Varnish filter

A filter and varnish technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of poor filter treatment effect, poor water solubility of varnish, secondary pollution, etc. Small size, easy operation and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

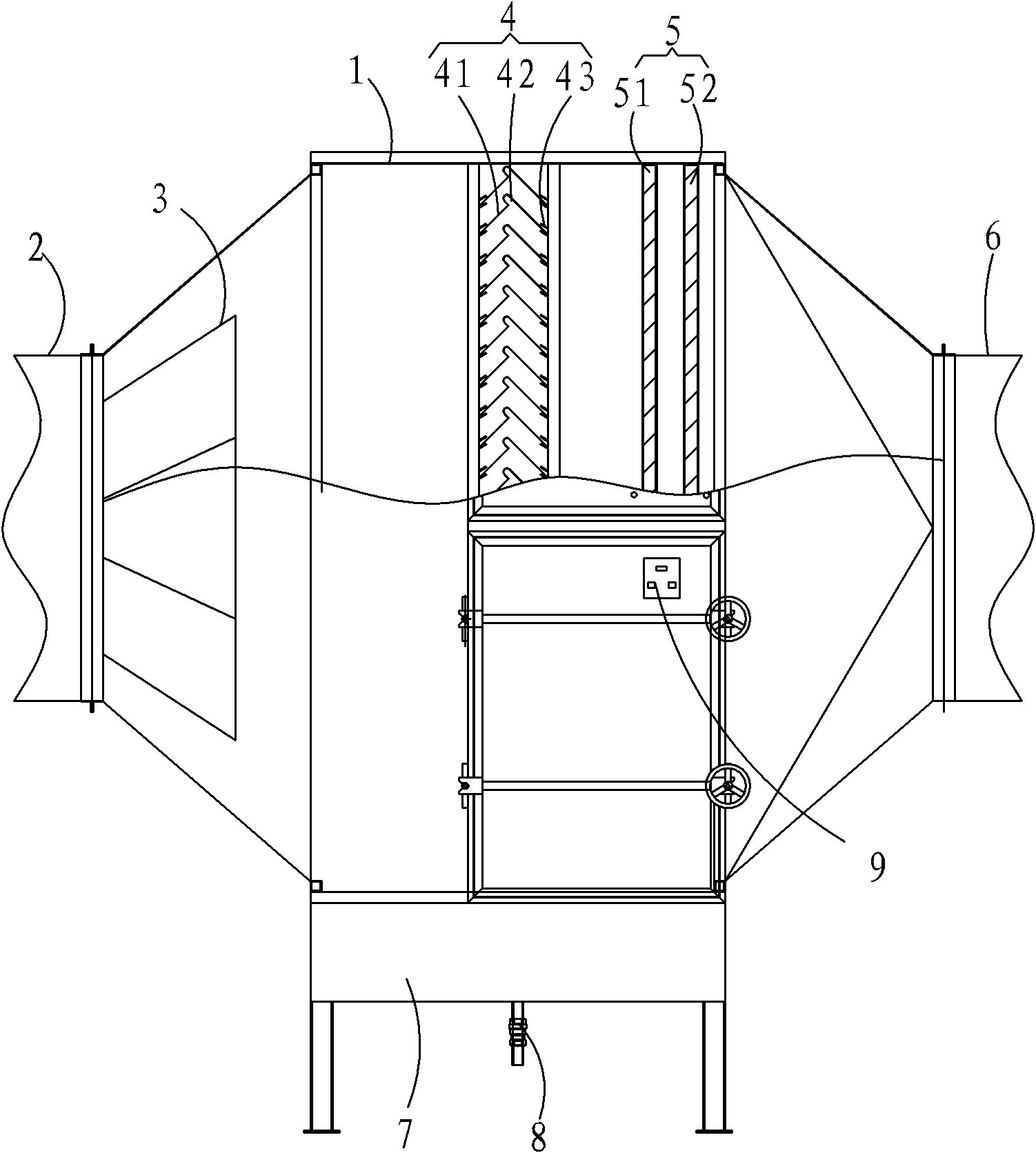

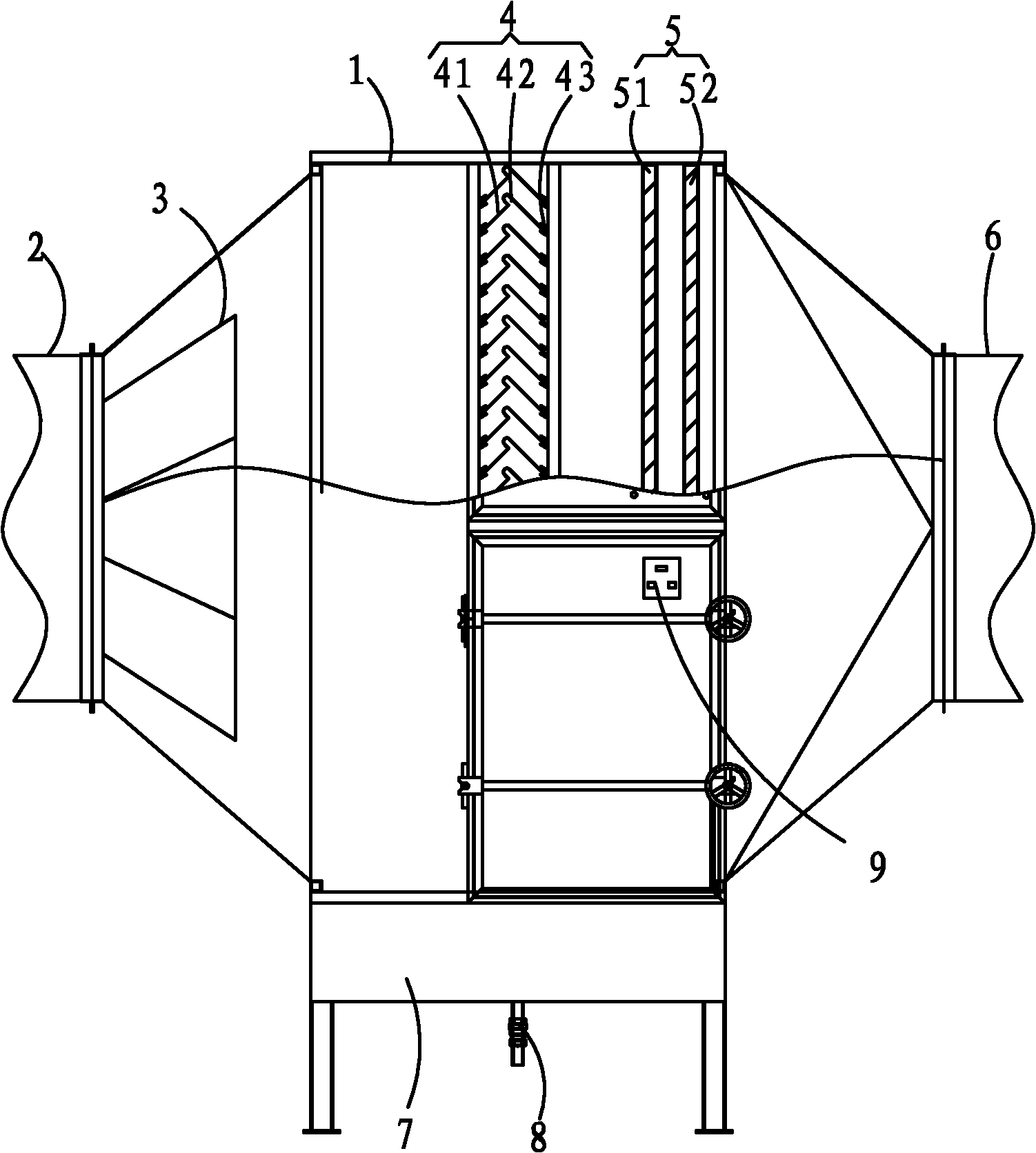

[0015] like figure 1 As shown in the figure, the varnish filter includes a housing 1. The housing 1 is sequentially provided with an air inlet 2, an air distribution device 3, a baffle blocking layer 4, a combined filter screen 5, and an air outlet 6 from the front end to the rear end. .

[0016] An oil collecting tank 7 is arranged at the inner bottom of the housing 1 , and an oil draining device 8 is arranged at the bottom of the oil collecting tank 7 .

[0017] The baffle-blocking layer 4 is composed of a plurality of equidistantly spaced inverted V-shaped baffles 41 , which are evenly arranged in the casing 1 from top to bottom. A protrusion 42 is provided on the top of the inverted V-shaped baffle 41 .

[0018] The combined filter screen 5 includes two layers, the filter screen layer 51 near the air outlet 1 is composed of multiple layers of wire meshes with different meshes, and the filter screen layer 52 near the air outlet 6 is composed of multiple layers of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com