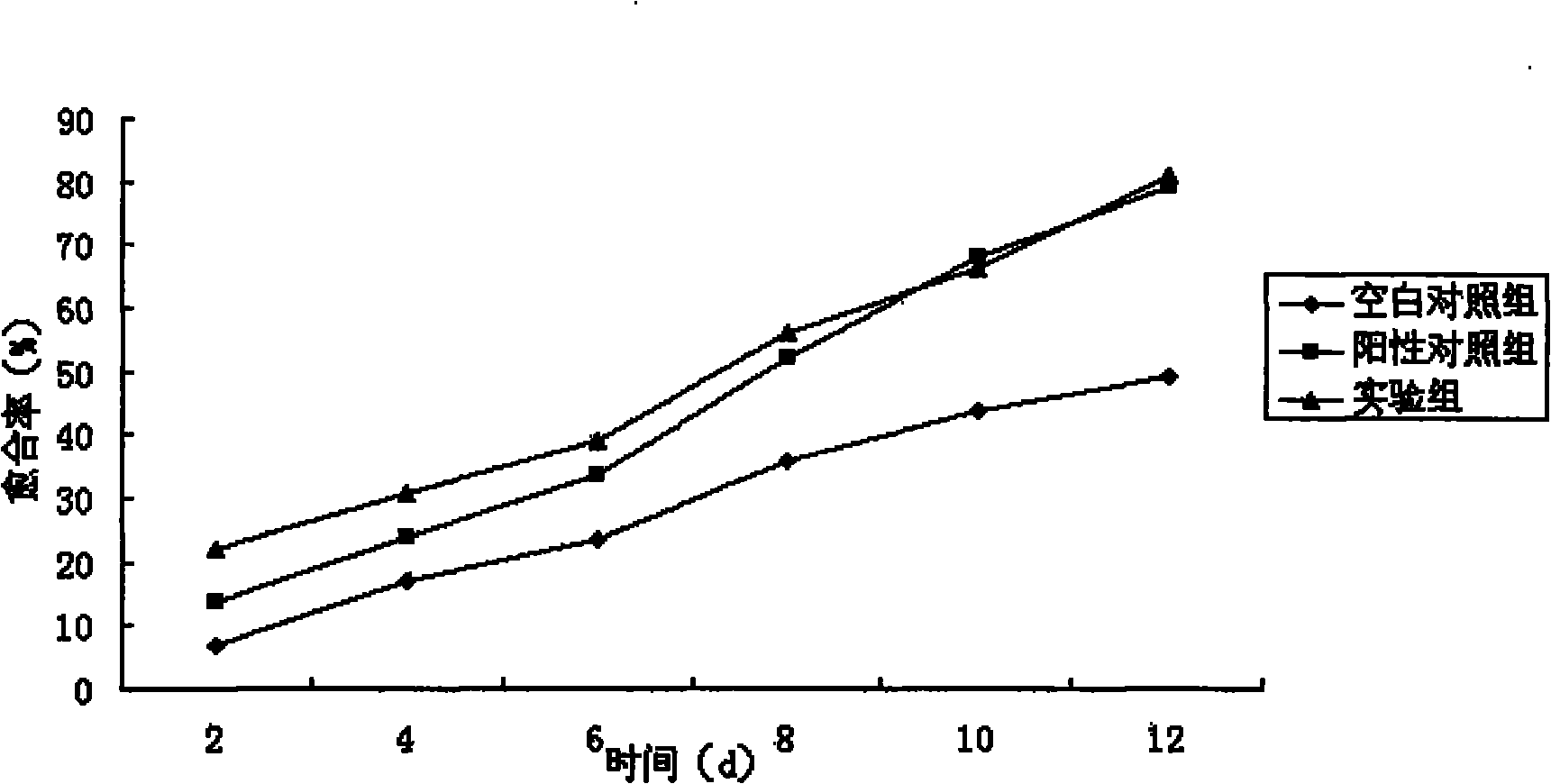

Embodiment 1

[0025] Example 1: Accurately weigh 0.5 g of chitosan and place it in a stirrer, add 100 ml of purified water, add 0.4 ml of glacial acetic acid dropwise, and stir evenly at a stirring speed of 65 r / min until it is completely dissolved and becomes a homogeneous solution. Add 6 grams of gelatin to the solution, heat it on a 75°C water bath until the gelatin is completely dissolved, then add 1.5 grams of chitooligosaccharides and 10 grams of chitooligosaccharides and stir to dissolve them. The stirring speed is 150r / min. Then add 1 ml of glycerin and stir evenly until it is completely dissolved. The stirring speed is 100r / min and the pH is controlled to 6.5. Finally, filter and remove impurities, stand for defoaming, and sterilize separately, which is the finished product.

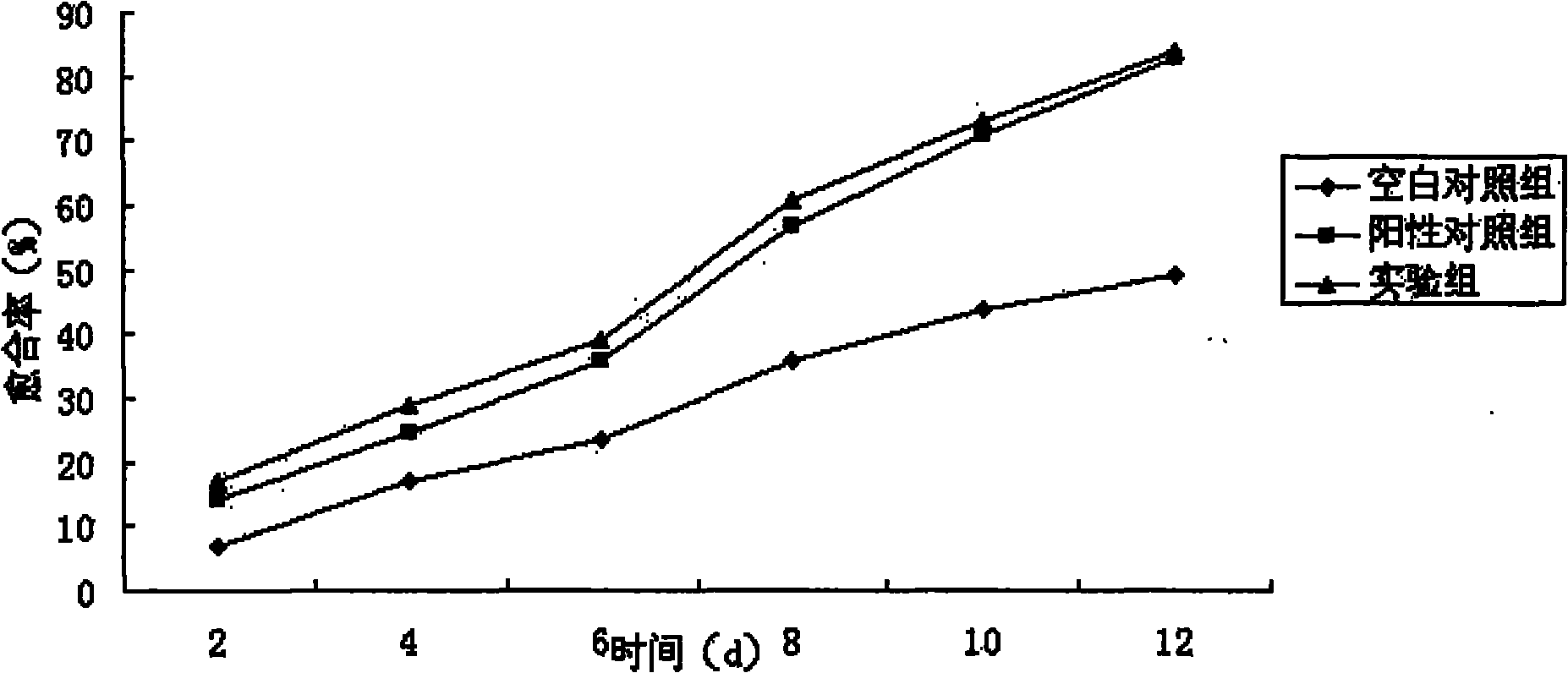

Embodiment 2

[0026] Example 2: Accurately weigh 2 grams of chitosan and place it in a stirrer, add 100 ml of purified water, add 1 ml of glacial acetic acid dropwise, and stir evenly at a stirring speed of 150 r / min until it is completely dissolved and becomes a uniform solution. Add 4 grams of gelatin to the solution, heat it on a water bath at 75°C until the gelatin is completely dissolved, and then add 4 grams of chitooligosaccharides and 6 grams of chitooligosaccharides and stir to dissolve them. The stirring speed is 150r / min. Then add 4 ml of glycerin and stir evenly until it is completely dissolved. The stirring speed is 100r / min, and the pH is controlled to 5.5. Finally, filter and remove impurities, stand for defoaming, and sterilize separately, which is the finished product.

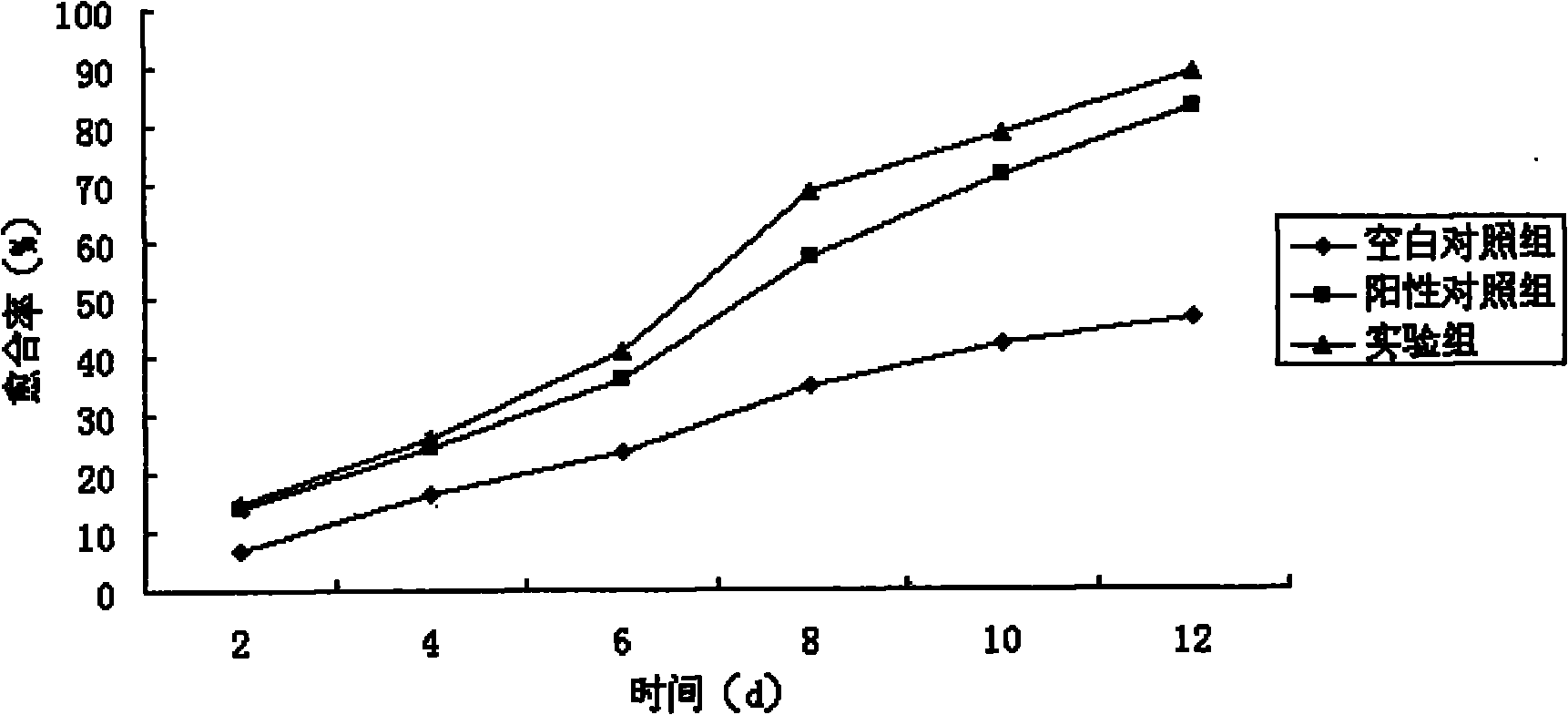

Embodiment 3

[0027] Example 3: Accurately weigh 4 grams of chitosan into a stirrer, add 100 ml of purified water, add 3 ml of glacial acetic acid dropwise, and stir evenly at a stirring speed of 200 r / min until it is completely dissolved and becomes a uniform solution. Add 2 grams of gelatin to the solution, heat it on a water bath at 75°C until the gelatin is completely dissolved, then add 6 grams of chitooligosaccharides and 2 grams of chitooligosaccharides and stir to dissolve them at a stirring speed of 150r / min. Then add 6 ml of glycerin and stir evenly until it is completely dissolved. The stirring speed is 100r / min, and the pH is controlled to 5. Finally, filter and remove impurities, stand for defoaming, and sterilize separately, which is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com